As electronic components become increasingly miniaturized and high-density, the Dicing Saw has evolved from a traditional back-end processing tool into a core component of the electronic manufacturing process. Whether for wafers, sensors, MLCCs, LEDs, or MEMS devices, the dicing saw carries the critical mission of the “final cut”—requiring not only precision but also stability and speed, ensuring both component integrity and production efficiency.

Photo by https://www.pexels.com/zh-tw/photo/6755079/

Why Has the Dicing Saw Become a Core Manufacturing Tool?

Miniaturization Driving High Precision

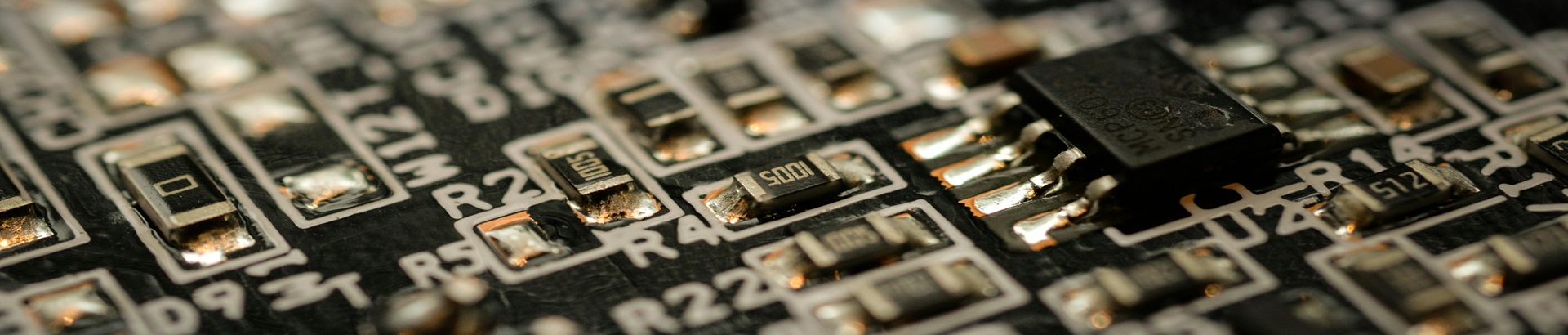

Modern electronic components are shrinking in size, demanding cutting precision at the micrometer or even nanometer level. Traditional cutting methods can no longer meet the requirements of wafer-level packaging (WLP) or ultra-thin chips.

Multi-Material Processing Capability

Dicing saws can handle a wide range of materials, including silicon wafers, ceramic substrates, glass, sapphire, and composite materials. They are applicable to various component manufacturing processes, such as MLCCs, LEDs, power devices, and sensors.

High Yield and Low Material Loss

By employing water-cooled cutting and precision control systems, dicing saws minimize cracks and edge chipping, improving component yield while reducing material waste and production costs.

Automation and Smart Manufacturing Integration

Dicing saws can be integrated with AOI inspection, robotic arms, and MES systems, enabling fully automated cutting workflows. They have become a critical processing node in smart factories.

Typical Applications of Dicing Saws

In electronic component manufacturing, dicing saws play a pivotal role. For wafers, they can cut at high speed and precision into individual dies, ensuring each die remains intact. For MLCC ceramic capacitors, dicing saws prevent edge chipping, enhancing yield and reliability. The separation of LED sapphire substrates relies on their fine cutting ability to maintain optical quality. For MEMS devices, dicing saws safely isolate microstructures, preserving component integrity. In sensor module production, they provide precise cuts for packaged modules and can handle a variety of materials efficiently.

Technological Evolution and Future Trends

High-Performance Cutting Technology

Combining laser assistance with advanced mechanical systems reduces cutting time while maintaining precision, boosting production efficiency.

Enhanced Material Adaptability

With ultrasonic cutting, low-stress processing, and specialized blades, dicing saws can handle brittle, ultra-thin, or composite materials while minimizing breakage.

Intelligent Parameter Control

AI and automated algorithms optimize cutting paths and speeds based on component shape, size, and material characteristics, enabling process optimization.

AI and automated algorithms optimize cutting paths and speeds based on component shape, size, and material characteristics, enabling process optimization.

Dicing saws can be integrated with automated inspection, robotic arms, and MES systems, while meeting cleanroom and contamination control requirements, supporting full smart factory workflows.

Conclusion

The dicing saw is more than just a cutting tool—it represents the final quality assurance step in electronic component manufacturing and a key node in smart production. As components continue to miniaturize, diversify, and demand higher reliability, the role of the dicing saw becomes increasingly critical, establishing it as an indispensable tool in the electronics industry.

.jpg)