- Showing results for

- Precision Machining

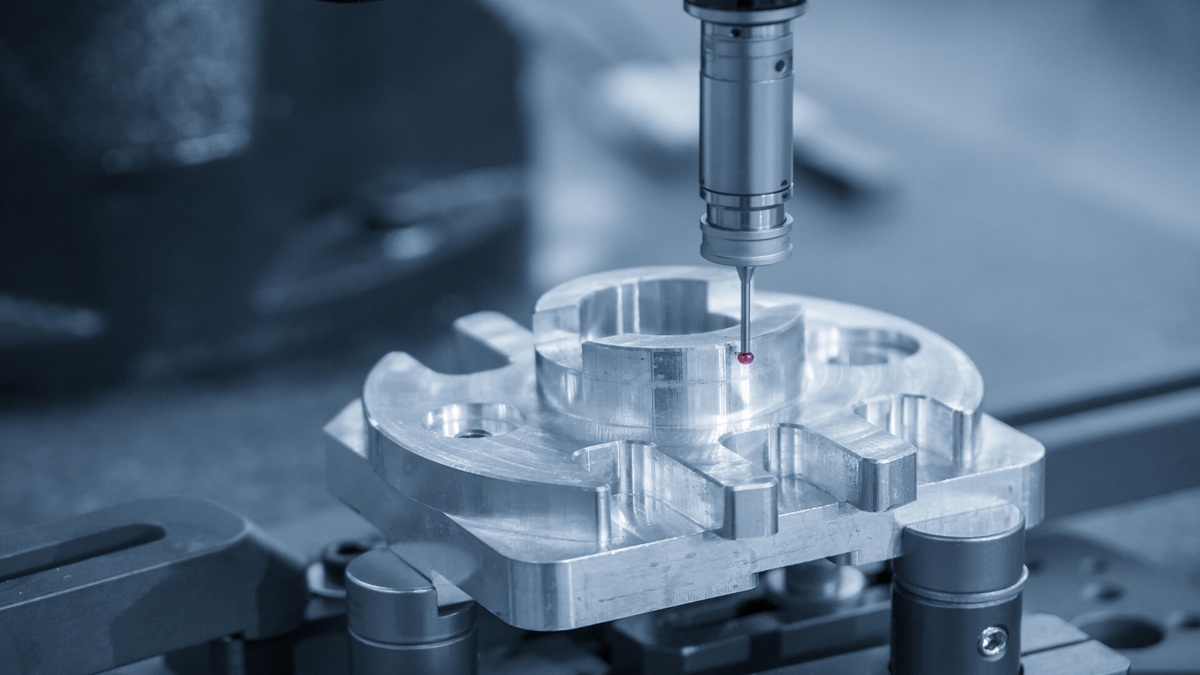

The global precision manufacturing industry is facing unprecedented challenges: completing complex, multi-angle workpieces within tight deadlines while maintaining stringent precision. In this environment, five-axis machining has become a critical key to boosting corporate competitiveness. TOP SDISK (Spintop Machinery Co., Ltd.) tackles this challenge head-on by leveraging industry-leading direct drive motors and cam technology to build high-speed, high-rigidity double-axis CNC rotary tables, injecting intelligence and innovation into the manufacturing sector.

2025-08-27 15:56:14

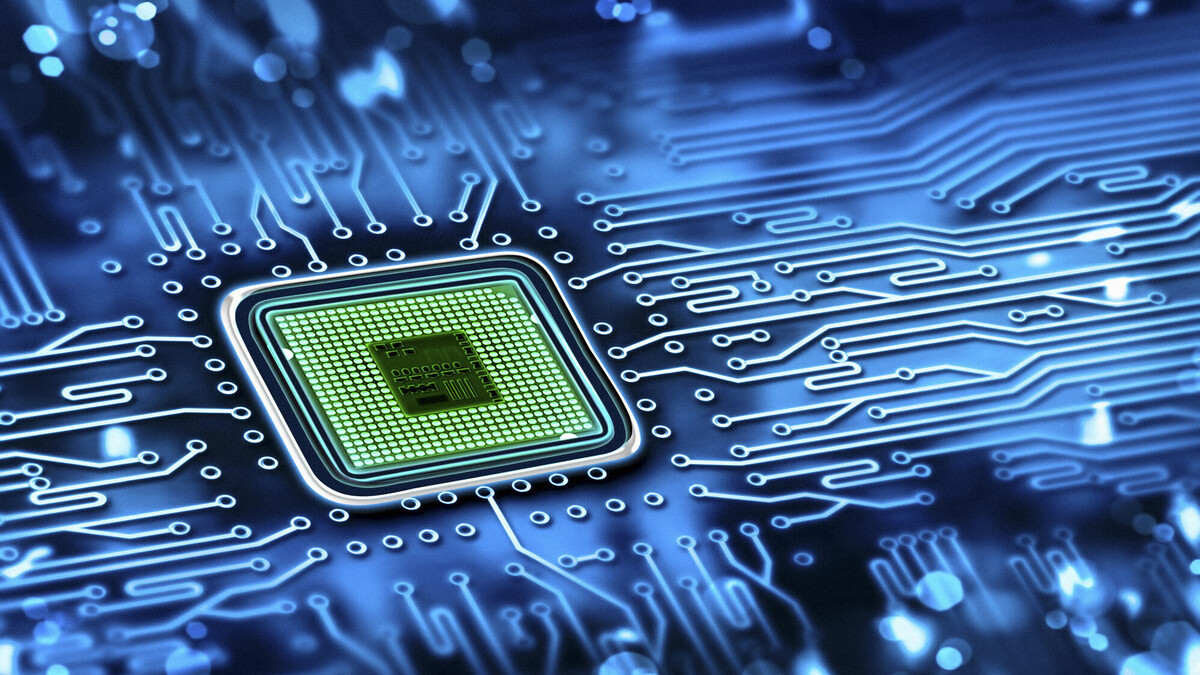

Every time we pick up a smartphone, we experience lightning-fast performance—but we rarely think about the hidden “precision secrets” behind it. One of the unsung technologies supporting the entire semiconductor manufacturing chain is the CNC machine. Every step, from wafer slicing to packaging, demands absolute nanometer-level precision—any tiny error can render an entire chip useless. This is a little-known factor that can determine market leadership.

2025-08-21 15:23:49

Textile fiber is the fundamental element that determines fabric performance and product suitability. Whether you are a designer, manufacturer, or consumer, understanding the unique characteristics of different fibers and their suitable applications is crucial for precise material selection and informed purchasing. This article will systematically introduce the applications of major natural and synthetic fibers and explain how blending them can overcome the limitations of single fibers, providing versatile functional solutions and helping you build a comprehensive knowledge base of textile applications.

2025-08-12 11:55:48

Jin He Feng in Taiwan, specializes in the customized design and manufacturing of aluminum alloy ladders and industrial work platforms. The company is dedicated to enhancing safety and operational efficiency for various industries engaged in elevated work. From site measurement and design drafting to final product delivery, every solution is tailor-made by a professional team to meet specific on-site requirements and to fulfill enterprise-level standards for safety, durability, and ease of operation.

2025-08-11 15:57:17

Modern smart factories often face challenges with scattered data and information silos. Although sensors, SCADA, MES, and other systems continuously generate vast amounts of data, the lack of integration makes it difficult to quickly identify the root causes of anomalies. Large language models (LLMs) are emerging as a key solution by enabling cross-system data retrieval and analysis through natural language queries. Acting as “semantic coordinators” within multi-agent manufacturing systems, LLMs can dynamically adjust production schedules and resource allocation in real time. The article references examples from Microsoft Azure AI, AWS, Schaeffler, and Siemens to demonstrate how LLMs help reduce downtime, increase transparency, and improve decision-making efficiency. Finally, it highlights that as LLMs integrate with automation and visualization technologies, manufacturing will enter the “semantic era,” where operators can access production line insights conversationally and instantly, driving smart manufacturing toward greater flexibility and intelligence.

2025-08-11 09:24:14

Every textile product tells a story about its fibers. Its appearance, feel, and performance are all intricately linked to the textile fibers that make it up. Understanding the physical properties (e.g., strength, elasticity) and chemical properties (e.g., moisture absorption, heat resistance) of fibers is key to grasping the core value of a textile product. This article aims to systematically dissect the secrets of natural, man-made, and innovative fibers, building a comprehensive knowledge system for readers.

2025-08-08 11:36:26

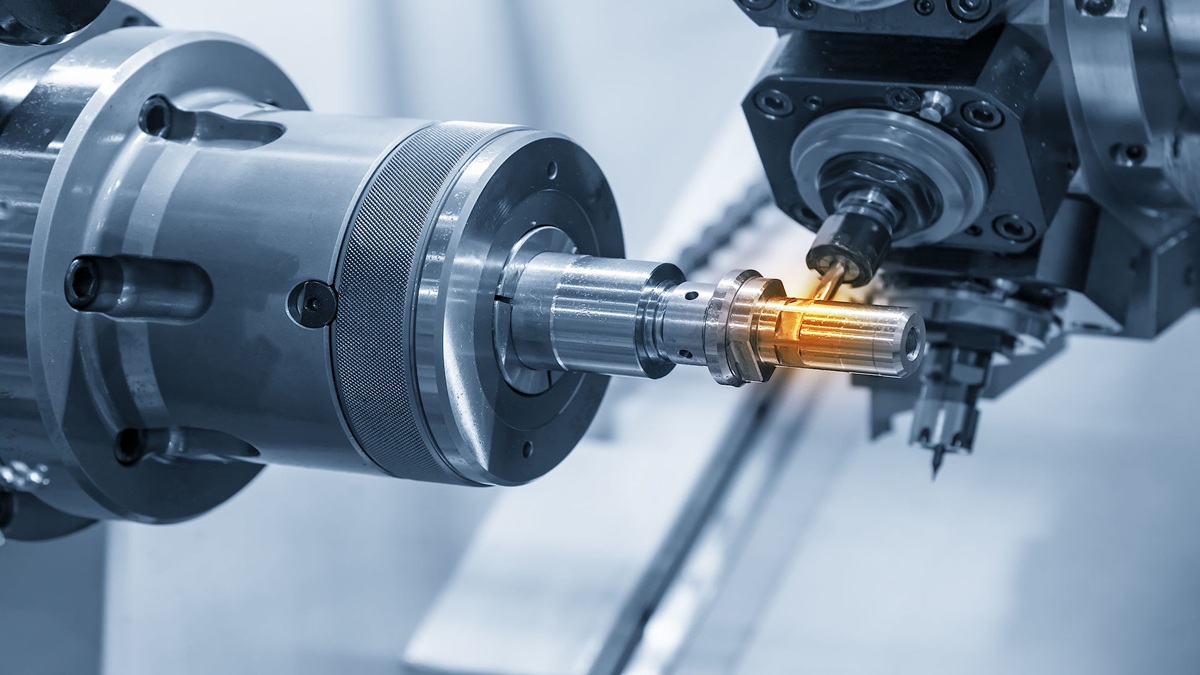

The traditional manufacturing industry relied on skilled artisans manually operating lathes, meticulously shaping perfect components with hand tools. However, as times have rapidly changed, lathes have evolved from manual machines into automated equipment. Now, instead of manual carving, engineers can produce parts simply by inputting a program. The emergence of big data, AI, and the Internet of Things (IoT) has brought another wave of impact to the industry, signaling that a new manufacturing revolution is on the horizon.

2025-08-08 10:28:10

With the rapid development of industries such as aerospace, medical equipment, new energy, and high-end electronics, there's an increasing demand for materials with properties like lightweight, high strength, high temperature resistance, and corrosion resistance. This has led to the widespread application of advanced materials such as titanium alloys, nickel-based superalloys, and carbon fiber reinforced plastics (CFRP). While these materials offer excellent performance, their processing presents severe challenges to traditional machine tools due to issues like high hardness, poor thermal conductivity, and a tendency to work-harden. However, this has also become a powerful force driving machine tool innovation and upgrades, prompting machine tool manufacturers to seek breakthroughs in precision, rigidity, thermal stability, and multi-tasking technology.

2025-08-08 08:37:41

In the world of precision machining, the spindle is the "heart" of a machine tool. Its stable operation is crucial for machining quality and production efficiency. Without a healthy spindle, even the most advanced machine can't reach its full potential. Mastering its troubleshooting, daily maintenance, and emergency handling techniques is key to ensuring your machine tool operates efficiently and lasts longer

2025-08-05 16:13:16

A great fisherman often stands at the shore, gazing at the vast ocean—not knowing whether the voyage ahead holds calm waters or turbulent storms—yet sets sail with unwavering conviction, simply for the chance of a fruitful catch. COMORK’s General Manager, Quan-ji Zhou, has also weathered his share of tides at sea. Even in the face of uncertainty, he pressed forward, sharpening his intuition and building a resilient character. Today, this very spirit forms the cornerstone of his leadership at COMORK. From the open waters to the factory floor, Zhou has carried the fisherman’s fearless and explorative mindset into every precision grinding machine, steering COMORK steadily toward the global market.

2025-08-05 10:53:20

In the world of precision machining, cutting tools play a vital role. They directly determine cutting efficiency, machining accuracy, and the final product's surface quality. Even with the most advanced CNC machine tools, without the right cutting tools, their full potential can't be realized. Therefore, mastering these advanced techniques will help you achieve outstanding results in complex machining tasks while optimizing production costs.

2025-08-04 15:43:57

The manufacturing industry is currently at a critical crossroads of dramatic change. With the advent of Industry 5.0 and the wave of digital transformation, product designs are becoming increasingly complex, and material selections are trending towards high hardness and difficult-to-machine properties. This presents a true test for the machining tools responsible for the final product quality. Industries such as molds, semiconductors, optics, and aerospace no longer just demand that tasks be "done," but that they be "done precisely, efficiently, and sustainably." Traditional tools often fall short in durability, precision, and efficiency when facing high-hardness materials like tungsten carbide and ceramics, as well as complex, confined geometric spaces. The market not only needs tougher tools but also solutions that can adapt to smart manufacturing trends, improve overall yield, and reduce total costs.

2025-08-02 16:54:38

The global manufacturing industry is rapidly evolving, and companies need to find partners who are efficient, high-quality, and capable of integrated services to maintain competitiveness. Jinholly Co., Ltd., a Taiwan-based company deeply rooted in precision metal processing, is providing clear solutions for this industrial transformation through its unique "one-stop" service model.

2025-07-30 13:49:41

Artificial intelligence and automation technologies are advancing at a rapid pace, driving large‑scale deployments of robots across manufacturing, healthcare, logistics, and service sectors. This momentum is propelling overall industry upgrades and operational efficiency leaps. Amid this wave, mastering the manufacture of high‑precision, high‑reliability core components has become the decisive factor in market competitiveness.

2025-07-29 16:12:44

As global concerns over environmental protection and food safety continue to grow, plastic processing and packaging equipment are undergoing a transformative shift. Taiwanese machinery manufacturers are leveraging automation, biodegradable material processing capabilities, and modular design to secure strong competitive advantages—especially in the production of everyday consumables like straws, strapping bands, shrink film, and cotton swabs

2025-07-25 14:13:20

Through ultrasonic-assisted processing technology, hard and brittle materials can be processed easily, reducing-edge chipping and improving surface quality.

2023-07-14 13:30:04

A grinding machine, or grinder is a widely used abrasive processing process in which a spinning wheel is covered with coarse grains. Cutting pieces of metallic or non-metallic substances from a workpiece to make the surface flat or smooth.

2023-04-12 13:31:11

Ultra-precision machining technology is an important way to improve the performance, quality, service life and reliability of electromechanical products, as well as saving materials and energy. For example: improving the machining accuracy of cylinders and pistons can improve the efficiency and horsepower of automobile engines and reduce fuel consumption; improving the machining accuracy of rolling elements and raceways of rolling bearings can increase the speed of bearings, reduce vibration and noise; improve flatness of processing of magnetic disks, thereby reducing the gap between it and the magnetic head, can greatly increase the storage capacity of the magnetic disk; improving the marking accuracy of the semiconductor device (reducing the line width, increasing the density) can improve the integration of the microelectronic chip, etc.

2023-04-12 13:24:51

A grinder is a widely used abrasive processing process in which a spinning wheel is covered with coarse grains. Cutting pieces of metallic or non-metallic substances from a workpiece to make the surface flat or smooth.

2022-12-28 17:14:24

Through ultrasonic-assisted processing technology, hard and brittle materials can be processed easily, reducing-edge chipping and improving surface quality.

2022-12-08 14:47:34

Agree

.jpg)