Since its founding in 1963, J-King International Corporation has specialized in the design and manufacturing of conveying and power transmission equipment. Under its proprietary brand JUKYO™, the company offers a diverse range of products—spanning from individual components to complete conveyor systems—providing manufacturers with one-stop solutions.

Diversified Products and Power Transmission Components

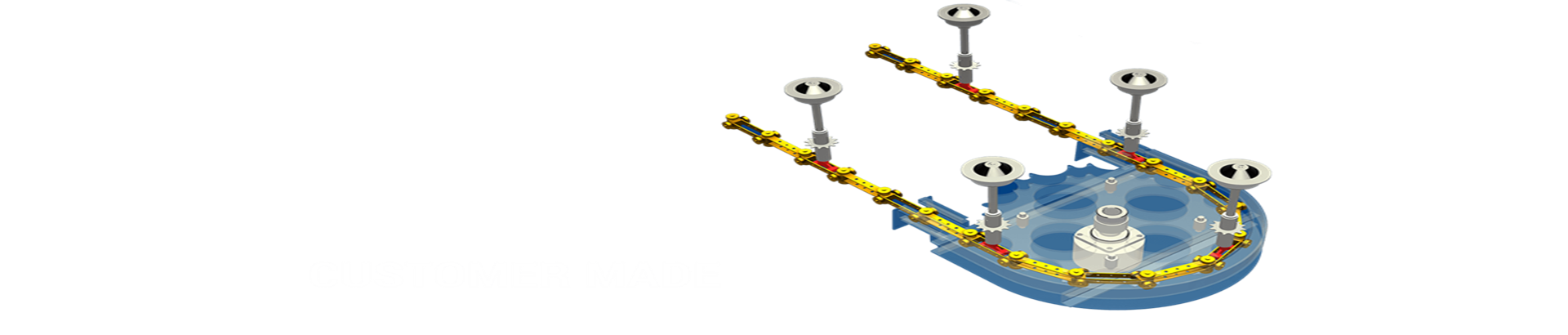

Overhead Conveyor System:

Widely applied in automotive assembly lines, electronic production, and coating equipment (such as high-capacity assembly lines and suspended transport environments), overhead conveyor systems free up valuable floor space while enhancing operational efficiency and automation. J-King not only supplies hangers and guiding mechanisms but also manufactures key components in-house, supporting full module assembly.

Floor Conveyor System:

Designed for ground-level logistics, assembly, and material handling operations, floor conveyor systems emphasize durability and stability. Typically integrating chain belts or rollers, these systems support heavy-duty, high-volume transportation needs. J-King has accumulated extensive engineering experience and supply capabilities in this field.

Roller Chains:

As fundamental components in power transmission systems, roller chains are widely used in driving and material handling applications. The JUKYO™ line includes Free Flow chains, Double Pitch chains, and F-roller chains, providing tailored configurations to meet diverse conveying demands such as load capacity and operating speed.

Power Transmission Products:

This category covers sprockets, gear reducers, and motor drive modules, delivering reliable power and speed control. J-King manufactures its own drive components and integrates them into complete system designs, demonstrating technical mastery from the component level.

Mesh Belts:

Mesh belts are designed for high-temperature, humid, or ventilated production environments, such as drying, metal treatment, glove manufacturing, and food processing. J-King provides a variety of designs, including chain-driven mesh belts and balanced mesh belts, ensuring reliable performance under demanding conditions.

Apron Conveyor Systems:

Built with robust apron chains, these conveyors are ideal for handling heavy or impact-intensive materials in industries such as metallurgy, mining, and heavy manufacturing. Known for their durability and stability, apron conveyors are critical in high-load environments.

Rollers & Accessories:

Rollers and related accessories serve as indispensable support elements in conveyor systems, including brackets and roller guides. J-King designs and manufactures these components in-house to complement its complete systems.

Custom-Made Chains:

To meet unique industrial requirements, J-King provides customized chain services, adjusting materials, dimensions, heat resistance, and other specifications. The company also supports OEM and private-label production, ensuring solutions tailored to actual application needs.

Vertical Integration: From Components to Complete Systems

J-King adopts a vertically integrated manufacturing model, covering processes such as metal stamping, roller and chain assembly, mesh belt fabrication, forging and heat treatment, motor drive production, and sprocket and gear machining—all conducted in-house.

This strategy provides strong advantages in quality control, lead-time management, and customization flexibility. Every step, from components to complete systems, is directly monitored, enabling rapid responses to market and customer demands while enhancing efficiency and reliability.

System Integration Capabilities: Complete Conveyor Solutions

Beyond supplying standalone components, J-King emphasizes system-level integration. Leveraging in-house manufacturing and design expertise, the company combines diverse product categories into complete conveyor systems suitable for production lines, logistics handling, heat treatment processes, and automated assembly environments.

These integrated systems are durable, efficient, and adaptable, with modular designs tailored to operational environments and performance requirements—forming a critical foundation for enhanced manufacturing automation.

Quality Management and Customized Service

With most production processes controlled in-house, J-King holds a natural advantage in quality assurance. From material selection and machining precision to testing procedures, consistent standards are maintained, reducing defect risks.

The company also excels in responding to customization needs. For industries with specific requirements—such as high-temperature environments, food hygiene compliance, or marine equipment—J-King develops tailored chains and drive components, ensuring products align precisely with customer applications.

Steady Manufacturing, Forward-Looking Strategy

J-King International Corporation has established a unique position in the conveying and power transmission industry through diversified products, vertical integration, and system integration capabilities. From detailed components to complete systems, the company demonstrates technical depth, professionalism, and reliability.

Looking ahead, as smart manufacturing and automation continue to accelerate, J-King is poised to expand its global presence and strengthen R&D capabilities—transforming from a traditional manufacturer into a key driver of industrial upgrades and operational efficiency.