Electrical Discharge Machining (EDM) is a non-traditional machining process that removes metal through electrical sparks. Unlike conventional methods, it is not limited by material hardness and can precisely create deep cavities, micro-holes, and complex structures in hardened steel, tungsten carbide, or superalloys. The three main types of EDM include wire cutting, die-sinking, and hole drilling, which are widely applied in mold making, aerospace, automotive, and medical industries. Although EDM has a slower processing speed, works only with conductive materials, and requires consideration of electrode wear and surface treatment, its advantages in high precision, zero cutting force, and superior surface finish make it an indispensable technology in precision manufacturing. Moreover, it continues to evolve in line with the trend toward smart manufacturing.

The Spark Magician: Pushing the Limits of Traditional Machining

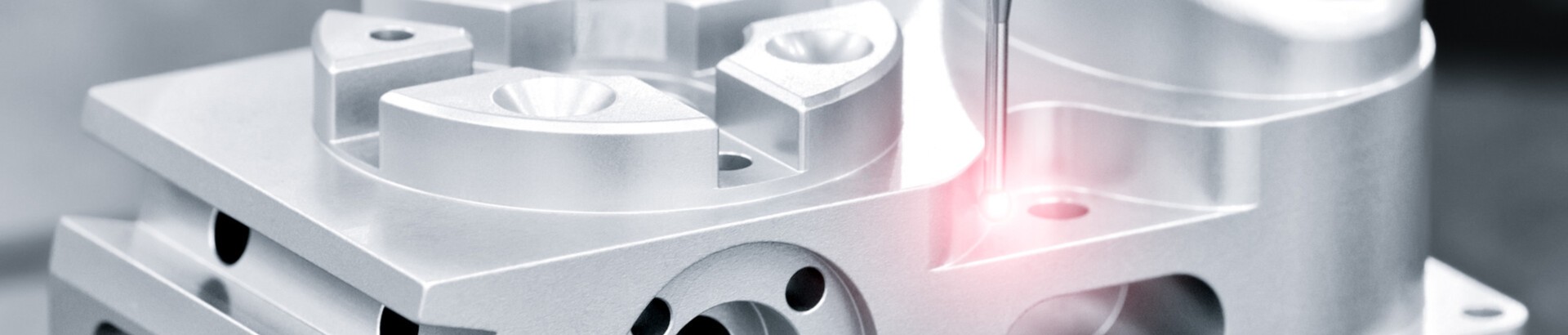

In modern manufacturing, when dealing with ultra-hard metals, micro-holes, or parts with extremely complex shapes, traditional lathes and milling machines often fall short. This is where Electrical Discharge Machining (EDM) comes in—like a “spark magician” descending from the sky, it can precisely “carve” the required contours and details on metal surfaces. Whether it’s hardened steel, tungsten carbide, or intricate microstructures in molds, EDM can gradually remove material layer by layer through tiny arcs of electrical discharge, as long as the right electrode and machining parameters are set. In other words, its principle is much like using sparks to “erode” the metal point by point until the desired shape emerges. Next, let’s take a closer look at the fundamental principles of EDM.

How Sparks Carve Metal: Unveiling the Principles of EDM

Electrical Discharge Machining (EDM) is a non-traditional machining method that does not rely on cutting tools. Instead, it uses high-frequency discharges between an electrode and the workpiece to generate localized high temperatures in an instant, melting or even vaporizing the metal surface. The molten or vaporized particles are then flushed away by the insulating dielectric fluid, gradually shaping the desired geometry.

Since the electrode never makes direct contact with the workpiece, there is no cutting force involved, meaning the part is free from additional mechanical stress. In other words, EDM works like a stream of concentrated sparks that “burn away” the metal bit by bit, removing material with micrometer-level precision while preserving the overall structural integrity. Once this core principle is understood...

The Three Master Techniques of EDM: Wire Cutting, Die-Sinking, and Micro-Drilling

Depending on different machining needs, Electrical Discharge Machining (EDM) can be divided into three main types:

- Wire-cut EDM

Using an ultra-fine metal wire (most commonly brass) as the electrode, this process works much like a “wire saw,” continuously cutting the workpiece through electrical discharges. The wire is automatically fed during machining, typically starting with rough cutting and followed by multiple finishing passes to improve accuracy and surface quality. Wire-cut EDM is especially suitable for conductive plates, enabling the production of stamping dies, precision gears, and various complex planar or profile shapes.

- Die-sinking EDM

This method requires the fabrication of a mold-shaped electrode that is the reverse of the desired workpiece geometry, often made of graphite, copper, or copper-tungsten alloys. The electrode is immersed in dielectric fluid and gradually “sculpts” the workpiece through repeated discharges, forming cavities or molds identical to the electrode shape. Die-sinking EDM is widely used in making plastic injection molds, die-casting molds, and stamping molds, and is particularly effective for deep cavities and intricate contours.

- Hole-drilling EDM

Specially designed for creating extremely small-diameter holes with relatively large depths, this technique uses slender electrodes (such as copper or graphite rods) to perform pulsed discharges while continuously feeding forward. It can produce cooling holes or jet holes ranging from tens to hundreds of micrometers. Typical applications include cooling holes in aerospace turbine blades, automotive fuel injectors, and precision fluid systems. For super-hard alloys or materials that are difficult to machine, hole-drilling EDM is often the only viable solution.

Having understood these three main techniques, we can now move on to explore the advantages and limitations of EDM to better evaluate its suitability for different applications.

Opportunities and Challenges: Why Choose EDM?

Although the material removal rate of Electrical Discharge Machining (EDM) is slower than that of conventional cutting, its unique machining mechanism allows it to achieve results that many other methods simply cannot match. Its advantages and limitations go hand in hand, requiring careful trade-offs during design and process planning.

First, EDM is almost unaffected by material hardness. Whether it’s hardened steel, tungsten carbide, titanium alloys, or nickel-based superalloys—so long as the material is conductive—it can be directly machined. EDM can even be applied after heat treatment, eliminating the need for softening or re-hardening processes. This makes it especially valuable in mold making and in the production of high-hardness components.

Second, EDM can “carve out” complex structures that conventional tools cannot easily reach. Deep cavities, sharp internal corners, and narrow grooves can be shaped layer by layer through carefully designed electrodes. This capability makes EDM an indispensable tool in manufacturing high-precision molds.

At the same time, since the electrode never makes direct contact with the workpiece, the part is subjected to virtually no mechanical stress. As a result, it does not deform or crack from vibration or cutting forces. For thin-walled structures, brittle materials, or micro components, EDM offers a remarkably safe machining method.

Combined with multiple finishing passes, EDM can reliably achieve micron-level dimensional accuracy and excellent surface quality, even approaching mirror-like finishes. These characteristics make it particularly suitable for mold cavities and precision components with stringent tolerance and surface requirements.

However, EDM also comes with notable challenges. Its material removal rate is relatively low, making it less efficient and cost-effective than milling or turning for large-scale rough machining. As such, it is best suited for precision and high-difficulty applications. Furthermore, EDM only works on conductive materials; insulators such as plastics, ceramics, and glass cannot be processed.

During machining, the electrode itself gradually wears down, requiring compensation or replacement to maintain accuracy. Otherwise, dimensional deviations may occur. In addition, the surface of the workpiece develops a recast layer from the discharges, which in some cases must be removed or polished to meet final requirements.

Finally, because EDM operates within an extremely narrow machining gap, the workpiece must be firmly clamped. Even the slightest displacement or vibration can cause shape deviations, making fixture design a critical factor.

Therefore, EDM is not a “universal solution,” but with its ability to overcome hardness limitations, create complex structures, and deliver high precision with superior surface finishes, it remains an irreplaceable technology for many of the most demanding manufacturing tasks.

Sparks Ignite Manufacturing: Applications of EDM

Electrical Discharge Machining (EDM) plays a crucial role in high-difficulty and high-precision manufacturing. The following typical applications clearly demonstrate its value:

- Mold Industry:

Plastic injection molds, stamping dies, and die-casting molds often use high-hardness steels and feature intricate internal structures. EDM has become the preferred method for manufacturing these molds, particularly for deep cavities, mirror-finish cavities, and microchannels. For example, die-sinking EDM can “carve” precise structures such as cooling channels and exhaust paths, ensuring that molds remain stable and durable under high pressure and temperature conditions.

- Aerospace Industry:

Turbine blades in aircraft engines require cooling holes with diameters of just a few hundred micrometers in highly hardened nickel-based superalloys—areas that are nearly impossible to machine with traditional cutting methods. EDM can achieve this precision without compromising material strength, allowing the blades to withstand extreme temperatures. Additionally, aerospace structural components with spiral microchannels or serrated grooves also rely on EDM for high-precision machining.

- Automotive Industry:

Modern automotive engines and transmission systems contain numerous small yet critical components. Fuel injectors require extremely fine spray holes, while turbochargers and sliding valves involve complex passages. EDM can accurately drill holes, machine fine grooves, and even restore the profiles of hardened gears or cams, helping automotive parts maintain precise dimensions and optimal performance.

- Medical Devices:

Medical instruments demand “small, precise, and delicate” machining. Implants, surgical blades, bone screws, plates, dental drills, and even heart valve components—made from stainless steel or titanium alloys—require extremely high precision and surface quality. EDM can achieve burr-free surfaces within a few micrometres, ensuring these life-critical devices meet the highest standards of safety and reliability.

The Future of Electrical Discharge Machining

Electrical Discharge Machining (EDM) is a precision manufacturing technology that “sculpts metal” using the energy of electrical sparks. Although its machining speed is slower than conventional cutting, EDM demonstrates irreplaceable advantages when working with high-hardness materials and intricate microstructures. Whether it’s hardened steel, superalloys, or extremely small deep cavities and micro-holes, EDM can achieve precise results. With no cutting forces involved, the workpiece experiences virtually no mechanical stress, making it easier to achieve high accuracy and superior surface quality.

As smart manufacturing and automation continue to advance, modern EDM machines are evolving rapidly. Features such as automatic electrode changing, robotic loading and unloading, and real-time monitoring systems enable extended “lights-out machining.” When combined with the Internet of Things (IoT) and data analytics, EDM is steadily moving toward even higher precision and efficiency.

EDM is more than just a machining process—it is a craft that integrates electrical energy, materials science, and precision engineering. As industries demand ever-higher levels of accuracy, this technology will continue to play a critical role in the future of manufacturing, pushing the boundaries of metal processing further than ever before.

.jpg)

.png)