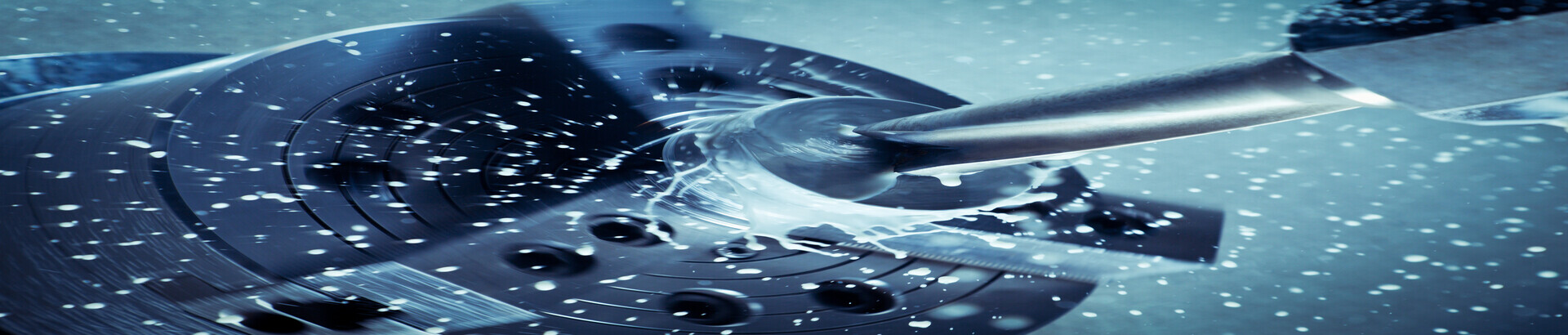

In industrial machining processes, the generation of oil smoke and fine oil mist is unavoidable. Without effective collection and filtration, these airborne contaminants pose serious health risks to workers, increasing the likelihood of respiratory diseases and occupational illnesses. At the same time, accumulated oil smoke not only pollutes the work environment and degrades air quality but also accelerates wear and malfunction of machinery, resulting in higher maintenance costs. Furthermore, the presence of flammable oil mist increases the risk of fire hazards, endangering factory safety. To ensure stable, safe production that complies with regulations, oil smoke collection systems have become an essential protective measure in modern smart manufacturing—safeguarding employee health while enhancing equipment efficiency and environmental quality.

Why Is Oil Mist Filtration Important?

In today’s industrial production environments, oil smoke and mist are common byproducts of many machining processes. If not properly collected and purified, these microscopic oil droplets and pollutants suspended in the air seriously degrade workplace air quality.

Risks and Hazards Without Oil Smoke Collection Systems:

Threats to Employee Health

Prolonged exposure to oil mist can cause respiratory illnesses, skin allergies, and other chronic health issues. Harmful substances within the mist can be inhaled deeply into the lungs, increasing the risk of occupational diseases.

Worsening Workplace Pollution

Oil mist accumulates in the air, reducing visibility and contaminating equipment and surrounding areas. This can create slipping hazards and other safety risks, negatively impacting overall workplace safety.

Reduced Equipment Lifespan and Increased Maintenance

Oil mist adheres to mechanical parts and electronic components, causing performance degradation, accelerating wear, raising failure rates, and increasing repair costs.

Increased Fire Safety Risks

High concentrations of airborne oil mist are highly flammable and pose fire hazards. Without proper control, severe industrial accidents could occur.

Decreased Production Efficiency

A polluted work environment lowers operator efficiency and product quality. Frequent equipment failures lead to production line downtime, reducing overall output.

Therefore, installing oil smoke collection systems is a critical measure to ensure factory safety, comply with environmental regulations, and maintain production efficiency. Such systems effectively filter and recover oil mist, purify workplace air, protect worker health, extend equipment life, and reduce production and maintenance costs—making them indispensable environmental safety devices in modern smart manufacturing.

Applications Across Industries

Machining Factories: Processes such as metal cutting, grinding, and drilling generate significant oil mist and metal dust containing harmful chemicals and ultra-fine particles. The dispersed mist adheres to equipment surfaces and electronic components, increasing machine failure rates and maintenance expenses, severely affecting factory productivity and safety. Additionally, oil mist’s flammability poses fire hazards if not properly managed.

Electrical Discharge Machining (EDM) Factories:

High-speed sparks between workpieces and electrodes combined with high temperatures produce abundant oil mist and smoke. This mist mainly originates from atomized and evaporated cutting or dielectric fluids under intense thermal impact, forming tiny droplets and vapor particles that severely degrade air quality. The mist deposits on equipment surfaces, causing corrosion and malfunctions, and its flammability presents fire and explosion risks.

Stamping Factories:

Cold stamping, forming, casting, and metal sheet cutting generate large amounts of steam and oil mist. These droplets and vapors arise from machining fluids vaporizing under mechanical impact and high heat, containing various harmful chemicals.

Food Processing Factories:

Maintaining a clean and safe working environment is crucial for food quality and worker health. Processing often generates significant oil mist, moisture, and fine suspended particles.

Textile Factories:

Lubricants and coolants produce substantial oil and water mist containing harmful chemicals. Without effective collection and filtration, pollution occurs, affecting textile product quality by causing color variations and oil stains, reducing product value.

Electronics Factories (Cleanrooms):

Cleanrooms require strict control of temperature, humidity, vibration, noise, and suspended particulates. Oil mist and particle contamination are especially critical. Coupled with HEPA-level filtration technologies common in cleanrooms, maintaining clean air prevents contamination spread and ensures process stability.

Conclusion

Oil mist filtration systems play a vital role across industries, serving as core devices that ensure employee health, safe production, and environmental sustainability. With the tightening of smart manufacturing requirements and environmental regulations, enterprises are actively adopting high-efficiency oil mist filtration and recovery technologies. These not only reduce health risks and protect product and equipment quality but also meet regulatory compliance, lower carbon emissions, and drive industries toward greener, more sustainable manufacturing.

Effective oil mist management is a foundational element for modern factories seeking enhanced competitiveness and transitioning toward intelligent, eco-friendly operations. It will continue to be an indispensable standard for industrial safety and environmental protection.

.jpg)