Knowledge

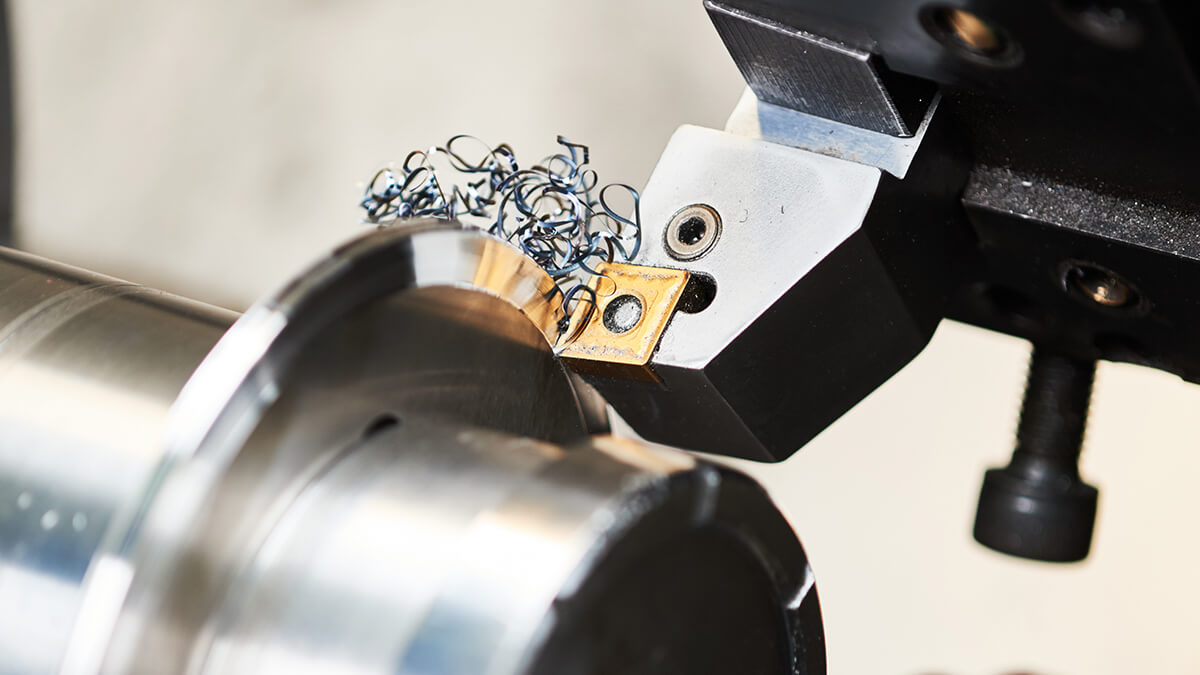

In the cutting of hardware components, a comprehensive analysis of factors is required, and through strict process flow, a suitable cutting process can be planned to manufacture hardware components of stable quality.

2020-08-10 14:00:04

Machine tools refer to power devices used to process work pieces and are important equipment in the manufacturing process of mechanical parts. Machine tools are generally used for forming, cutting, and joining other tools.

2020-08-06 11:36:30

Interest in learning machine learning has skyrocketed in the years since Harvard Business Review article named ‘Data Scientist’ the ‘Sexiest job of the 21st century’. But if you’re just starting out in machine learning, it can be a bit difficult to break into.

2020-08-05 13:26:06

A Bridgeport mill is a standard manual knee-type vertical milling machine. The reason that many people refer to a manual mill simply as a “Bridgeport” is that it’s one of the most famous brand names that’s found in most machine shops.

2020-08-04 14:37:56

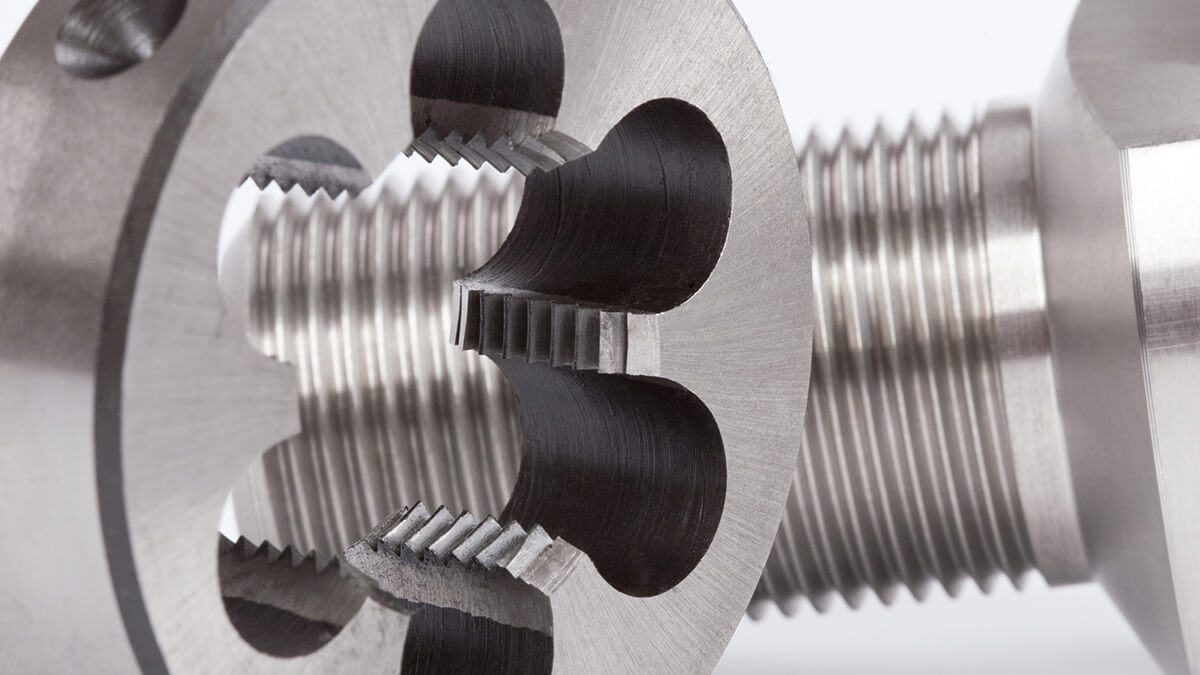

The thread is usually the last feature added to the part. There are other challenges besides the exact parameters required and standard threading issues.

2020-07-29 11:22:50

Welding is a process that uses "heat" and "electricity" to connect two pieces of metal, and the type of welding metal will also affect the welding results and technical requirements; like many professional skills, welding technology also has different levels of difficulty. First understand the most common types of welding introduction, principle teaching, and skill analysis.

2020-07-09 14:35:48

Welding is a method to make two metal blocks belong together. Metal weldability is the ability of metal materials to adapt to the welding process. Under certain welding process conditions, whether it can obtain high-quality welded joints and whether the welded joints can operate safely under use conditions is an evaluation standard.

2020-07-09 13:28:57

Refers to products made by simple processing or the primary processing of raw materials. In machinery, rough-processed products generally refer to products that efficiently remove most of the remaining amount and make the benchmark for subsequent processing.

2020-07-07 17:03:07

Today we are talking about CAD. Computer-aided design (CAD) is the use of computers (or workstations) to aid in the creation, modification, analysis, or optimization of a design.

2020-07-07 13:50:12

Quenching is a heat treatment process for metals and glass. Heating alloy products or glass to a certain temperature, then rapidly cooling in water, oil, or air containing minerals, generally used to increase the hardness and strength of the alloy.

2020-06-29 15:15:50

Hot Topic

Agree