Knowledge

With rapid technological progress and increasingly diverse market demands, traditional printing techniques are no longer sufficient to meet modern industry’s requirements for precision, efficiency, and sustainability. As a result, emerging technologies such as UV printing, 3D printing, and Nanoimprint Lithography (NIL) have risen to prominence, offering solutions with higher precision, broader applications, and lower production costs. These innovations have already demonstrated value across packaging, advertising, healthcare, semiconductors, and construction. In the following sections, we will explore their technical features and real-world applications, highlighting the advantages and future potential of these cutting-edge printing technologies.

2025-08-26 14:53:26

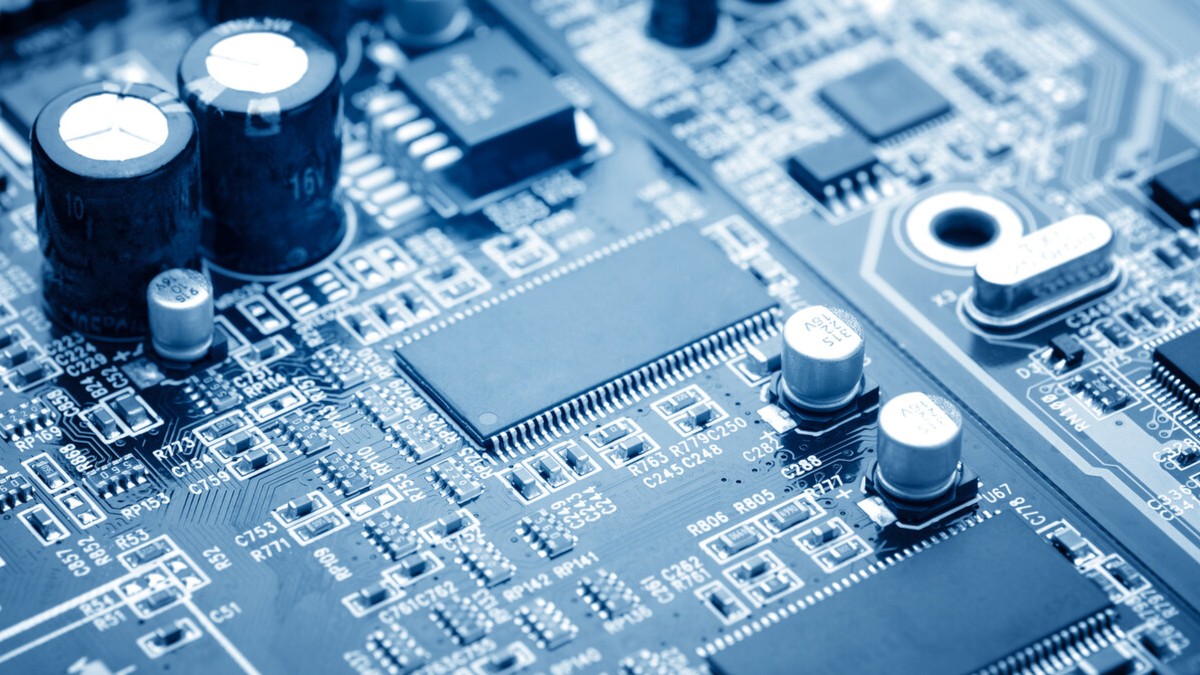

In high-risk fields such as medical, aerospace, and automotive, IPC classifications determine PCB reliability and safety. Class 3 represents the highest standard, requiring zero tolerance for defects, complete via filling, adequate copper annular rings, and rigorous inspections to ensure operation under extreme conditions, while Class 2 suits long-term use in non-critical equipment with minor cosmetic flaws allowed. Class 3’s strict criteria cover component placement, soldering, plating thickness, and environmental testing—adding cost and production time, but far outweighing the risks of failure in life- or safety-critical systems. Thus, defining high-risk equipment as Class 3 during design is essential, making IPC classification a core safeguard rather than an option.

2025-08-26 14:26:09

In the printing industry, color has always been a core element influencing both quality and sensory experience. Whether in packaging, advertising, or publications, color accuracy directly affects consumer perception and trust in a brand. With the rise of digitalization and globalization, companies increasingly demand brand consistency, making color management more than just an aesthetic concern—it is a safeguard for printing quality and brand value. This article explores the importance of color management, the application of ICC color calibration, and Pantone’s role in brand identity, providing a comprehensive overview of the core knowledge and practical value of color management in printing.

2025-08-26 12:25:50

Imagine a typical morning, a warm drink in your hands, held in what looks like an eco-friendly paper cup. You think to yourself, "At least it's not plastic. It must be better for the environment." But have you ever wondered how that paper container holds a hot liquid without leaking? Can it really be recycled with ease? The truth is, there are hidden secrets about packaging materials you may not know.

2025-08-26 11:40:53

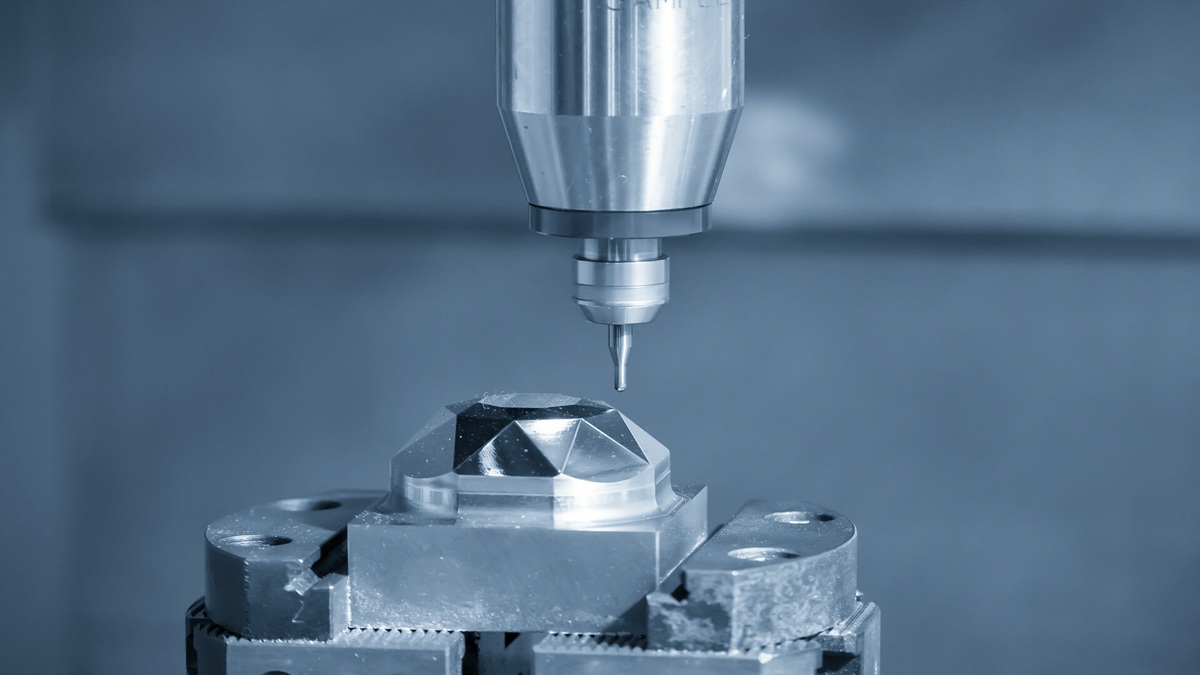

The aerospace industry demands extremely high standards for component precision, lightweight design, and durability, and CNC (Computer Numerical Control) technology is a key enabler to meet these requirements. It is widely used in the production of critical parts such as turbine blades, airframe structures, and landing gear. With the global aerospace market expected to grow from USD 900 billion in 2023 to USD 1.2 trillion by 2030 (CAGR ~4.2%), CNC technology, with its micron-level precision and automation capabilities, not only helps improve aircraft fuel efficiency by around 10% but also ensures all components comply with the stringent AS9100D certification standards, making flight safer and more reliable.

2025-08-26 10:06:19

Have you ever wondered why smartphones are becoming increasingly thinner? Driven by user convenience and portability, devices are shrinking while still retaining the functionality of previous generations, or even upgrading it, all while becoming lighter and slimmer. The key behind this lies in CNC (Computer Numerical Control) machine technology, which plays a central role in consumer electronics manufacturing. The consumer electronics industry encompasses smartphones, laptops, wearable devices (such as smartwatches), and various household appliances. These products demand extremely high standards for aesthetic design, structural precision, and functional performance. CNC technology is primarily applied in precision component machining, casing production, thermal management components, and customized designs.

2025-08-26 09:54:45

Traditionally, a car window’s main function is to shield occupants from wind and rain. Today, however, modern automotive windows have evolved to incorporate multiple convenience and safety features. High-end vehicles often feature acoustic glass, which uses multi-layer structures with sound-dampening films to effectively block wind and road noise, allowing passengers to enjoy a quiet cabin even at high speeds. Meanwhile, tempered glass undergoes specialized manufacturing processes to ensure that, upon impact, it shatters into small, uniform pieces, reducing the risk of injury and complying with the latest safety regulations. This integration of precision engineering relies heavily on CNC (Computer Numerical Control) machinery. From maintaining uniform glass thickness and precise curvature to ensuring perfect adhesion between layers, even the slightest deviation can compromise noise insulation, thermal performance, and safety. Automakers therefore demand exceptionally high-quality standards from window manufacturers, as these components directly impact brand image and, more importantly, driver and passenger safety.

2025-08-26 09:33:38

Soft polyethylene (PE) and polypropylene (PP) waste are widely used in modern plastic industries, including packaging films, agricultural coverings, garbage bags, and logistics materials. Due to their high usage volume and recycling challenges, the effective recovery and processing of these materials have become a critical aspect of sustainable plastic management.

2025-08-25 15:59:12

Machine tools are the cornerstone of modern manufacturing, enabling precise cutting, forming, and machining of metals and other materials. During operation, these machines generate significant friction and cutting heat, which, without proper management, can lead to tool wear, workpiece deformation, and reduced machining accuracy. Lubrication and cooling systems are essential for mitigating these issues, with lubrication reducing friction and wear, and cooling dissipating heat to maintain thermal stability. Together, these systems enhance machining efficiency, extend equipment lifespan, and improve surface quality. Research indicates that effective lubrication and cooling can boost machining performance by up to 30%. This article explores the critical components—lubrication pumps, pipes, coolant pumps, and filters—while highlighting advanced techniques and future trends.

2025-08-22 16:56:48

In the machine tool industry,while spindles and drive systems form the backbone of machine tools, cutting tools and clamping systems directly dictate machining precision and efficiency.Cutting tools perform the material removal, while clamping systems ensure the stable positioning of both tools and workpieces. Together, they determine machining accuracy, efficiency, and surface quality.

2025-08-22 16:15:53

Hot Topic

Agree

.jpg)

.jpg)

.jpg)