Growth Potential of the Toggle Clamp Market and Good Hand Brand Positioning

- Global Toggle Clamp Market Overview

- Key Growth Drivers

- Brand Spotlight: Good Hand

- Opportunities & Strategic Insights

- Conclusion

Global Toggle Clamp Market Overview

While clamps overall represent a multibillion-dollar global market, toggle clamps form a crucial segment, particularly within industrial workholding and jig & fixture applications. Industry reports estimate that the global clamp market will continue to grow at 4%–5% CAGR through 2030, with toggle clamps benefiting from the expansion of automation and high-precision assembly lines.

Key Growth Drivers

- Industrial Automation and Smart Manufacturing – Toggle clamps with quick-action designs and safety locks are increasingly integrated into automated lines, ensuring both efficiency and operator protection.

- Precision Assembly and Workholding – The demand for stable and repeatable clamping solutions in high-precision machining drives adoption of toggle clamps across industries.

- APAC Manufacturing Expansion – Strong growth in Asian manufacturing sectors fuels rising demand for toggle clamps in woodworking, automotive, and electronic applications.

Brand Spotlight: Good Hand

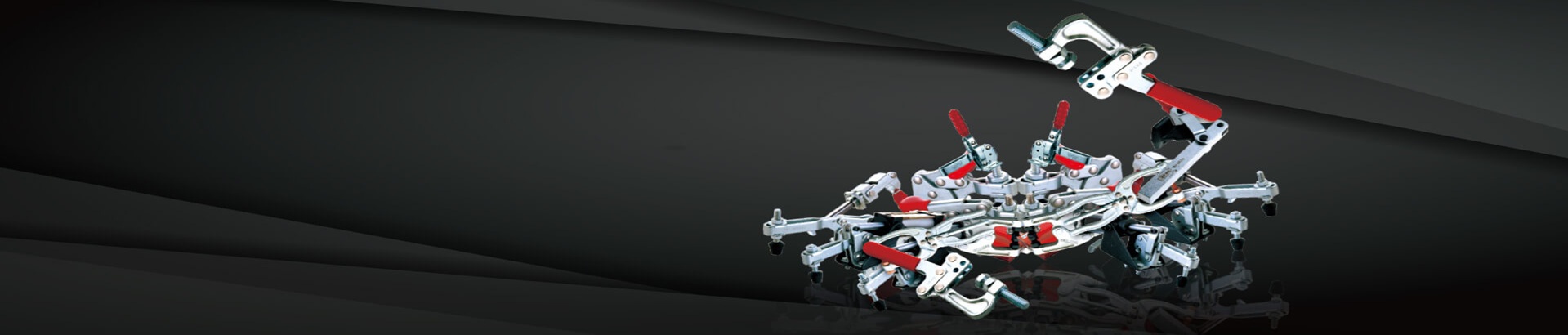

Since launching its first toggle clamp in 1974, Good Hand has served both Asian and European markets. Known for its well-engineered designs and consistent quality, the brand has steadily expanded its product line to meet global industry needs. Its product portfolio includes:

- Horizontal / Vertical Hold-Down Clamps

- Straight Line Action Clamps

- Pull Action Latch Clamps

- F-Type Toggle Clamps

- Heavy-Duty and Pneumatic Clamps

Opportunities & Strategic Insights

Expand into Heavy-Duty & Industrial Applications

- Expand in Smart Manufacturing – Leverage quick-release and modular designs to align with intelligent production systems.

- Strengthen Global Distribution – Build on existing branches in the U.S., U.K., and APAC to enhance customer support and supply chain integration.

Conclusion

Toggle clamps remain a cornerstone of industrial workholding, combining efficiency, safety, and durability to meet modern manufacturing needs. With its specialized expertise, comprehensive product portfolio, and global presence, Good Hand is uniquely positioned to strengthen its leadership in the toggle clamp market and capture opportunities in the era of smart manufacturing.