In structural engineering projects such as bridges, high-rise buildings, and industrial facilities, the accurate cutting of H-beams and I-beams is vital for ensuring safety and structural integrity. Fabricators utilize a variety of cutting methods to meet project demands, including laser cutting, plasma cutting, water jet cutting, and large band saws.

H-Beam vs. I-Beam: Structural Insights

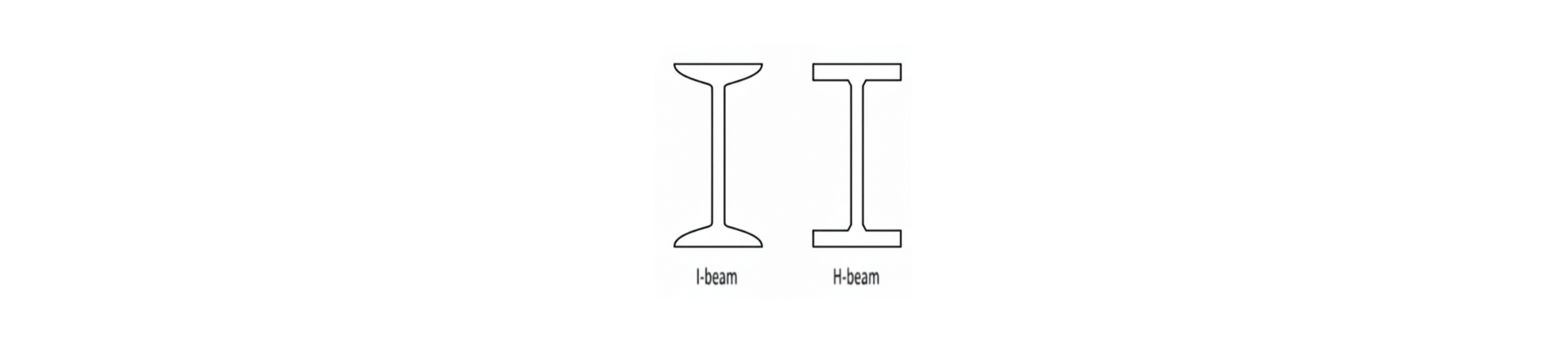

Structural steel beams come in various shapes, with H-beams and I-beams being two of the most commonly used profiles in construction projects. Understanding their structural differences is essential for selecting the right beam for specific applications.

| Feature |

H-Beam |

I-Beam |

| Flange Width |

Wide |

Narrow |

| Web Thickness |

Thick |

Moderate |

| Load Capacity |

High |

Medium |

| Typical Applications |

Bridges, heavy industrial frameworks |

Residential buildings, medium-load structures |

H-beams are characterized by their wide flanges and thick webs, which provide exceptional load-bearing capacity. This makes them particularly suitable for heavy construction projects such as bridges, large-scale industrial facilities, and high-rise building frameworks where structural integrity and the ability to support substantial loads are critical.

In contrast, I-beams have narrower flanges and moderately thick webs, offering a more material-efficient design. While their load capacity is lower than H-beams, I-beams are often preferred for projects where cost-effectiveness and ease of installation are priorities, such as residential buildings, small commercial structures, and medium-load applications.

By analyzing the specific requirements of a project, including load distribution, span length, and budget considerations, engineers can determine whether H-beams or I-beams are the optimal choice. Selecting the correct beam type ensures structural stability, safety, and efficiency throughout the construction process.

Cutting Methods and Considerations

When it comes to H-beam and I-beam cutting, selecting the right method is crucial for achieving precision, efficiency, and maintaining material integrity. Different cutting technologies offer unique advantages depending on the project requirements, material thickness, and desired finish.

Laser Cutting is widely recognized for its high precision, making it ideal for applications that demand tight tolerances and intricate designs. It works best on thin to medium steel materials and produces smooth edges that often require minimal post-processing. The controlled heat input also reduces the risk of warping, which is particularly important for structural components that must meet strict engineering specifications.

Plasma Cutting excels in speed, particularly when working with thicker metals that are difficult to process with lasers. While its precision is slightly lower than that of laser cutting, plasma cutting is highly effective for large-scale fabrication where throughput is critical. This method allows fabricators to quickly cut complex shapes and handle heavy-duty sections without compromising overall structural integrity.

Water Jet Cutting is a cold cutting technique that uses a high-pressure stream of water, sometimes mixed with abrasives, to slice through materials. Because it generates no heat, this method preserves the inherent properties of the steel, avoiding thermal distortion or metallurgical changes. While water jet cutting is slower compared to laser and plasma methods, it is particularly valuable when cutting temperature-sensitive alloys or components requiring exact material characteristics.

Band Saw Cutting provides a reliable solution for straight cuts on oversized beams or sections where uniformity is critical. Large band saw machines, such as those produced by leading manufacturers, offer low heat distortion and consistent cut quality across heavy structural beams. This method is often preferred in applications where material efficiency, operator safety, and predictable performance are prioritized.

Quick Comparison of Cutting Methods

| Method |

Precision |

Material Thickness |

Speed |

Cost Efficiency |

Ideal Application |

| Laser |

Very High |

Thin to Medium |

Moderate |

High initial, low per part |

High-precision, intricate cuts |

| Plasma |

High |

Thick metals |

High |

Moderate |

Thick metals, large-scale production |

| Water Jet |

Medium |

Variable |

Low |

Low for large volume |

Temperature-sensitive materials |

| Band Saw |

High |

Thick / Oversized |

Moderate |

Durable and low maintenance |

Straight cuts on large structural beams |

By evaluating the specific requirements of a project—such as beam size, desired cut quality, production volume, and budget—fabricators can determine which cutting method is most suitable. While laser, plasma, and water jet systems offer distinct advantages for precision or specialized applications, large band saw machines remain a reliable and versatile option for straight cuts on oversized structural steel beams. Understanding the key manufacturers in this field can help companies select the right equipment that meets both performance and operational needs.

Leading Manufacturers of Large Band Saw Machines

These companies supply band saw solutions designed for industrial-scale H-beam and I-beam cutting, integrating precision, automation, and safety features.

Enhancing Productivity and Safety in Steel Beam Cutting

Selecting the right cutting method for H-beams and I-beams depends on material thickness, precision requirements, and project scope. Large band saws are particularly advantageous for heavy structural steel applications, offering reliability, minimal thermal distortion, and efficient workflow. Industry leaders provide solutions that enhance productivity and safety in structural steel fabrication.

By understanding the strengths of each cutting method and integrating proper safety measures, fabricators can achieve high-quality results for bridges, buildings, and other structural projects.

.png)

.jpg)