Established in 2002 in Taichung, Taiwan, Funet Technology Inc. has emerged as a leading provider in the Electronic Manufacturing Services (EMS) sector. Specializing in Original Design Manufacturing (ODM) and Original Equipment Manufacturing (OEM) for medical, industrial, and consumer electronics, Funet holds ISO-9001, ISO-13485, and ISO-14001 certifications, forging a reputation for excellence in high-quality, innovative manufacturing solutions.

Advanced Manufacturing Capabilities

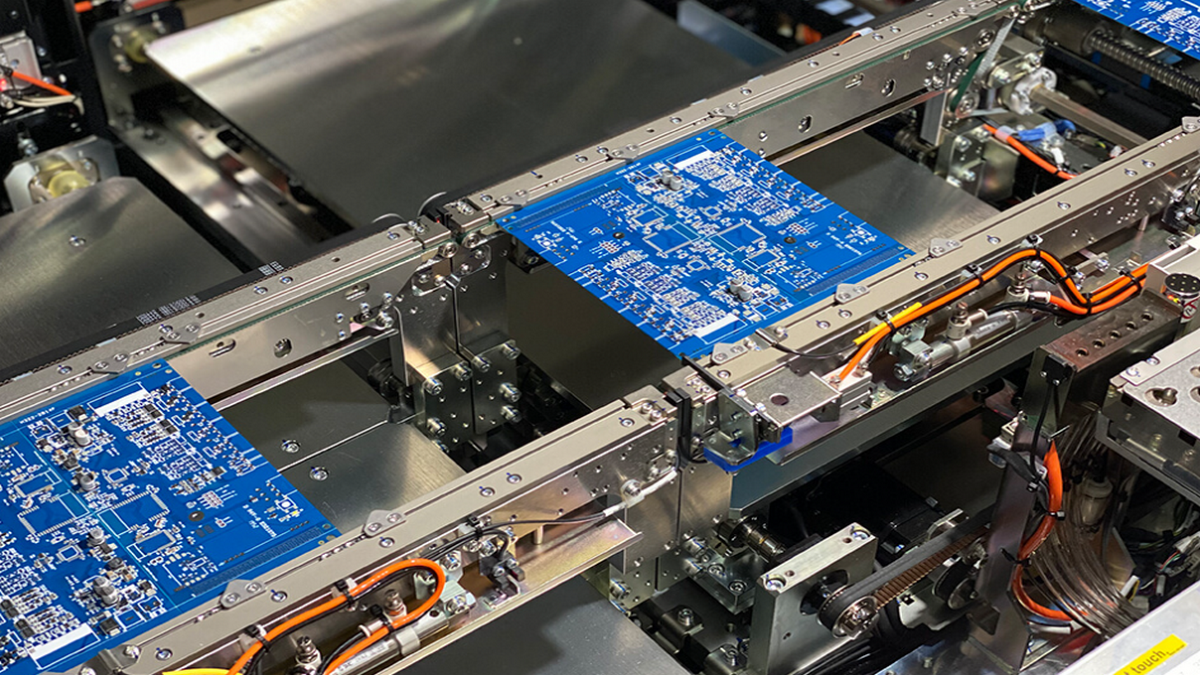

Funet’s Electronic Manufacturing Services are among the most advanced in the industry. The company upgraded its production lines in 2020 to include advanced SMT (Surface Mount Technology) and DIP (Dual In-line Package) systems, keeping pace with the latest technological advancements. Their facilities are equipped with state-of-the-art equipment for Thru-hole, Soldering, Assembly, Testing, Burn-in, and Packaging, supported by a professional team with decades of experience in manufacturing.

Surface Mount Technology (SMT)

Surface Mount Technology is a method used for producing electronic circuits in which the components are mounted directly onto the surface of printed circuit boards (PCBs). Unlike older techniques where components had leads that were inserted into holes on the circuit board, SMT components are placed on the PCB's surface and soldered in place.

This technology allows for more components to be mounted on both sides of the PCB and has many advantages over the traditional through-hole soldering technique, including:

Miniaturization: SMT enables smaller components and denser packing, which is crucial for modern electronic devices that require lightweight and compact designs.

Automation: The process is highly automated, reducing labor costs and increasing production rates.

Performance: SMT often results in better performance of electronic devices due to lower resistance and inductance at the connection points.

Cost-effective: While the initial setup can be expensive, the actual production costs are generally lower due to the high level of automation and the reduced use of materials.

SMT is widely used in the manufacturing of almost all modern electronic equipment, including smartphones, computers, and televisions.

A Dual In-line Package (DIP)

A Dual In-line Package is a type of electronic component package that has two parallel rows of electrical connecting pins. The package is usually rectangular in shape, and the pins protrude from the longer sides, making it look like a small chip with two lines of legs. This configuration is often used for integrated circuits (ICs) and some other components like switches and connectors.

DIPs are designed to be mounted on a printed circuit board (PCB) either by through-hole soldering (where the pins go through holes in the PCB and are soldered to the opposite side) or in sockets that allow the device to be removed or replaced without desoldering.

The relatively large size and robustness of DIP pins make them easier to handle and solder compared to surface-mount components so they can be used in a wide range of applications. DIP components are generally cheaper to produce and use in low-density applications compared to advanced surface-mount technologies.

Despite the rise of SMTs, DIPs are still used, especially in educational and prototyping environments where manual assembly and adjustments are common.

Comprehensive ODM and OEM Solutions

Funet Technology Inc. is a full-spectrum solution provider with extensive experience across vital sectors including medical devices, consumer electronics, and industrial components. Their commitment to advanced R&D and quality control is evident in their efficient and flexible production lines. Since 2008, Funet has collaborated with U.S. bedding manufacturers to develop electric adjustable beds, demonstrating their ability to adapt and innovate to meet every client’s unique requirements with precision and efficiency.

Strategic Location and Global Reach

Located in Taichung, Taiwan, Funet Technology Inc. benefits from Taiwan's high standards of manufacturing quality and innovation. Taiwan’s strategic location offers logistical advantages for global shipping, particularly to major markets like North America, ensuring faster turnaround times and reduced transportation costs.

Importance of ODM and OEM in Various Industries

Medical Electronics

In the medical field, where the accuracy and dependability of devices can directly impact patient care, ODM and OEM services provide the necessary precision and adherence to stringent quality controls and regulatory standards.

Industrial Electronics

For the industrial sector, these services enable the production of robust and durable electronics that can withstand harsh environments while maintaining functionality and safety.

Consumer Electronics

In consumer electronics, electronic control boards are used to manage power, speed, safety features, sensors, diagnostics, maintenance, and other control functions. Inputs from the user interface and various sensors are integrated, allowing users to start, stop, adjust speed, and control other machine functions. The control board regulates the power supply to the machine’s motor based on user settings and feedback from the system. It ensures that the motor receives the correct voltage and current to operate efficiently under varying load conditions, such as different speeds or loads.

In conclusion, Funet Technology Inc. embodies the best of Taiwanese manufacturing. Whether it's developing a new medical device, an industrial application, or a consumer electronics product, Funet's comprehensive services, strategic location, and commitment to quality make it your ideal partner for reliable, innovative, and high-quality Electronic Manufacturing Services (EMS) solutions.