Insights

As the global manufacturing sector regains momentum following recent supply chain disruptions and economic slowdowns, multinational companies are re-evaluating where and how they source their machinery. Taiwan—once viewed as a mid-tier supplier—is now emerging as a strategic investment destination for global brands seeking high-precision CNC machining, tooling innovation, and smart manufacturing integration. With projections of double-digit growth for 2025 following a temporary downturn, Taiwan’s machine tool sector is proving its resilience and global competitiveness. As demand for automation, customization, and advanced manufacturing solutions intensifies, more international buyers are shifting their attention - and capital - toward Taiwan’s CNC and precision tooling ecosystem.

2025-05-07 10:24:20

As global industries increasingly embrace automation, digitalization, and sustainable production, Taiwan has emerged as a leader in this new wave of industrial transformation. Building on its strong foundation in traditional manufacturing—and accelerated by national initiatives like "Taiwan Industry 4.0"—Taiwanese manufacturers are rapidly upgrading their capabilities, creating exciting opportunities for both global buyers and local innovators.

2025-05-07 10:07:57

Industrial band saws are the backbone of metalworking operations. A carefully selected industrial band saw can be an invaluable asset for your manufacturing processes, offering unparalleled precision, efficiency, and versatility. This empowers you to attain superior results in applications involving heavy metal cutting. With a legacy spanning nearly four decades, WAY TRAIN specializes in designing and manufacturing heavy-duty band saws. It offers a comprehensive range of products that cater to various industrial needs, from portable bandsaws to fully automated solutions. WAY TRAIN's innovative offerings and dedication to excellence have set them apart in this highly specialized field.

2023-09-01 10:01:43

When designing a modern, functional, and stylish kitchen, choosing the right appliances is critical. PACIFIC KITCHEN APPLIANCE CO., LTD, is a leader in innovation and design of quality range hoods and boutique kitchen appliances. With a proven track record since 1975, PACIFIC offers Island Hoods, Wall Hoods, Under-Cabinet Hoods, Wine Coolers, and Inbuilt Storage Cabinets — all backed by decades of expertise, advanced manufacturing capabilities, and international certifications.

2025-04-30 14:35:27

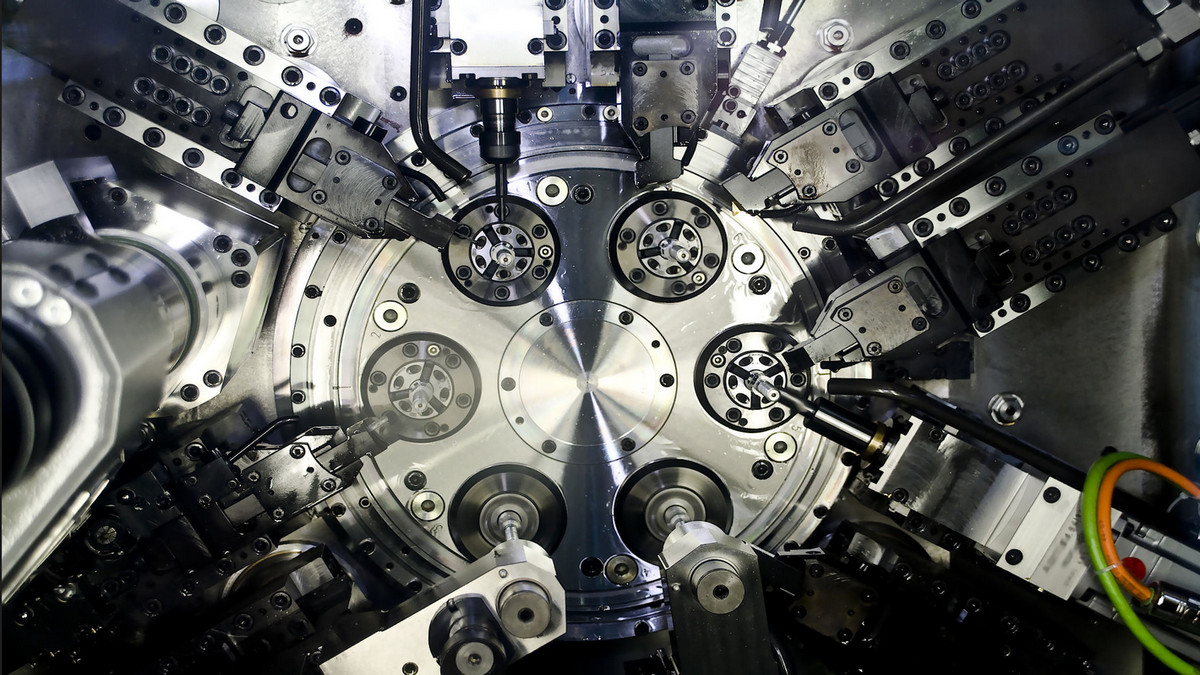

In global manufacturing, where precision, speed, and customization are essential, DMS Group Direct Manufacturer Supplier International Inc. stands as a trusted partner. Based in Taiwan, DMS Group excels in the production of high-precision CNC-turned and milled components, utilizing advanced techniques such as Swiss-type and Japan-type auto-feed bar turning, as well as offering full-scale OEM/ODM product realization services. Serving a diverse customer base across industries such as automotive, robotics, medical devices, marine components, and consumer electronics, DMS Group combines advanced manufacturing expertise with the personalized service typically associated with smaller firms.

2024-08-01 10:17:05

For over 30 years, Boarke Group has been a trusted name in the woodworking machinery industry, recognized for precision engineering, continuous innovation, and exceptional customer service. As one of the most established manufacturers of Woodworking Sanding Machines and Wood CNC Machining Centers in Taiwan, Boarke offers solutions tailored to meet the ever-evolving demands of the global woodworking market.

2025-04-29 09:57:11

Founded in 1976, Parkins Plastic Machinery has steadily grown into a global leader in the design and manufacturing of plastic bag-making machinery. With over four decades of industry expertise and a presence in over 60 countries, Parkins is the preferred partner for manufacturers seeking reliable, high-performance solutions in plastic bag production.

2025-04-25 10:45:34

Some of the most powerful innovations in fashion don’t come from high-tech labs - but from nature itself. EVOPURE+ is a visionary brand redefining sustainability by transforming agricultural byproducts into everyday essentials. Founded in 2020, the brand emerged with a simple but profound mission: to infuse sustainable practices into fashion without compromising style. Focusing on pineapple leaf fiber - an eco-friendly textile born from local agricultural waste - EVOPURE+ proves that the future of fashion can be both responsible and beautiful.

2025-04-25 10:13:32

When it comes to plumbing design - whether for residential living spaces, commercial kitchens, or luxury hotels - the importance of durable, stylish, and efficient plumbing accessories cannot be overstated. These essential components are central to convenience, sanitation, and user comfort. With a full spectrum of high-performance solutions, Byson International Co., Ltd., a leading Taiwanese manufacturer, delivers unmatched reliability and innovation in plumbing products worldwide.

2025-04-23 11:40:21

Established in 1988 and headquartered in the heart of Taiwan’s manufacturing hub, Taichung City, Chung Sing Machinery Co., Ltd., operating under the well-known brand name FORTWORTH, has earned a global reputation for excellence in the design and manufacturing of high-performance boring and milling machines. With over 30 years of engineering expertise, Chung Sing is a trusted partner for companies seeking advanced, reliable, and cost-effective machining solutions.

2025-04-23 11:15:28

Hot Topic

Agree