Electrical Discharge Machining (EDM) has emerged as a versatile and indispensable tool for machining challenging materials, especially exotic alloys and composites. The demand for intricate components made from materials like titanium, nickel-based alloys, and bio-compatible materials in industries such as aerospace and medicine has challenged EDM technology to evolve and adapt. Techniques tailored to meet the demands of these specific industries have enabled EDM to excel in machining such materials.

Challenges in Machining Exotic Alloys and Composites

Exotic alloys and composites, often selected for their exceptional strength, corrosion resistance, and specific mechanical properties, pose unique challenges for traditional machining processes. The valuable contributing attributes of these materials make them notoriously difficult to machine using conventional methods. Some of the challenges associated with machining exotic alloys and composites include:

Hardness: Exotic alloys, such as titanium and nickel-based alloys, are renowned for their hardness. Machining these materials requires tools that can withstand high levels of abrasion and heat without compromising precision.

Thermal Conductivity: Exotic alloys often exhibit high thermal conductivity, which can result in elevated temperatures during machining. This thermal conductivity can lead to tool wear and affect the surface finish of machined components.

Abrasiveness: Composites, which consist of a combination of materials like fibers and resins, can be abrasive. This abrasiveness poses a challenge to traditional cutting tools, leading to rapid wear and reduced tool life.

Bio-Compatibility: In the medical industry, machining bio-compatible materials, such as certain alloys and ceramics, demands precision to ensure the safety and efficacy of medical devices. Traditional machining methods may struggle to meet the stringent requirements of the medical sector.

EDM Techniques for Challenging Materials:

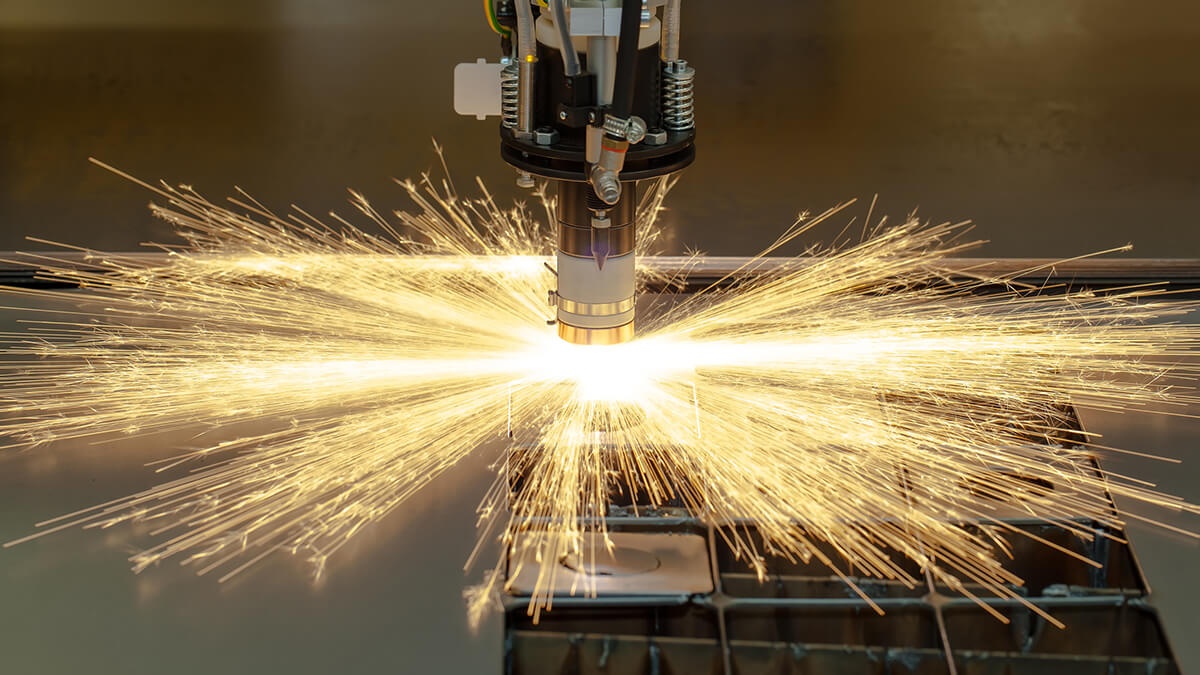

The evolution of EDM techniques has been instrumental in overcoming the challenges associated with machining exotic alloys and composites. Unlike traditional methods, EDM relies on the principle of electrical discharge to erode material, making it well-suited for hard and difficult-to-machine materials. Some key EDM techniques tailored for challenging materials include:

Wire EDM for Exotic Alloys: Wire EDM has proven highly effective in machining exotic alloys like titanium and nickel-based alloys. The process involves using a thin, electrically charged wire to create precise cuts in the workpiece. The non-contact nature of wire EDM minimizes tool wear, making it suitable for materials with high hardness.

Sinker EDM for Complex Shapes: Sinker EDM, also known as die sinking or cavity-type EDM, excels in machining complex shapes in exotic alloys and composites. This technique involves creating a cavity or recess in the workpiece by using a shaped electrode. Sinker EDM is particularly beneficial when dealing with intricate parts that may be challenging to produce using traditional methods.

EDM Drilling for Precision Holes: Machining holes with high precision in exotic alloys can be demanding. EDM drilling, which utilizes a rotating conductive tube to create holes, offers exceptional accuracy and is well-suited for materials with high hardness and thermal conductivity.

Aerospace Applications: EDM for Titanium and Nickel-Based Alloys

Titanium and nickel-based alloys, commonly used in aerospace components, present formidable challenges due to their hardness and resistance to conventional machining methods. EDM has emerged as a key technology, providing precision and efficiency in machining critical components like turbine blades and engine parts. It excels in maintaining material integrity, cutting through hardened alloys with minimal heat impact. The aerospace industry has significantly reduced production time and costs by adopting EDM for machining titanium and nickel-based alloys, ensuring intricate details without compromise.

Medical Industry Applications: Machining Bio-Compatible Materials

In the medical industry, materials such as medical-grade stainless steel, titanium, and ceramics are commonly used in the manufacturing of implants, surgical instruments, and other medical devices. EDM has found a niche in machining these bio-compatible materials.

Its non-contact machining process ensures that bio-compatible materials maintain their integrity during manufacturing. The precision and accuracy of EDM are crucial for producing intricate medical components with complex geometries, making it an ideal choice for the medical sector's intricate machining requirements, especially when working with small, delicate parts.

Innovations in Electrode Materials for Improved Material Compatibility

One of the key factors driving the success of EDM in machining challenging materials is the continuous innovation in electrode materials. The choice of electrode material significantly influences the efficiency and effectiveness of the EDM process, especially when dealing with exotic alloys and composites.

Copper-Tungsten Electrodes: Copper-tungsten electrodes have become a popular choice for EDM applications involving challenging materials. The combination of copper's electrical conductivity and tungsten's hardness results in electrodes that withstand the abrasiveness and high temperatures associated with machining exotic alloys.

Graphite Electrodes for High Precision: Graphite electrodes are favored for their ability to provide high precision in EDM processes. They are particularly effective in applications where intricate details and fine finishes are required. The use of graphite electrodes contributes to reduced tool wear and improved surface finish, critical factors when working with challenging materials.

Coated Electrodes for Extended Tool Life: Coated electrodes, such as those with diamond-like carbon (DLC) coatings, offer enhanced wear resistance. These coatings provide a protective layer that extends the tool life when machining abrasive composites and alloys, ensuring sustained efficiency and cost-effectiveness.

The increasing use of EDM in machining exotic alloys and composites has brought about a notable shift in modern manufacturing. EDM has adapted to the unique challenges posed by hard, thermally conductive, and abrasive materials through techniques like wire EDM, sinker EDM, and EDM drilling, ensuring precision and efficiency.

Industries such as aerospace and medical, which demand intricate components from these materials, prefer EDM for its ability to maintain material integrity. Ongoing innovation in electrode materials, such as copper-tungsten, enhances EDM's compatibility, promising extended tool life and improved finishes. As technology advances, EDM will continue to shape precision manufacturing in diverse industries.

.png)