Cutting Tools and Clamping Systems in Machine Tools: The Core of Precision and Efficiency

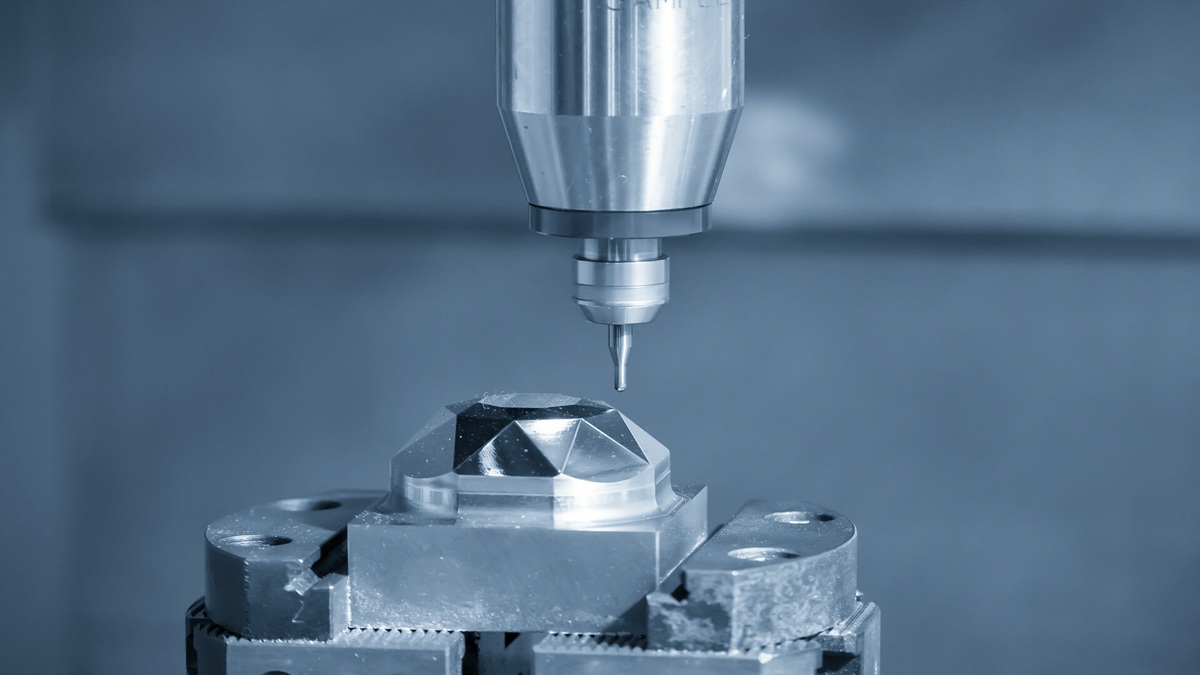

In the machine tool industry,while spindles and drive systems form the backbone of machine tools, cutting tools and clamping systems directly dictate machining precision and efficiency.Cutting tools perform the material removal, while clamping systems ensure the stable positioning of both tools and workpieces. Together, they determine machining accuracy, efficiency, and surface quality.

Published: Aug 22, 2025

Cutting Tools

- Types of Cutting Tools

Turning tools, milling cutters, drills, and taps are among the most common cutting tools. Each machining application requires specific geometries and designs—for example, milling cutters must balance cutting efficiency with chip evacuation, while drills must ensure stability in deep-hole machining.

Ball-end mills are ideal for 3D contouring in mold making, while T-slot cutters are used for machining slots in mechanical structures.

- Tool Materials & Coatings

The material of a cutting tool greatly influences its durability and performance. High-speed steel (HSS) is suitable for medium to low-speed cutting, while carbide excels in high-efficiency machining. Advanced materials like ceramics, CBN (cubic boron nitride), and PCD (polycrystalline diamond) are widely used for hard-to-machine materials. Coating technologies such as TiN and TiAlN enhance wear resistance, heat dissipation, and tool life.TiAlN coatings can extend tool life by 30-50% in high-temperature environments, ideal for machining stainless steel or titanium alloys.

- Tool Maintenance & Management

Regardless of material advancements, proper maintenance and management are critical. Smart tool management systems can monitor tool life and automate tool change scheduling, preventing machining errors or downtime due to tool failure.

Clamping Systems

- Tool Holding

Cutting tools connect to the spindle through tool holding systems, such as BT, CAT, HSK, and Capto. Each specification affects holding rigidity, accuracy, and tool change speed. High-rigidity tool holding minimizes vibration, improving cutting stability and surface finish.

- Workholding

Workpiece clamping is equally crucial. Three-jaw chucks are widely used for turning, while hydraulic and pneumatic fixtures provide fast, precise positioning. Vacuum chucks and magnetic clamps are ideal for thin or non-metallic materials. Precision fixtures shorten setup times and ensure consistency in mass production.

- Latest Developments

Modern cutting and clamping systems increasingly incorporate sensor technologies to monitor clamping force, vibration, and temperature in real time, integrating with CNC systems to enhance smart machining. Automated tool changers and quick-change fixtures further reduce downtime and support high-efficiency production. Also, AI-driven tool monitoring systems predict tool wear, minimizing unplanned downtime.

Conclusion

Cutting tools and clamping systems are at the core of precision and efficiency in machine tools. High-quality tools combined with stable clamping significantly improve cutting performance, extend machine life, and reduce production costs. In the future, with the growth of smart and automated technologies, they will evolve from being mere executors of machining to intelligent nodes in digital manufacturing.

Published by Aug 22, 2025

.png)