As packaging lines embrace greater automation and data integration, smart labeling has become a vital component of packaging systems. While AI vision systems enhance visual inspection and quality control, smart labeling technologies help manage data, ensure compliance, enhance traceability, and enable real-time customization in the packaging process.

What is Smart Labeling?

Smart labeling refers to the use of advanced technologies—such as RFID tags, NFC chips, 2D barcodes, and automated label applicators—to embed and manage electronic data within product packaging. Unlike traditional labeling, which is static and purely visual, smart labels are dynamic and scannable. They provide real-time information about a product's identity, status, location, or condition as it moves through production and distribution.

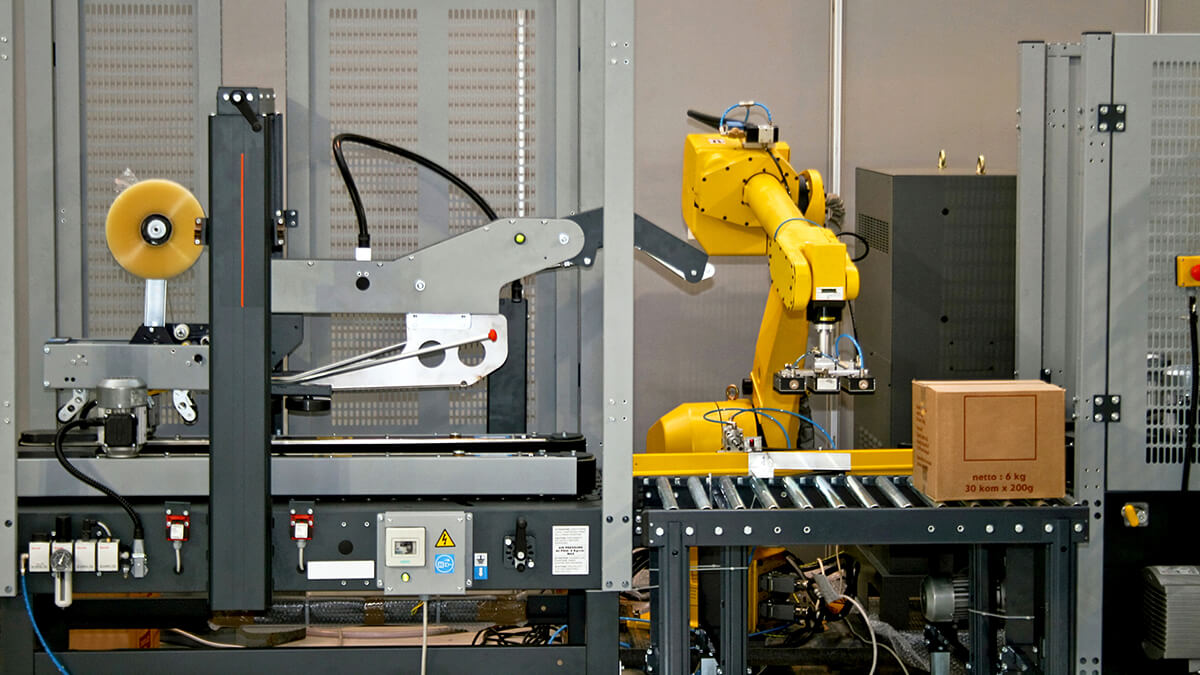

These labels are applied by intelligent labelers—automated machines that print, verify, and affix labels onto packages with precision and speed. When integrated into broader packaging systems, smart labeling enables automatic tracking, inventory management, and quality assurance with minimal human intervention.

Smart Labeling vs. AI Vision Systems

While both technologies are part of Industry 4.0, they serve distinct but complementary roles:

• AI vision systems inspect visual quality (e.g., seal integrity, print alignment, product defects).

• Smart labeling systems manage information—ensuring each package carries accurate and trackable data.

While smart labels provide data for traceability, AI vision verifies the physical integrity and accuracy of label placement. However, smart labeling also stands alone as a major enabler of efficiency and transparency across the supply chain.

Benefits of Smart Labeling in Packaging Operations

1. End-to-End Traceability

Smart labels give each product a unique digital identity. Through RFID, barcode, or QR code data, every package can be tracked in real time from the packaging station to the retail shelf. This is crucial for:

• Inventory accuracy

• Recalls and compliance

• Anti-counterfeiting efforts

• Consumer transparency (e.g., showing product origin or batch history)

For instance, pharmaceutical packaging often encodes lot numbers and expiry dates directly into 2D barcodes or RFID tags, enabling precise tracking of sensitive items and regulatory compliance.

2. Automation and Speed

Smart labeling systems automate what used to be manual and error-prone tasks:

• Reading product data (e.g., weight, batch, serial)

• Generating labels with dynamic information

• Applying them with robotic precision

• Verifying the correct label was placed via scanners or integrated AI vision

This automation boosts throughput and reduces the risk of human error, especially in high-volume sectors like food, e-commerce, or personal care products.

3. Flexible Customization

Smart labeling systems can dynamically print and apply variable information—including names, lot numbers, expiration dates, or even promotional graphics—on the fly. This flexibility is key for:

• Personalization (e.g., limited editions, custom orders)

• Batch changes (e.g., switching SKUs with no downtime)

• Multilingual or region-specific labeling

AI-enabled smart labelers can also adjust for different package sizes and shapes, allowing for seamless product changeovers with minimal operator input.

4. Real-Time Data Integration

Smart labeling systems often connect with Manufacturing Execution Systems (MES) or ERP databases. This allows seamless synchronization between production data and labeling output, ensuring accuracy and reducing waste. For example:

• A product's weight is verified, and the correct label is applied with nutritional information.

• A packaging error is detected, and the labeler halts until corrected.

Such integration supports both production accuracy and compliance.

Real-World Applications of Smart Labeling

Pharmaceuticals

Smart labels are vital in pharmaceutical manufacturing, where packages must be encoded with traceable and compliant data. Labels include lot numbers, expiry dates, and unique identifiers, often using RFID or serialized 2D barcodes. AI vision systems may assist in reading these labels to verify accuracy, but the core functionality lies in the smart label’s data structure and scannability.

E-Commerce Fulfillment

In global e-commerce warehouses, smart labeling systems scan, weigh, label, and sort packages automatically. This allows for error-free order processing and instant inventory updates—critical in high-volume environments like Amazon’s fulfillment centers.

Food and Beverage

Smart labels support compliance with allergen labeling laws and dynamic inventory tracking. A smart label system ensures the right nutritional information is applied to each box, while integrating with upstream systems to reflect real-time stock movement.

Leading Taiwanese Manufacturers in Smart Labeling

Markotec (Great John Machinery Co., Ltd.)

One of Taiwan’s earliest pioneers in labeling machines, Markotec builds robust, high-speed labeling systems used across industries. Their machines feature high-precision label applicators that can integrate with smart sensors and vision modules for verification. They are a trusted supplier for brands worldwide.

Techman Robot

While best known for its collaborative robots, Techman also integrates smart labeling functions through built-in AI vision and barcode readers. A single cobot arm can identify a product, retrieve the correct label from a database, and apply it in real time, making it ideal for mid-size manufacturers.

Solomon Technology

Solomon provides advanced OCR and vision capabilities for reading and verifying labels—ensuring that data, such as serial codes, is machine-readable. Their deep-learning-driven software integrates well with industrial labelers, especially in sectors requiring ultra-high precision.

As Taiwan continues to innovate in both hardware and smart automation software, companies like Markotec, Techman Robot, and Solomon are shaping the global future of smart labeling.

.jpg)

.jpg)