The principle of electrical discharge machining is simply a thermal processing method that converts electrical energy into heat energy of the work piece to quickly melt the work piece.

Definition of Electrical Discharge Machining

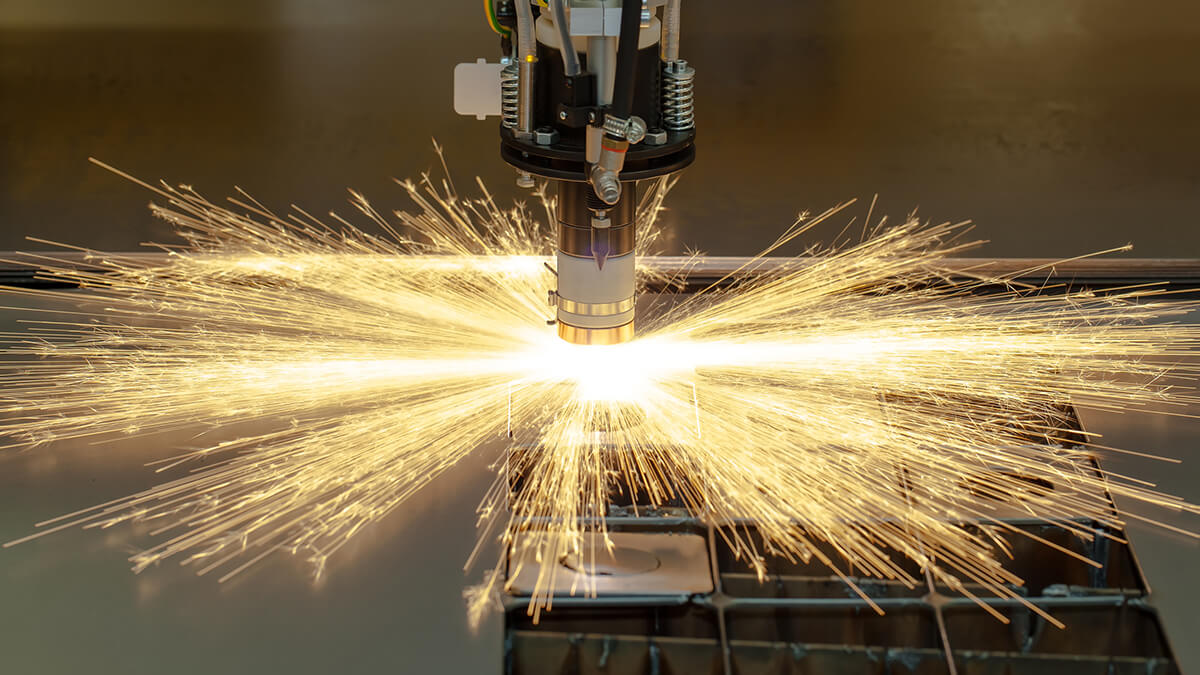

Electrical Discharge Machining (EDM) is a manufacturing process that generates sparks by discharge to make the workpiece into the desired shape. The dielectric liquid separates the two electrodes and applies a voltage to produce a rapidly and periodically changing current discharge to process the material. One of the electrodes is called a tool electrode, or pole head, and the other electrode is called a workpiece electrode, or simply a workpiece. In the process of electrical discharge machining, there will be no actual contact between the tool electrode and the workpiece electrode.

When the potential difference between the two electrodes increases, the electric field between the two electrodes also increases until the electric field strength is higher than the dielectric strength. At this time, dielectric breakdown occurs, and current flows through the two electrodes. This phenomenon is the same as the capacitor collapse, removing part of the electrode material. When the current stops, the new dielectric will flow into the electric field between the electrodes, excluding solid particles, and the insulation of the dielectric is restored. After the current flows, the potential difference between the two electrodes will return to before the dielectric breakdown, so that a new dielectric breakdown can be repeated.

Machining Process

Electric discharge machining is commonly used in mold processing: EDM and wire cutting. The electrical discharge machining referred to here mainly refers to wire cutting, although the same is an electrical discharge, the efficiency is very different.

The working principle of electrical discharge machining is: between the machine tool and the workpiece (positive and negative electrodes), a method of machining to remove excess material by electrical corrosion during electrical discharge to achieve the size and shape quality of the remaining workpiece. Take discharge as an example:

Electrode:The electrode selection material needs good conductivity, high melting point, easy processing, and corrosion-resistant materials. Common materials are copper, graphite, copper-tungsten alloy, and molybdenum. Copper and molybdenum wire are the main wire cutting materials. When processing, the electrode and the product will be corroded at the same time, but because of the characteristics of the electrode, the degree of corrosion is much smaller than the amount of erosion of the workpiece, which can be almost ignored.

Liquid Coolant:The main function of the liquid coolant is not cooling, but as a discharge medium, which plays a role in cooling and chip removal during processing. The requirements are low viscosity, high melting point, and relatively stable, non-volatile materials, common are: kerosene, deionized water, and emulsion.

After the pulse voltage is applied between the machine tool electrode and the workpiece, once there is a proper gap between the workpiece and the electrode, the current will break the medium between the workpiece and the electrode, and a connected discharge channel appears.

The discharge channel will instantly generate high temperatures, causing the surface of the workpiece to melt or even vaporize. It rapidly shrinks and explodes at the discharge gap. A small part of the surface of the workpiece is eroded and thrown out, and a huge electrical pit appears.

After the completion of one electrical discharge machining, the two electrodes will quickly return to a safe distance, relying on the dielectric to restore insulation. In this way, the surface of the workpiece is gradually eroded by the pulse voltage repeatedly acting on the workpiece and the electrode, but this process is very slow.

Electric Discharge Machine

Electrical Discharge Machine(EDM), Die-sinking EDM, also called cavity type EDM or volume EDM consists of an electrode and workpiece submerged in an insulating liquid such as more typically, oil or, less frequently, other dielectric fluids. The electrode and workpiece are connected to a suitable power supply. The power supply generates an electrical potential between the two parts. As the electrode approaches the workpiece, dielectric breakdown occurs in the fluid, forming a plasma channel, and a small spark jumps.

These sparks usually strike one at a time because it is improbable that different locations in the inter-electrode space have identical local electrical characteristics which would enable a spark to occur simultaneously in all such locations. These sparks happen in huge numbers at seemingly random locations between the electrode and the workpiece. As the base metal is eroded, and the spark gap subsequently increased, the electrode is lowered automatically by the machine so that the process can continue uninterrupted. Several hundred thousand sparks occur per second, with the actual duty cycle carefully controlled by the setup parameters. These controlling cycles are sometimes known as "on time" and "off-time." The on-time setting determines the length or duration of the spark. Hence, a longer on time produces a deeper cavity for that spark and all subsequent sparks for that cycle, creating a rougher finish on the workpiece. The reverse is true for a shorter time. Off time is the period of time that one spark is replaced by another. A longer off time, for example, allows the flushing of dielectric fluid through a nozzle to clean out the eroded debris, thereby avoiding a short circuit. These settings can be maintained in microseconds. The typical part geometry is a complex 3D shape, often with small or odd-shaped angles. Vertical, orbital, vectorial, directional, helical, conical, rotational, spin, and indexing machining cycles are also used.

Some of the advantages of EDM include machining of:

- Complex shapes that would otherwise be difficult to produce with conventional cutting tools.

- Extremely hard material to very close tolerances.

- Very small workpieces where conventional cutting tools may damage the part from excess cutting tool pressure.

- There is no direct contact between tool and workpiece. Therefore delicate sections and weak materials can be machined without any distortion.

- A good surface finish can be obtained.

- Very fine holes can be drilled.

Some of the disadvantages of EDM include:

- The slow rate of material removal.

- Potential fire hazard associated with use of combustible oil-based dielectrics.

- The additional time and cost used for creating electrodes for ram/sinker EDM.

- Specific power consumption is very high.

- Power consumption is high.

- Electrically non-conductive materials can be machined only with specific set-up of the process.

.png)