Over the past decade, cutting fluid recycling and regeneration technologies have evolved from auxiliary support services into essential core equipment and processes within manufacturing. Recycling and reusing cutting fluids reduce raw material and water waste, making production processes more aligned with circular economy principles. According to market forecasts, the global cutting fluid market size will reach USD 3.78 billion in 2024 and is expected to grow to USD 5.64 billion by 2033, with a compound annual growth rate (CAGR) of approximately 4.3%. Among this, the market for regeneration equipment and treatment services is expanding particularly rapidly, reaching about USD 1.31 billion in 2024 and projected to double to USD 2.61 billion by 2033, with a CAGR as high as 7.8%.

Integration of Intelligent Control and Automatic Replenishment

The model of smart factories demands real-time monitoring of liquid concentration, automatic water replenishment, pH control, and remote sensing capabilities. Therefore, liquid management is no longer a supplementary process but a key reform ushering in the AI era, becoming an industry-standard feature. Market research indicates that liquid monitoring and AI analytics technologies — including nanosensors, data analytics, and advanced fluid analysis tools — are rapidly being adopted. This shift transforms the recycling and regeneration process from passive monitoring to active management, driving more efficient and sustainable process upgrades.

A Green Circular Economy Perspective

Traditionally, many machining sites have used oil-based or semi-synthetic cutting fluids without recycling systems, resulting in large volumes of waste discharge, resource wastage, increased health risks, and rising operational costs. Today, the industry is shifting toward bio-based and water-based fluids while adopting high-efficiency regeneration equipment. Through closed-loop systems, the service life of cutting fluids is extended, environmental impact is reduced, and the industry aligns with ESG trends and international environmental regulations.

Regional Industrial Upgrades and the Asian Market Boom

Precision Interception and Particle Separation Technologies

Faced with increasingly stringent industrial tolerances and part accuracy standards, removing contaminants with particle sizes ≥ 5 µm, or even smaller, has become a critical task in managing machining fluids. Magnetic and centrifugal separation technologies have rapidly gained popularity. The magnetic filter market exceeded USD 1.2 billion in 2024 and is expected to double to USD 2.5 billion by 2033, with a compound annual growth rate (CAGR) of 9.2%.

Extending Fluid Life and Reducing Maintenance Costs

Systems equipped with advanced filtration and particle separation technologies can effectively extend cutting fluid service life by 2 to 5 times or more. This significantly reduces replacement frequency and procurement costs, while simultaneously lowering treatment expenses. Additionally, these systems inhibit bacterial growth and grease contamination, greatly enhancing overall maintenance efficiency.

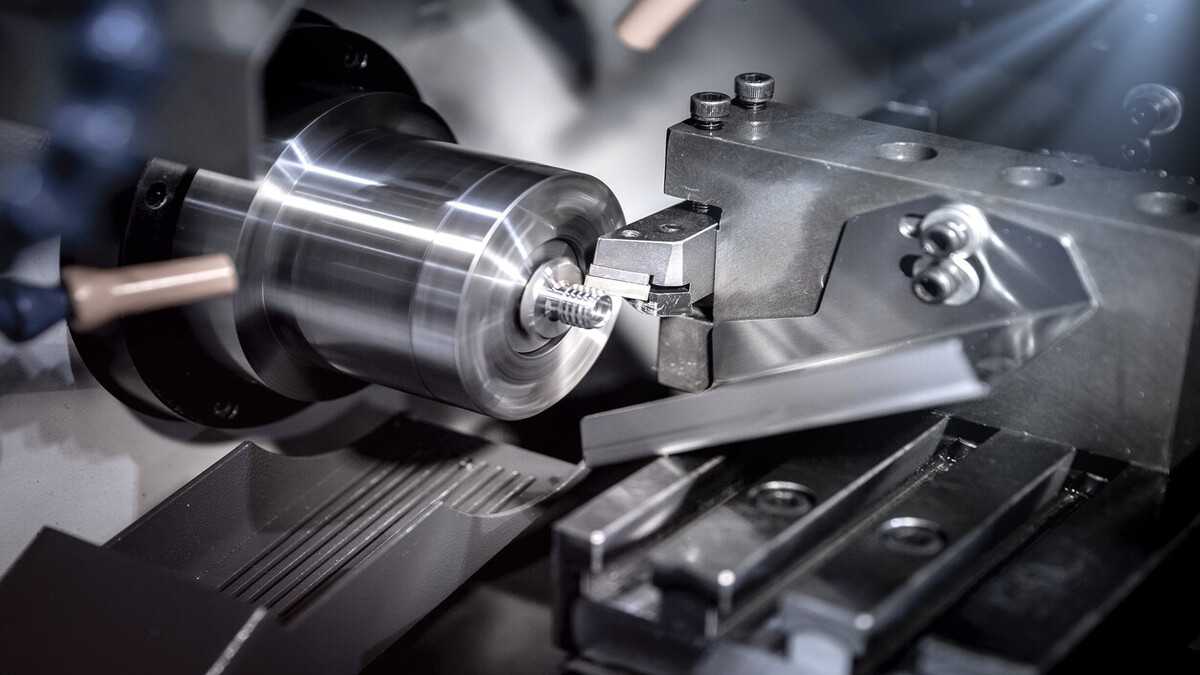

Technological Advances in Precision Machining

Asia, particularly China, India, and Southeast Asia, is rapidly becoming the most active region globally in cutting fluid consumption and the adoption of regeneration technologies. The Asia-Pacific market accounts for approximately 1.6 million kiloliters of global cutting fluid usage. Although environmental regulations are still evolving across these regions, the strong demand for industrial automation and smart manufacturing has driven the rapid adoption of recycling equipment and monitoring technologies, positioning this region at the forefront of liquid management innovation.

Conclusion

Cutting fluid regeneration technology is evolving from a supplementary tool into an indispensable core mechanism within manufacturing processes, fully addressing demands for environmental protection, health, safety, cost control, and quality improvement. With ongoing advancements in smart sensing, automation integration, and high-precision filtration systems, along with supportive policies, the industry is accelerating toward a new manufacturing norm characterized by greater sustainability, optimized efficiency, and superior quality.

.jpg)