Insights

With over 40 years of manufacturing expertise, AOK delivers highly customized sealing solutions that meet global automotive standards for quality, durability, and precision.

2025-08-01 15:18:45

Polariod Enterprise Co., Ltd. (Yieashang) focuses on the research, development, and production of plastic products and construction protective materials. With years of professional expertise and market experience, it is dedicated to providing high-performance, environmentally friendly products that meet industry standards, becoming an indispensable quality partner at construction sites.

2025-08-01 15:20:07

As vehicle electronics continue to evolve, driver safety now hinges not only on advanced systems like ADAS but also on the reliability of foundational components—such as wiper switches, brake light switches, and power window switches. These switches may seem simple, but their role is critical: ensuring real-time responsiveness, visibility, and control under all driving conditions. This article explores how such components contribute to vehicle safety and highlights Hung Yii Auto Parts as a specialized manufacturer delivering dependable OEM/ODM solutions.

2025-08-01 14:46:40

Blow molding is a specialized forming technology used to produce hollow plastic products. Its applications span across food packaging, daily chemical products, medical containers, automotive parts, and more. According to different molding methods, blow molding machines can be broadly categorized into extrusion blow molding, injection blow molding, stretch blow molding, and the rapidly growing automated all-electric blow molding technology in recent years. These technologies each offer advantages in material usage, product size, molding precision, and production line efficiency, allowing companies to choose the most suitable machine type based on product requirements and budget.

2025-08-01 14:43:19

Founded in 1992 and located in Miaoli, Taiwan, Elysian is a professional OEM/ODM manufacturer specializing in yoga mats, Pilates mats, treadmill mats, tool box mats, and various anti-slip mats. With strong R&D capabilities and advanced manufacturing equipment, the company is dedicated to providing diverse fitness mat products that meet international safety standards, renowned for their eco-friendliness and high quality.

2025-08-01 14:22:03

Steady Global Market Growth As of 2024, the global plastic blow molding machine market is valued at approximately USD 3.18 billion, and it is projected to reach around USD 4.05 billion by 2030, with a compound annual growth rate (CAGR) of about 4.2%. Other reports estimate the market will grow from around USD 3 billion in 2025 to USD 8 billion by 2032, with a CAGR between 3.9% and 4.1%. Asia-Pacific as the Leading Region The Asia-Pacific region accounts for approximately 39–40% of the global market share, already reaching 38.2% in 2023. China and Taiwan are the primary growth drivers. Taiwan’s blow molding machine exports account for 9% of its plastic and rubber machinery exports, showing double-digit growth.

2025-08-01 14:08:53

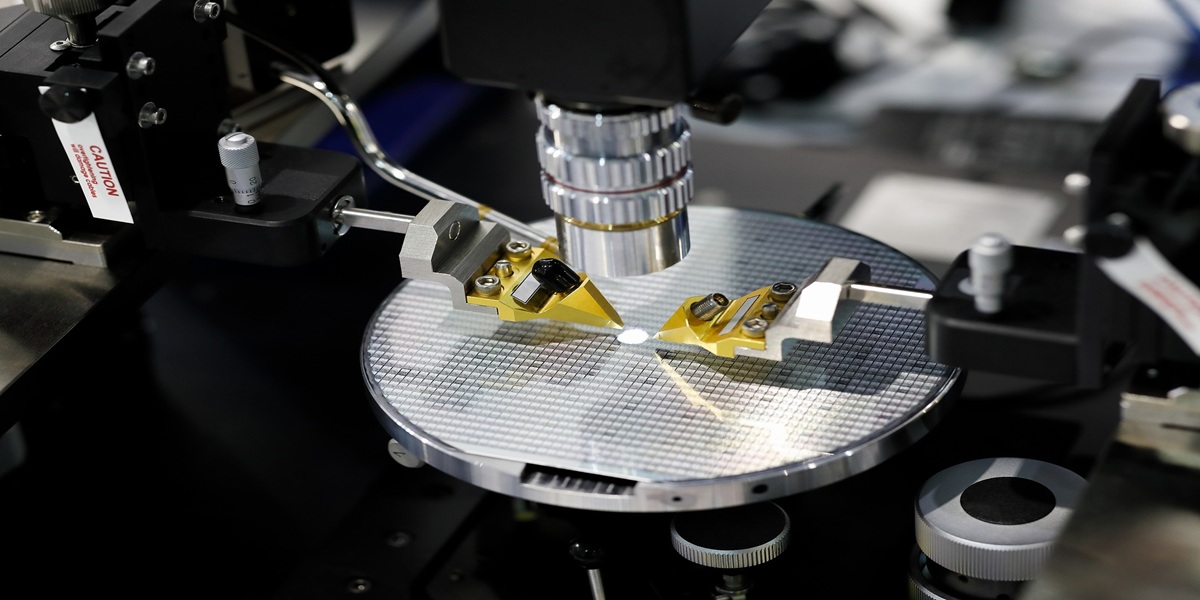

As the demand for high precision and efficiency in manufacturing continues to rise, high-speed machining technology has become a critical driving force in modern industry. In this context, the stability and precision of machinery have become crucial. Especially in high-end sectors such as aerospace, automotive manufacturing, and precision machining, even the slightest error can have significant consequences. During high-speed machining processes, machine components are subjected to extreme loads, intensifying the need for key components that ensure stable operation and enhanced machining precision.

2025-08-01 13:50:05

Founded in 1989, PARKER PLASTIC MACHINERY CO., LTD. upholds the business philosophy of “Innovative Technology, Quality First, Customer Priority,” focusing on the research, development, and manufacturing of hollow blow molding equipment. Headquartered in Wufeng, Taichung, Taiwan, PARKER has become a significant force in the domestic and international blow molding machinery sector through continuous technological investment and rich industry experience. The company has received multiple ISO 9001 and CE certifications and was honored with the Taiwan Excellence Award in 2006, demonstrating its outstanding product quality and technical strength.

2025-08-01 12:24:12

The global healthcare industry is currently undergoing a pivotal paradigm shift. Every macroeconomic trend—from demographic changes, the geopolitical reshaping of supply chains, and the convergence of biotechnology and digitalization, to the urgent demand for environmental sustainability—profoundly impacts the dynamics and trajectory of the medical device market. Against this backdrop, the medical consumables industry must not merely adapt; it must proactively lead innovation and become a key driver in building resilient healthcare defenses.

2025-08-01 13:58:10

Medical consumables are a wide range of products used by healthcare professionals on a daily basis, typically for a single use before being disposed of. Their primary purpose is to ensure patient care, maintain hygiene, and prevent the spread of infection. These items are crucial for everything from routine checkups to complex surgical procedures.

2025-08-01 13:34:35

Hot Topic

Agree