When purchasing plastic recycling machinery, careful selection of equipment is important to ensure the efficiency, effectiveness, and sustainability of your recycling operations. ACERETECH is a creative company that was founded in 2015. ACERETECH focuses on providing machinery that maximizes the recovery and reuse of materials during the recycling process. Efficient material recovery systems contribute to reducing waste and conserving resources.

Comprehensive Offerings for a Greener Tomorrow

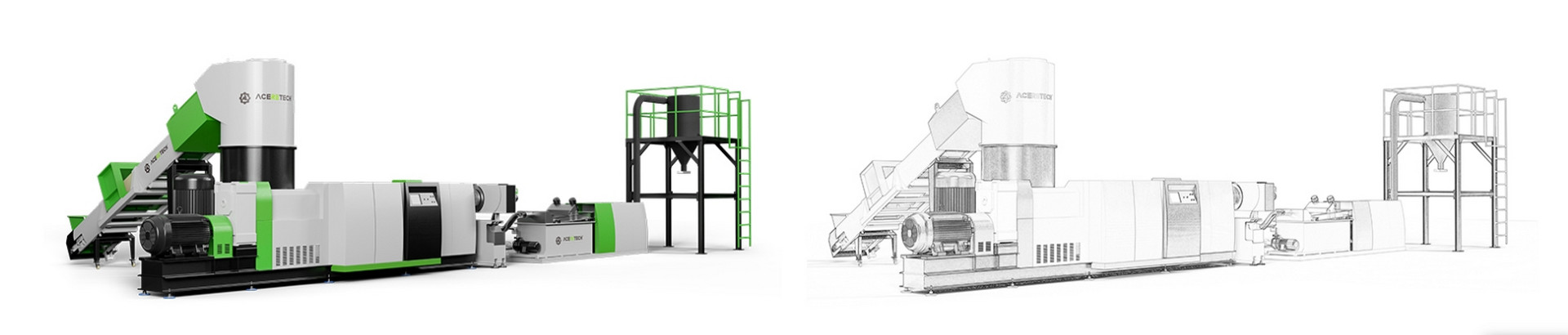

ACERETECH features a comprehensive range of offerings extending from high-capacity performance plastics agglomeration and re-granulating lines tailored for film and rigid recycling, to single screw extruder recycling pelletizing system dedicated to the recycling of rigid waste plastics. It offers various advanced plastic machinery such as cutter compactor recycling pelletizing line, twin screw extrusion machines, and much more. These advanced systems transform plastic waste into reusable pellets, providing a sustainable foundation for the creation of new products. ACERETECH also boasts sophisticated crushing, washing, and drying systems, specially designed for the pre-processing of waste and impurity plastics. This multifaceted approach ensures that the entire plastics recycling lifecycle is accounted for, from the initial stages of processing to the final creation of valuable recycled materials.

Advantages that Set ACERETECH Apart

With over two decades of experience in plastics recycling, ACERETECH’s specialized R&D team will help you determine the best equipment to meet your recycling needs. They will ensure that the machinery you choose is compatible with the types of plastics you plan to recycle. They will also help you choose machinery with an appropriate processing capacity to meet your recycling volume needs, ensuring adequate capacity and eliminating any inefficiencies that could hinder your recycling efforts. ACERETECH's high-quality machinery will reduce downtime and maintenance costs, leading to a more efficient and cost-effective recycling process. Energy-efficient equipment will not only reduce operational costs but also minimize the environmental impact of your recycling process.

ACERETECH's complete sales system, encompassing pre-sales, sales, and after-sales support, ensures a seamless experience for its customers. A professional sales team with proficiency in local languages for English, Spanish, Turkish, and Russian markets fosters effective communication and understanding, further solidifying the company's global presence.

A Vision for a Sustainable Future

ACERETECH is committed to tackling the global plastic waste crisis head-on. The company's plastic recycling technology is meticulously crafted to address the pressing issues of waste plastics regrinding, washing, and re-pelletizing. By focusing on these critical aspects, ACERETECH plays a pivotal role in diverting plastic waste from landfills and oceans, channeling it back into productive use.

ACERETECH bridges the gap between technological advancement and environmental stewardship. Their commitment to plastic recycling technology, coupled with a dedication to global partnerships, positions them at the forefront of a more sustainable future, reshaping industries and promoting a circular economy for generations to come.