- Showing results for

- Industry 4.0

In today's fast-paced world, the global manufacturing industry is undergoing a profound transformation driven by intelligence and automation, with the sheet metal processing industry following suit. Merely focusing on product quality is no longer enough to satisfy the dynamic demands of today’s market. Integrating highly efficient and intelligent production systems has become essential for enterprises to secure a competitive advantage. Tailift Co., Ltd., leveraging over 40 years of technical expertise and strong manufacturing capabilities, continues to lead this innovative wave in the sheet metal processing sector.

2025-08-29 14:25:21

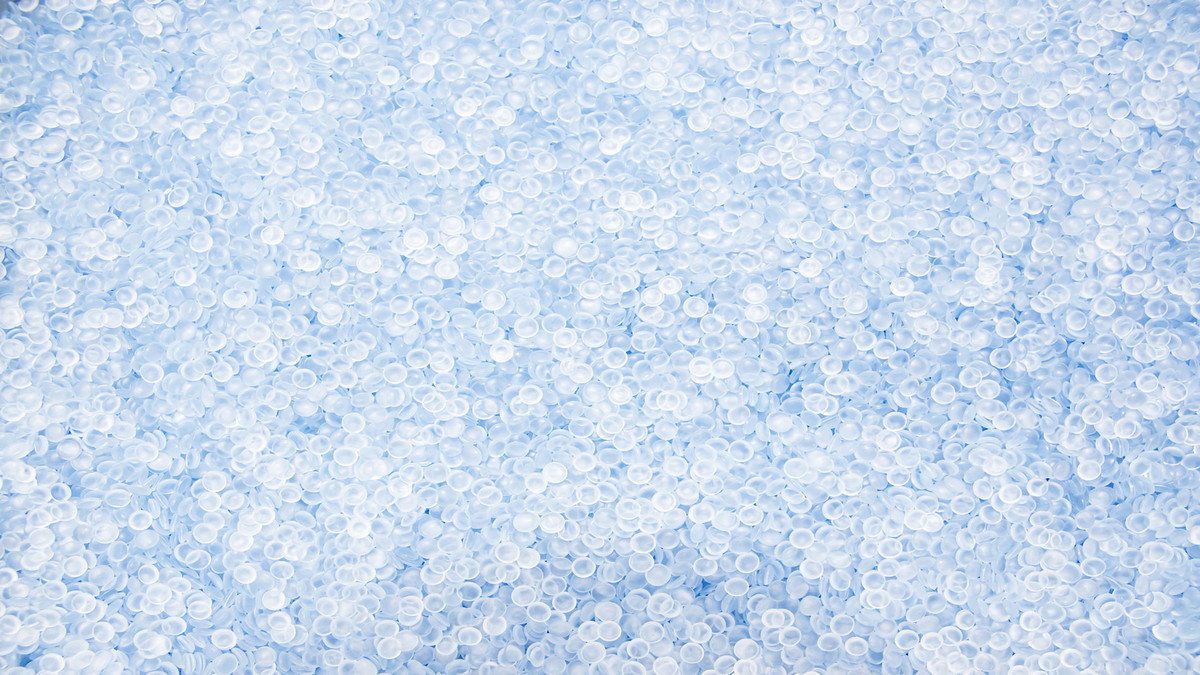

Since its establishment in 1984, Shang Ta Chia Industrial Co., Ltd. (STC Machinery) has focused on the design and manufacturing of plastic sheet extrusion lines, accumulating over forty years of independent R&D experience. As the global plastics industry undergoes transformation and upgrading, the company not only provides high-performance extrusion equipment but also assists clients in enhancing production capacity and efficiency with a rigorous quality control system and innovative technologies, propelling the entire industry chain toward intelligent and sustainable development.

2025-08-28 12:15:29

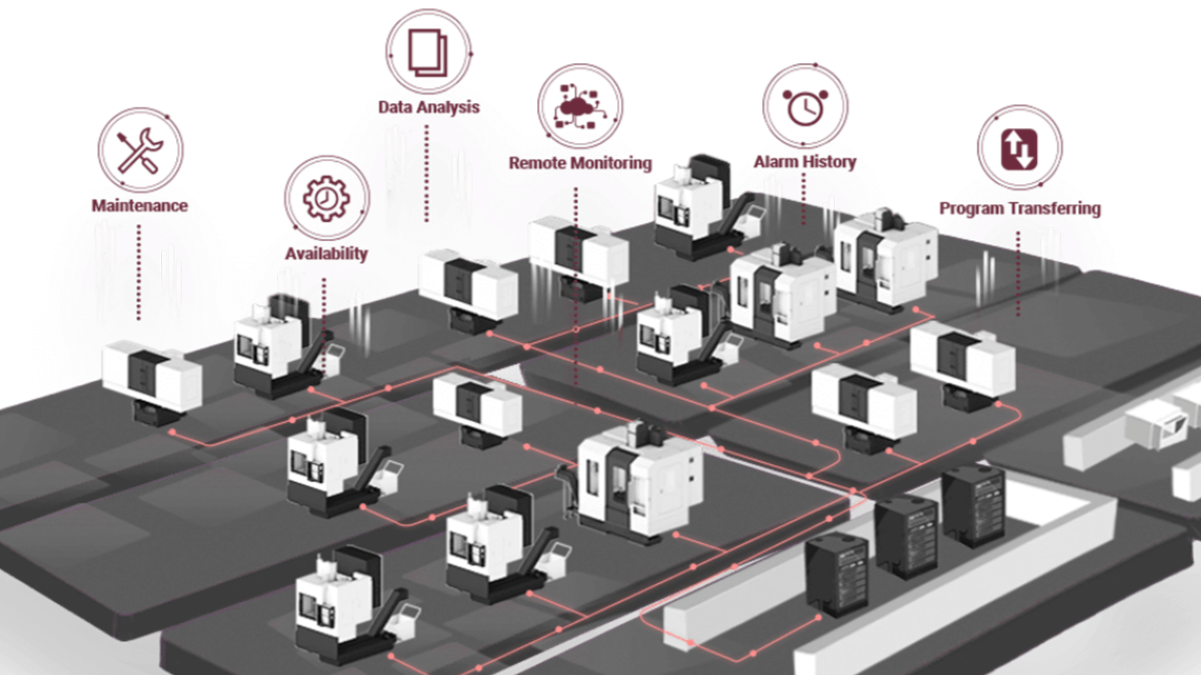

In 2025, as global manufacturing continues its rapid digital transformation, the machine tool industry is facing significant change. International buyers in aerospace, electric vehicles, and high-end electronics are increasingly prioritizing smart services and data applications over mere machining precision. Taiwan's machine tool industry is actively integrating the Internet of Things (IoT), artificial intelligence, and big data technology, expanding from traditional hardware manufacturing into the smart solutions sector. This move helps global manufacturing clients boost production efficiency and enhance equipment maintenance management. This article will delve into how Taiwan's machine tool industry is becoming an indispensable smart partner for global manufacturing, delivering sustained value.

2025-08-27 14:56:00

In the global manufacturing industry’s shift toward Industry 4.0, smart upgrades are no longer optional—they’re essential for staying competitive. At the core of this transformation is the conversion of traditional factories into data-driven, smart ecosystems. This complex undertaking isn’t something companies can tackle alone. A series of policies and international collaborations, from governments’ high-level strategies to industry alliances’ communication standards, are paving the way for smart manufacturing. This allows technologies like remote monitoring and predictive maintenance to move from blueprints to reality more quickly, fundamentally changing how factories operate worldwide.

2025-08-21 16:07:37

The manufacturing world is in the midst of a digital revolution. As Industry 4.0 rapidly evolves, factories are transforming from traditional workshops into interconnected, intelligent ecosystems. This shift is not just about adopting new technology; it's about fundamentally changing how we produce goods. Leading the charge are smart machine tools, which are moving beyond simple automation to become autonomous, data-driven assets. This is where companies like CHEVALIER are making their mark, bridging the gap between hardware excellence and digital innovation to redefine the factory of the future.

2025-08-21 16:03:05

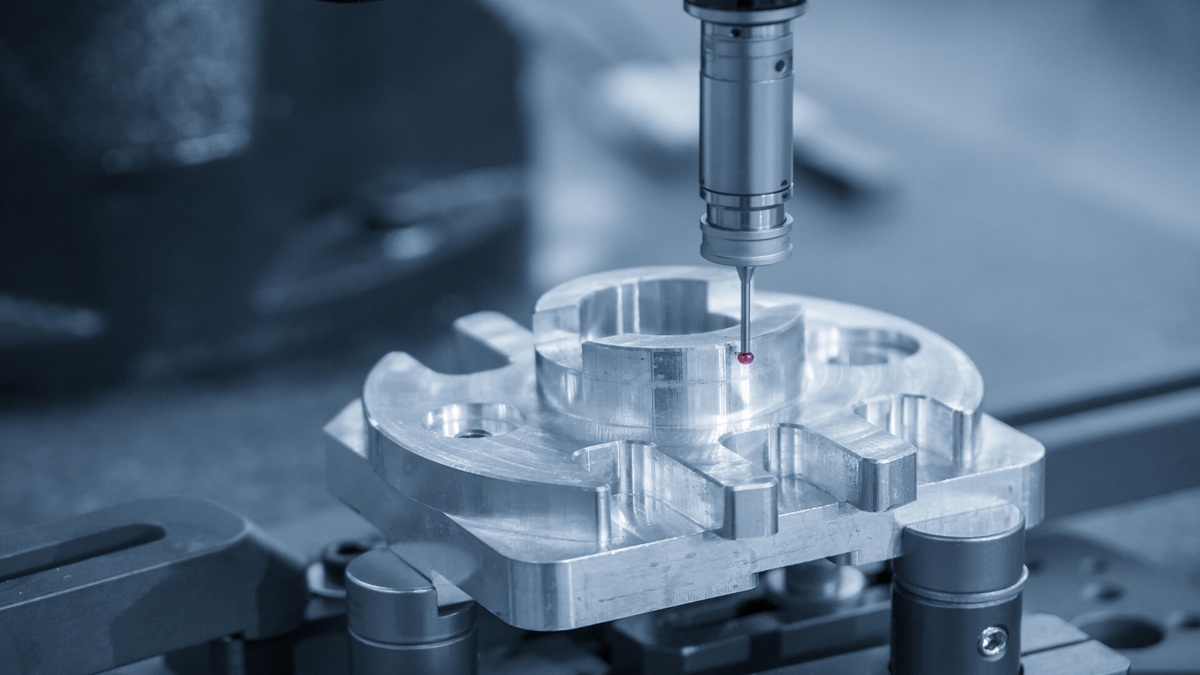

The global manufacturing industry is experiencing a profound transformation towards intelligence and precision. Market demands for higher precision, greater efficiency, and flexible production are increasingly urgent. Facing the challenges of high-mix, low-volume (HMLV) flexible manufacturing, enterprises critically need to balance high-precision machining with rapid responsiveness. TOP-ONE Machinery Co., Ltd. , leveraging its deep expertise in precision CNC machine tool R&D and exceptional customization capabilities, is actively engaging in this transformation. We are committed to empowering global clients to overcome transformation challenges and enhance manufacturing competitiveness through innovative solutions.

2025-08-21 12:15:18

As the global manufacturing and logistics industries rapidly transform toward intelligence and sustainability, intelligent automated warehousing and smart logistics systems have become core technologies enabling enterprises to improve operational efficiency, reduce costs, and enhance market competitiveness. Tailift Co., Ltd., with over 50 years of rich experience, focuses on technological innovation in automated warehousing and logistics systems, continuously providing precise digital transformation solutions to clients across various industries. From high-performance warehouse design to fully automated logistics operations, Tailift is leading technological innovation in the industrial field.

2025-08-20 13:45:41

In aerospace, automotive, and high-performance manufacturing industries, advanced alloys (such as titanium alloys and nickel-based superalloys) and composites (such as thermoplastic carbon fiber composites) are becoming mainstream due to their lightweight, high strength, and high-temperature resistance. By 2025, the global aerospace composite market is expected to expand rapidly with an annual compound growth rate of about 13.9%, driven by the demand for environmental protection and net-zero emissions, which will further innovate and apply thermoplastic composite technologies. These new materials present challenges such as high hardness, tool wear, heat management, and processing deformation control, requiring processing equipment to have higher rigidity, precision, and thermal stability. Additionally, the production process's demand for rapid prototyping, modular assembly, and recycling drives the simultaneous upgrading of materials and equipment.

2025-08-13 14:50:48

Vertical injection molding machines, owing to their unique structural design and operational advantages, are widely used in electronics, medical devices, automotive components, and high-precision plastic part manufacturing. They are especially indispensable for insert molding and in-mold decoration (IMD) processes. As global manufacturing advances toward smarter, higher-efficiency operations, the vertical injection molding machine market is showing several clear trends.

2025-08-12 12:01:38

Modern smart factories often face challenges with scattered data and information silos. Although sensors, SCADA, MES, and other systems continuously generate vast amounts of data, the lack of integration makes it difficult to quickly identify the root causes of anomalies. Large language models (LLMs) are emerging as a key solution by enabling cross-system data retrieval and analysis through natural language queries. Acting as “semantic coordinators” within multi-agent manufacturing systems, LLMs can dynamically adjust production schedules and resource allocation in real time. The article references examples from Microsoft Azure AI, AWS, Schaeffler, and Siemens to demonstrate how LLMs help reduce downtime, increase transparency, and improve decision-making efficiency. Finally, it highlights that as LLMs integrate with automation and visualization technologies, manufacturing will enter the “semantic era,” where operators can access production line insights conversationally and instantly, driving smart manufacturing toward greater flexibility and intelligence.

2025-08-11 09:24:14

In the current wave of global manufacturing transformation, digitalization and connectivity have become the core drivers propelling the machine tool industry toward smart factories. This goes beyond merely connecting traditional equipment to networks; it involves leveraging data collection, analysis, and application to achieve comprehensive optimization of production processes, enhanced efficiency, and flexible manufacturing. From single-machine intelligence to production line collaboration, digitalized and connected technologies are rapidly transforming the design, manufacturing, operation, and maintenance of machine tools.

2025-08-08 09:15:57

In the field of manufacturing and supply chain, the technical assistance of Industry 4.0 and 5G and AI, combined with blockchain, can promote the new development of manufacturing and achieve more effective integration of hardware, software and services.

2023-06-26 13:24:38

With the application of rubber and plastic more and more widely, rubber and plastic machinery is becoming more and more intelligent.

2022-12-29 11:23:29

The building materials construction industry is an important part of economic development, ranging from the construction of national public works to the home life of the general public, all of which are related to the building materials construction industry.

2022-10-03 15:41:37

Germany is the second-largest producer of machine tools in the world, after China. Advanced German machine tool technology has led the development of the machine tool market.

2022-05-16 16:41:57

Smart manufacturing utilizes advanced manufacturing technology and provides solutions through AI, the Internet of Things, big data, cloud, edge computing, and other technologies to substitute the production process with an intelligent manufacturing model and customize products according to customer needs.

2022-04-12 13:09:50

4.0 Automation technologies, through the IIoT (Industrial Internet of Things) connect, control and monitor networks of manufacturing and processing machines, devices, robots and cloud information in real time via Cloud Monitoring. This allows them to learn, operate and function automatically, minimizing human intervention and optimizing production.

2022-03-23 15:11:57

Industrial Internet of Things (Indusrial IoT, or IIoT) is the expansion and use of the Internet of Things (IoT) in industrial applications. Industrial IoT focuses on machine-to-machine (M2M) communication, big data, and machine learning (ML) to make industrial operations more efficient and reliable. IIoT covers the entire industrial application, including robotics, medical equipment, and software-defined production processes.

2021-09-22 18:48:57

The goal of Making Indonesia 4.0 is to achieve Indonesia’s entry into the top ten economies in the world by 2030. The roadmap of Indonesia’s Industry 4.0 is the key to enhancing the overall competitiveness of Indonesia’s industry in the future digital era, guiding the implementation of Indonesia’s national strategy, and where the interests are at stake. Cooperation and coordinated implementation between various industries aim to promote inclusive national growth and sustainable community welfare.

2021-07-06 14:53:47

As industry 4.0 technology continues to advance, existing data can be harnessed to develop machine-learning solutions that deliver real value, optimize decision making, increase flexibility, and attract top talent.

2020-10-30 10:44:26

Agree

點-m-90454917_m.jpg)