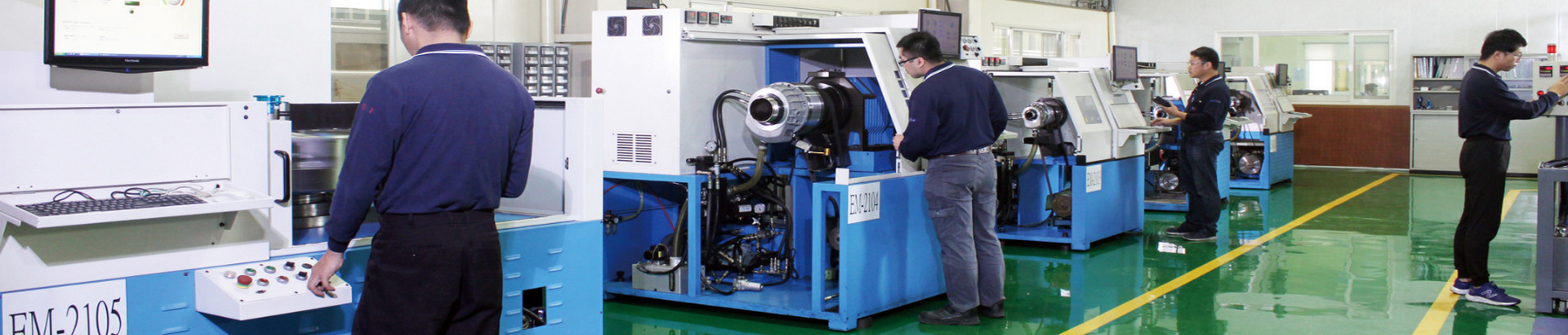

Autogrip Machinery Co., Ltd., established in 1989, is a renowned Taiwanese manufacturer that specializes in the development and manufacture of machine chucks, rotary cylinders, and related parts. Autogrip offers a wide range of lathe chuck products, including power chucks, pneumatic/hydraulic rotary cylinders, facing heads, and clamping products. These exceptionally high-rigidity and high-precision solutions play a crucial role in various industries, ensuring efficient and accurate machining processes.

Comprehensive Product Range

Autogrip's product line boasts several innovative solutions designed to meet a wide range of machining needs. Some of their notable products include:

Power Chucks and Special Purpose Power Chucks:

Power chucks are versatile devices used on lathes, milling machines, drilling machines, and grinding machines. Autogrip offers a range of special purpose power chucks engineered to meet the unique demands of industries such as automotive, aerospace, and medical applications, ensuring optimal performance and efficiency.

Stationary Chucks:

Stationary chucks provide excellent stability and rigidity, and are particularly suitable for heavy-duty machining tasks where secure workpiece fixation is essential.

Pneumatic Rotary Chucks:

Pneumatic rotary chucks provide rapid and efficient clamping solutions, ideal for applications that require quick workpiece changes. These chucks utilize pneumatic pressure to secure workpieces, providing flexibility and time savings in machining processes.

Manual Chucks:

Manual chucks are user-friendly options suitable for various applications. They offer precise clamping through manual adjustment, ensuring ease of use and versatility.

Collet Chucks:

Collet chucks are widely used in precision machining, particularly for components such as optical and electronic parts. Autogrip's collet chucks provide reliable and secure clamping, enabling high-precision machining of intricate workpieces.

Facing Heads:

Facing heads are indispensable tools for facing, grooving, and other lathe operations. Autogrip's facing heads deliver precise machining capabilities, allowing for efficient stock removal and smooth surface finishes.

Synchronous Clamps:

Synchronous clamps ensure simultaneous and uniform clamping of multiple workpieces. This feature is advantageous in high-volume production scenarios, improving productivity and maintaining consistency.

Rotary Cylinders, Valves and Joints:

Autogrip's rotary cylinders offer smooth and reliable rotary motion, facilitating accurate positioning and controlled movements during machining operations. Rotary valves and joints enable the transfer of fluids, gases, or electrical signals in rotating systems, ensuring the smooth functioning of rotary machinery.

Importance and Best Use of Autogrip Products

Autogrip's machine chucks, rotary cylinders, and clamping products play a vital role in various industries, contributing to enhanced precision and efficiency.

Metalworking Industry:

Autogrip power chucks are commonly employed in lathes, milling machines, drilling machines, and grinding machines across the metalworking industry. These chucks facilitate secure workpiece clamping, ensuring the stable transmission of power and torque during machining operations.

Robotics:

Power chucks find applications in robotics, particularly at joints, where high-precision and high-torque movements are required. Autogrip's power chucks ensure precise and reliable performance, contributing to the overall precision and efficiency of robotic systems.

Precision Machining:

In precision machining applications, such as optical and electronic component manufacturing, Autogrip's power chucks play a crucial role. These chucks provide the necessary clamping force and accuracy required to machine intricate components, ensuring exceptional precision and surface finish quality.

Special Considerations in Manufacturing

ISO/IEC 17025 Accredited Mechanical Testing Lab:

Autogrip Mechanical Testing Lab, holding ISO/IEC 17025 accreditation, ensures rigorous testing procedures and reliable product performance. Some tests performed include dynamic gripping force tests, dynamic oil leaking tests, rubber collet fatigue tests, pneumatic chuck tests, and power indexing tests. These procedures guarantee that Autogrip's products meet design specifications and provide optimal performance and accuracy.

The Benefits of Being Made in Taiwan:

Taiwan has gained recognition for its solid and durable manufacturing heritage. Taiwanese manufacturing companies, including Autogrip, benefit from a highly skilled workforce and a culture of technical expertise and innovation. These factors contribute to the development of advanced products and efficient manufacturing processes.

Quality, Efficiency, and Cost-Effectiveness

Autogrip focuses on incorporating features that enhance the quality and efficiency of their products, making them cost-effective solutions. These features include:

Rigidity and Durability:

Autogrip products exhibit exceptional rigidity and longevity. The company's emphasis on durability and infallible precision ensures robust, long-lasting, reliable products, able to transmit power and torque effectively.

Precision and Accuracy:

Meticulous design and manufacturing processes contribute to infallible precision and reliable and repeatable performance.

Versatility and Adaptability:

Autogrip's product range caters to diverse machining requirements, offering versatility and adaptability across various industries. This flexibility allows customers to choose the best-suited solution for their specific needs.

As a proud representative of Taiwan's solid and durable manufacturing heritage, Autogrip Machinery Co., Ltd. has established itself as a leading manufacturer of machine chucks, rotary cylinders, and related parts. Autogrip provides diverse, high-quality, efficient, and cost-effective solutions to meet evolving industry demands.