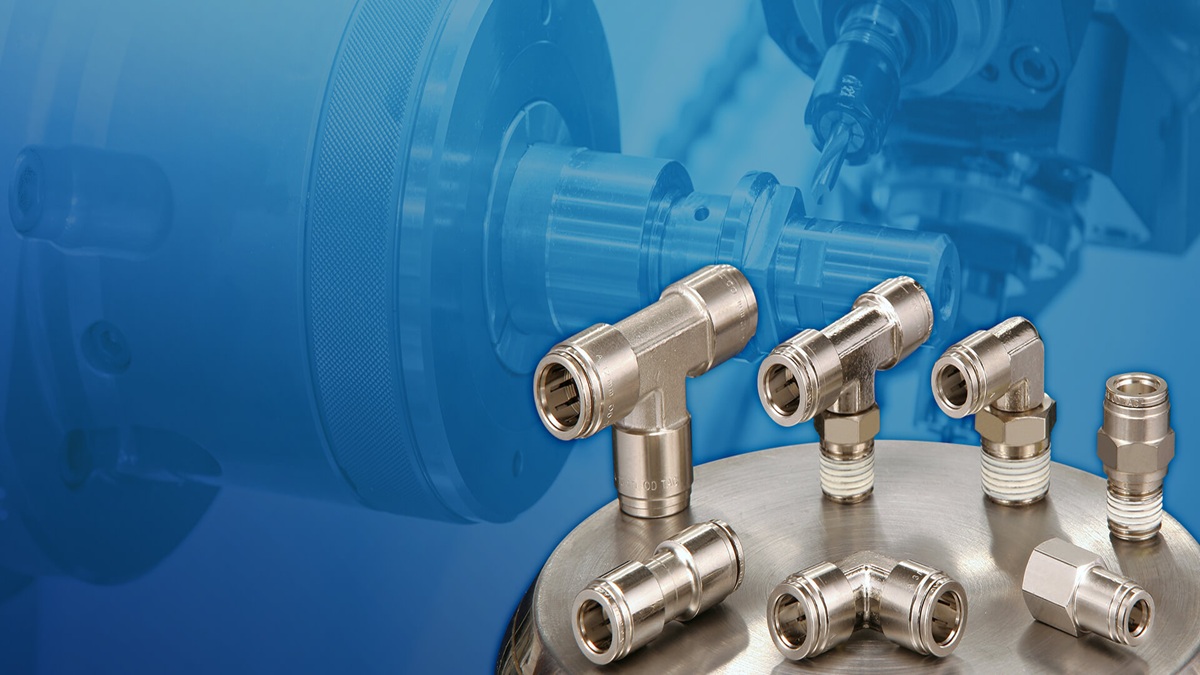

GUANG YANG Hardware: Taiwan Pneumatic & Hydraulic Fittings Manufacturer Expanding in Global Markets

The global pneumatic fittings market was valued at around USD 7.2 billion in 2024 and is projected to reach USD 11.8 billion by 2033, growing at a CAGR of 5.6%. Demand drivers include increased automation, smart manufacturing, and precision industrial controls. The broader pneumatic components market (including valves and actuators) is even larger, expected to nearly double to USD 47 billion by 2033.

Guangyang Hardware’s Growth Path

Starting with sanitary valves, GUANG YANG expanded into pneumatic and hydraulic fittings by 1986 and further diversified into welded elbows, carbon and forged steel pipe fittings by 1991. In 2004, the company established a production base in Hebei, China, enhancing manufacturing capacity and regional supply capabilities. More recently, GUANG YANG has honed expertise in DOT-certified brake fittings under its TAC brand, meeting U.S. FMVSS 571.106 safety standards. This specialization underlines its commitment to quality and regulatory compliance in the global automotive supply chain.

Competitive Advantages

GUANG YANG’s ISO 9001 certification, diverse product range, and modern warehousing and logistics systems position it as a reliable supplier for automotive, machinery, and automation industries. Its ability to meet international quality and safety requirements makes it a preferred partner for global buyers.

Market Outlook and Strategic Positioning

Rising automation, stricter safety regulations, and expanding applications for pneumatic and hydraulic systems are creating significant growth potential. GUANG YANG’s deep know-how in brake fittings and pipe connectors enables it to capitalize on growing demand across Asia-Pacific and global markets. Automation and green manufacturing trends also drive demand for precise, durable fittings. GUANG YANG’s ongoing investment in quality and certification will support its competitive edge and help capture emerging opportunities.

Conclusion

GUANG YANG Hardware stands as a prime example of a Taiwanese manufacturer successfully evolving with industry trends and global demands. By focusing on quality, compliance, and market needs, it has positioned itself for sustainable growth in the dynamic pneumatic and hydraulic fittings market. Its commitment to innovation and international standards will continue to drive its expansion in the years ahead.