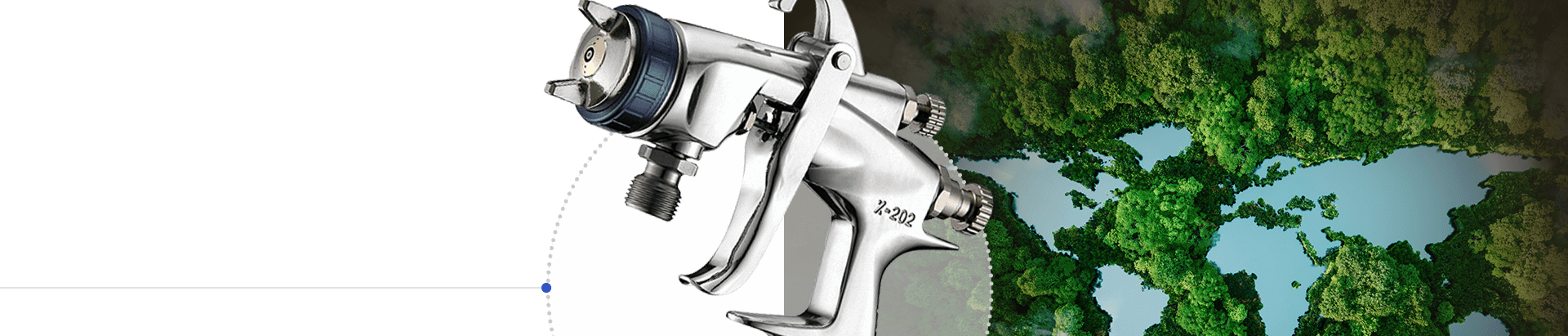

A nozzle is more than just a component; it's the heart of your production process. A poorly designed nozzle can lead to endless adjustments and maintenance headaches, while a precise and reliable one can dramatically improve your product quality, helping you stand out in the market.

Your Competitive Edge Starts with Precision Spraying

"Success is in the details. Value is created through precision." This is more than a slogan—it's the golden rule of modern industrial manufacturing. In a high-efficiency, high-demand environment, a small error at any stage can lead to significant losses. Market research indicates that the global industrial nozzle market is projected to reach $3.4 billion by 2030, a figure that reflects the growing demand for precision spraying technology across countless industries.

From the precise coatings in automotive manufacturing and the critical cooling of electronics to the hygienic cleaning in food processing, all of these operations rely on one seemingly simple yet vital component: the nozzle. An efficient and precise spraying solution not only improves product quality but also directly impacts your production efficiency and cost control.

In the pursuit of excellence, consistency and reliability are paramount. Imprecise spraying can result in product defects, wasted materials, and even disrupt an entire production line. This makes finding a stable, reliable, and customized spraying solution a common challenge for many B2B buyers and OEM/ODM project managers. This is precisely the challenge that Ranox’s expertise is built to solve.

Cultivating Taiwan, Serving the World: Ranox

With over 30 years of experience in spraying technology, Ranox has become a leading nozzle manufacturer in Taiwan. We don't just produce a wide range of nozzles; we are dedicated to providing global clients with the most professional and comprehensive spraying solutions. From R&D and design to production and testing, every step adheres to the highest standards. Through a strict Standard Operating Procedure (SOP), Ranox minimizes defect rates and offers complete after-sales service to ensure clients have peace of mind.

Ranox's products have a wide range of applications, from food processing and steel manufacturing to the precision coating of electronic components. Our spraying equipment has been well-received in the international market for years, a testament to our strength and reputation. We understand that no single standardized product can meet every unique application. That's why we have made OEM/ODM a core service, committed to creating custom solutions for our global partners to deliver unique value.

Why Choose Ranox?

- Over 30 Years of Expertise: We have accumulated deep industry knowledge and technical skills, with comprehensive quality control as the cornerstone of our business.

- Rigorous Quality Control: Our strict SOP ensures a low product defect rate, and our complete after-sales service provides our partners with a worry-free experience.

- Trusted International Reputation: Ranox's spraying equipment is highly sought after by global clients, demonstrating our solid market validation and reliable reputation.

- Exceptional OEM/ODM Capabilities: We offer flexible customization and comprehensive technical support to help clients achieve tailored spraying solutions and boost overall production efficiency.

More Than a Supplier, Your Technical Partner

A long-term partnership is built on mutual expertise and trust. Ranox is committed to providing not only high-quality nozzles but also full technical support and project collaboration. Whether you need a custom design to solve a unique spraying challenge or professional advice to optimize an existing production line, Ranox will work side-by-side with you to ensure your project's success.

If you are facing spraying challenges or are seeking a more efficient solution, Ranox looks forward to building a long-term technical partnership with you.