Since its establishment in 1984, Shang Ta Chia Industrial Co., Ltd. (STC Machinery) has focused on the design and manufacturing of plastic sheet extrusion lines, accumulating over forty years of independent R&D experience. As the global plastics industry undergoes transformation and upgrading, the company not only provides high-performance extrusion equipment but also assists clients in enhancing production capacity and efficiency with a rigorous quality control system and innovative technologies, propelling the entire industry chain toward intelligent and sustainable development.

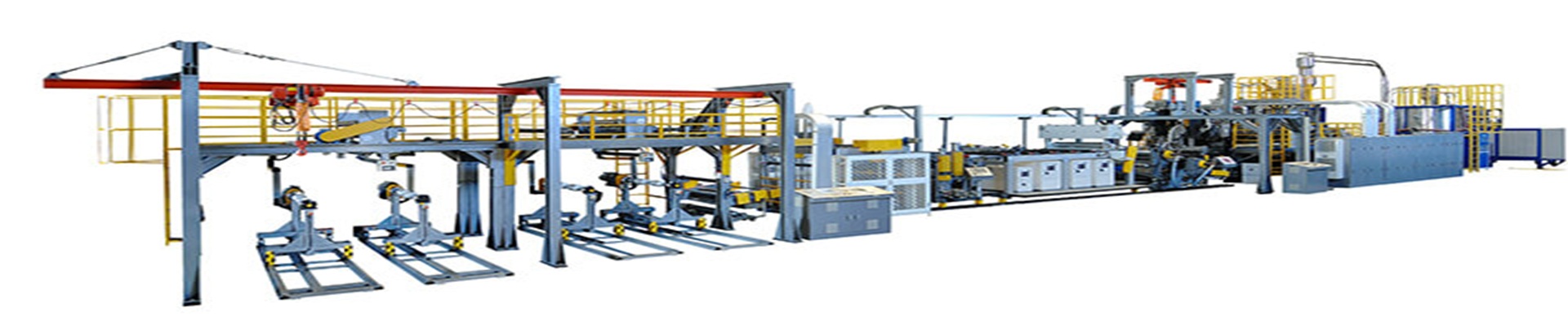

Photo by https://www.stcmach.com/e/company.html

A Solid Backer for Taiwan's Manufacturing: Four Decades of Refinement

For over four decades, Shang Ta Chia Industrial Co., Ltd. has continuously specialized in plastic sheet extrusion lines, and its product lines cover PP/PC hollow profiles, PET/PLA single-screw sheets, and PP/PC/PVC corrugated boards to serve diversified markets. With years of technical accumulation and the professional capabilities of its engineering team, the company has earned the recognition of clients both domestically and internationally, becoming a key partner in the Asian plastic extrusion equipment sector.

Precision Craftsmanship: The Extrusion Machine Standard

Shang Ta Chia offers a diverse range of products, including PP/PC hollow core sheet production lines, PET/PLA single-screw sheet extrusion lines, and PP/PC/PVC corrugated sheet production lines, to meet the production needs of various plastic products. The equipment design emphasizes high efficiency and production stability, with customized solutions provided based on client requirements. The newly launched PP hollow core sheet extrusion line features excellent structural strength and material-saving effects, helping clients effectively control costs while improving product quality.

These innovative machines, combined with the company's existing comprehensive product lines—including PMMA/ABS/PC sheet, PET sheet twin-screw, PP/PS/PE sheet, PP/3D stationery sheet, PP/PC/PVC corrugated board, PP film, melt-blown non-woven fabric, and welding rod/pelletizing extrusion lines—collectively demonstrate Shang Ta Chia's profound expertise in plastic extrusion technology, enabling clients to explore limitless product application potential.

The Quality Moat: A Path to Success

The stability and durability of equipment are key to sustained success in the plastics industry. Shang Ta Chia holds ISO 9001 certification and implements a strict quality management system, with rigorous oversight from material reception and processing to final shipment testing, ensuring every machine meets high-quality standards. This comprehensive quality control not only enhances product reliability but also secures clients' production efficiency and market competitiveness.

Continuous Innovation for a Smart, Sustainable Future

In response to the challenges of Industry 4.0 and growing environmental demands, Shang Ta Chia is actively developing intelligent control systems to enhance equipment automation and operational flexibility. It is also investing in energy-saving and material recycling production line technologies to help clients reduce energy consumption and align with green manufacturing trends. These innovative initiatives not only meet market demands but also demonstrate the company's commitment to sustainable development.

Expanding Horizons: Forging a New Chapter in the Global Market

With a profound technical foundation and an excellent reputation for quality, Shang Ta Chia is not only a leader in the Asian market but is also actively expanding global collaborations. The company will continue to focus on innovative services as its core, working with partners worldwide to advance toward higher standards and open a new chapter for the industry. To summarize, Shang Ta Chia Industrial Co., Ltd. is more than just an equipment supplier; it serves as a long-term partner in boosting client production capacity and market competitiveness. Contact Shang Ta Chia Industrial Co., Ltd. now to collaboratively create new value in plastic extrusion technology.