- Showing results for

- Laser Cutting Machine

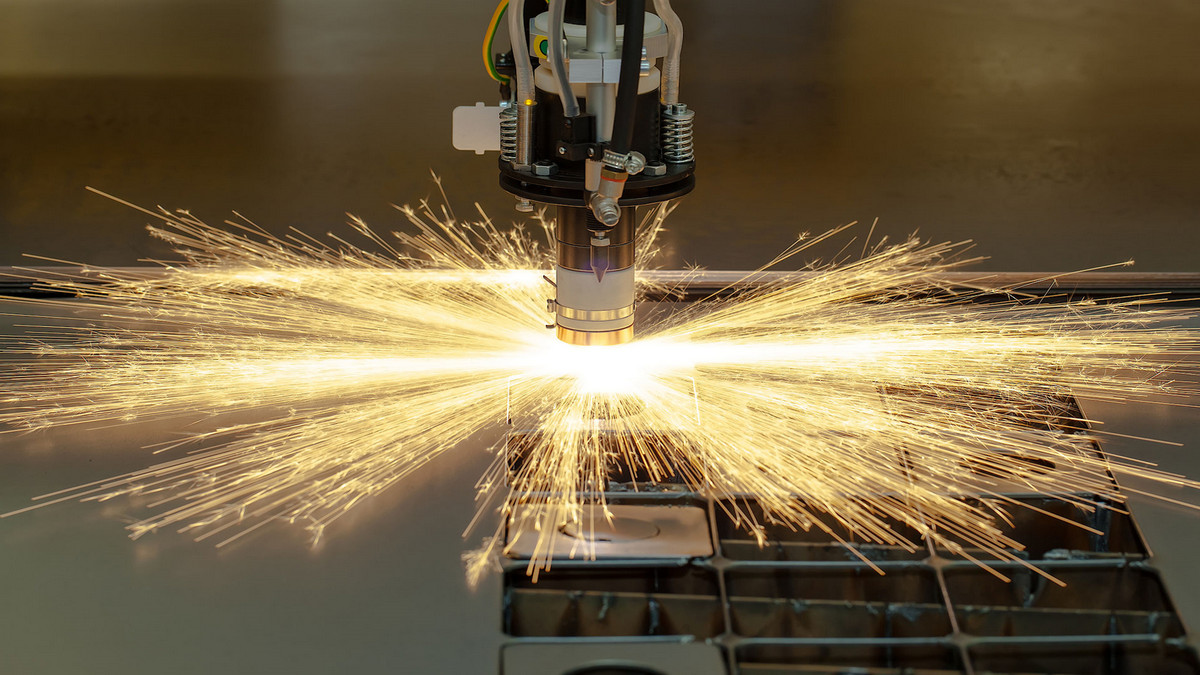

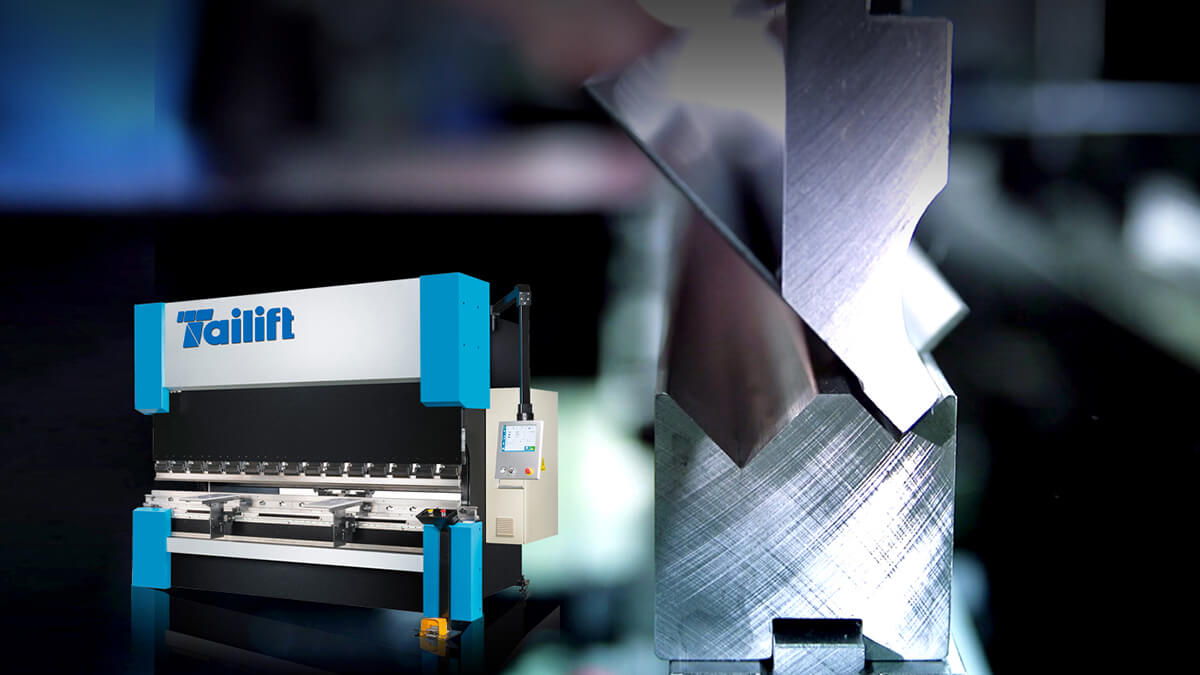

In today's fast-paced world, the global manufacturing industry is undergoing a profound transformation driven by intelligence and automation, with the sheet metal processing industry following suit. Merely focusing on product quality is no longer enough to satisfy the dynamic demands of today’s market. Integrating highly efficient and intelligent production systems has become essential for enterprises to secure a competitive advantage. Tailift Co., Ltd., leveraging over 40 years of technical expertise and strong manufacturing capabilities, continues to lead this innovative wave in the sheet metal processing sector.

2025-08-29 14:25:21

In an era where electronic component manufacturing increasingly demands high precision and stability, the laser trimmer has evolved from a supplementary device into an indispensable core tool. Its introduction has fundamentally transformed the fabrication of resistors, sensors, and hybrid circuits, propelling the electronics industry toward micron-level precision and the future of smart manufacturing.

2025-08-21 15:55:32

In light of the evolving global industrial demands, the laser industry and technology are shifting towards meeting the requirements of 5G semiconductors and advanced processes for smart vehicles. While Taiwan's laser industry has made substantial progress over the years, maintaining alignment with international advancements necessitates a proactive push in independent laser technology.

2023-11-17 14:07:13

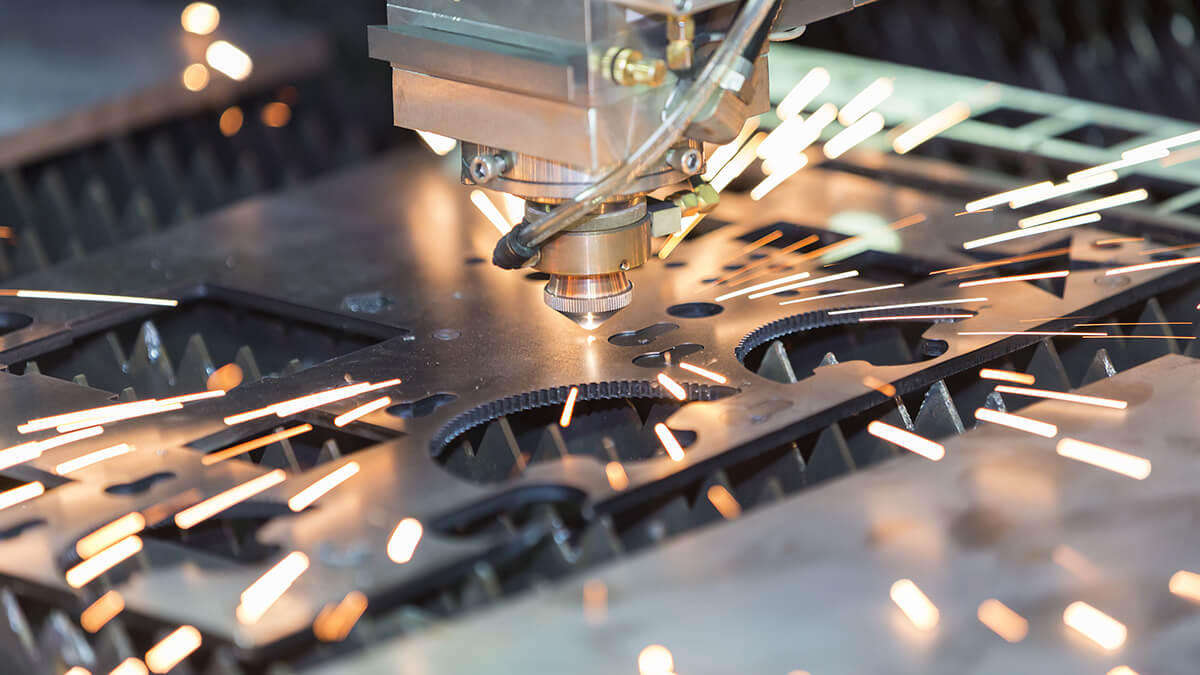

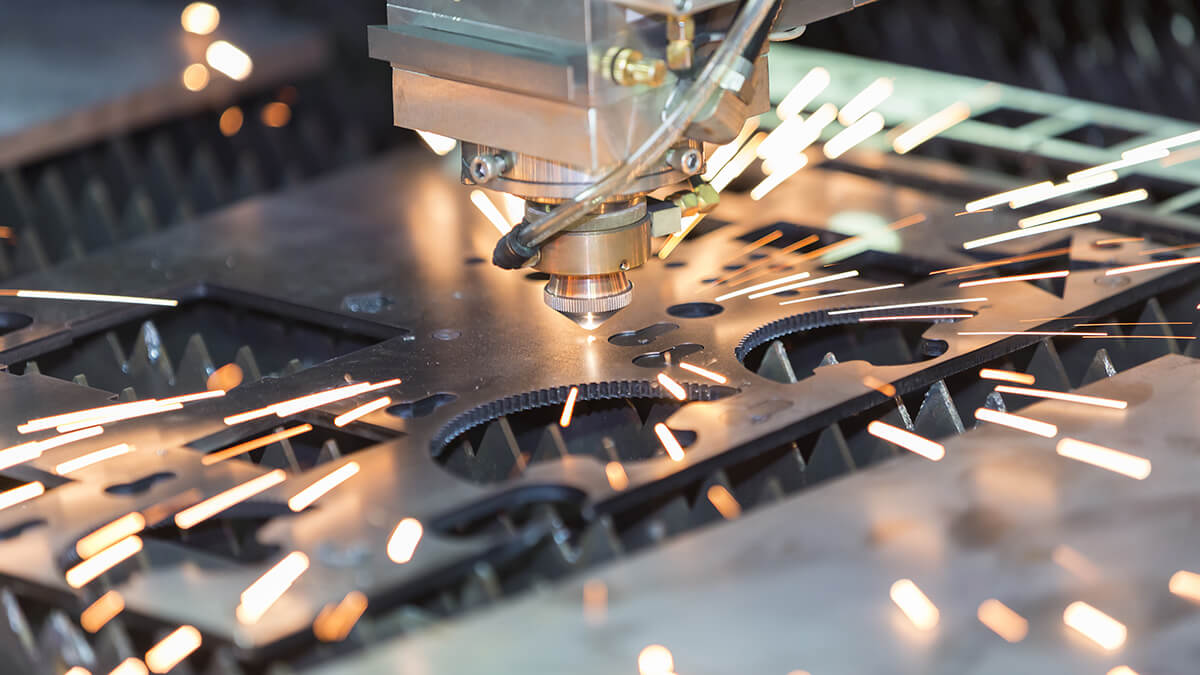

When comparing laser cutting technology to traditional cutting methods, laser cutting offers superior precision, as it utilizes a high-intensity laser beam to cut through materials with exceptional accuracy, even for intricate details.

2023-11-07 13:59:00

Cutting technology encompasses various processing methods, with laser cutting being capable of fulfilling intricate and highly precise cutting demands. It is a prevalent technique widely used in industrial manufacturing.

2023-11-07 13:34:10

Laser cutting technology Compared with traditional cutting, the laser cutting process has better accuracy, and precise details are cut through a high-intensity laser beam.

2023-08-31 09:54:11

In response to the development of international industry demand, the laser industry and technology have begun to develop towards 5G semiconductors and smart vehicle process requirements. Taiwan’s laser industry has developed for many years and has a solid foundation, but to continue to keep up with the international pace, the need for independent laser technology step up.

2023-05-04 09:58:42

Lasers are used in a wide range of industries, especially in processing. The entire laser processing industry is currently moving in the direction of high power, ultra-short pulse, and intelligence.

2022-12-07 14:41:24

In response to the development of international industry demand, the laser industry and technology have begun to develop towards 5G semiconductors and smart vehicle process requirements. Taiwan’s laser industry has developed for many years and has a solid foundation, but to continue to keep up with the international pace, the need for independent laser technology step up.

2020-09-28 11:18:01

Machine tools refer to power devices used to process work pieces and are important equipment in the manufacturing process of mechanical parts. Machine tools are generally used for forming, cutting, and joining other tools.

2020-08-06 11:36:30

The revenue of the laser industry grows higher and higher in recent years. As manufacturing industry moves toward smart, intelligence and systematization, the laser manufacturing process has become an indispensable role in the manufacturing industry.

2020-06-17 11:27:03

The word comes from the English called plate metal. Generally, some metal sheets are plastically deformed by hand or die-stamping to form the desired shape and size and can be further formed by welding or a small amount of mechanical processing to form more complex parts.

2020-06-16 14:42:40

Laser cutting technology Compared with traditional cutting, the laser cutting process has better accuracy, and precise details are cut through a high-intensity laser beam.

2020-03-23 15:24:56

Cutting technology has many different processing techniques, and laser cutting can perform more complex and precise cutting requirements, which is also a common processing technique in industrial manufacturing.

2020-03-23 15:11:07

Agree