The global manufacturing industry is rapidly evolving, and companies need to find partners who are efficient, high-quality, and capable of integrated services to maintain competitiveness. Jinholly Co., Ltd., a Taiwan-based company deeply rooted in precision metal processing, is providing clear solutions for this industrial transformation through its unique "one-stop" service model.

Photo by https://www.jinholly.com/webls-en-us/msg/processing-equipment.html

A Comprehensive Analysis of Core Strengths and Advantages

Jinholly is not just a traditional processing factory but provides a complete "one-stop" integrated solution from design, development to inspection and packaging. This is the key advantage that allows it to stand out in a fiercely competitive market.

From Startup Background to Outstanding Development

Jinholly’s development journey is a continuous pursuit of excellence. Starting from a solid technical foundation, they have gradually expanded their service scope and process capabilities, eventually becoming a professional manufacturer capable of providing comprehensive solutions. This spirit of continuous growth and deepening expertise is the cornerstone of Jinholly’s stable position in the industry.

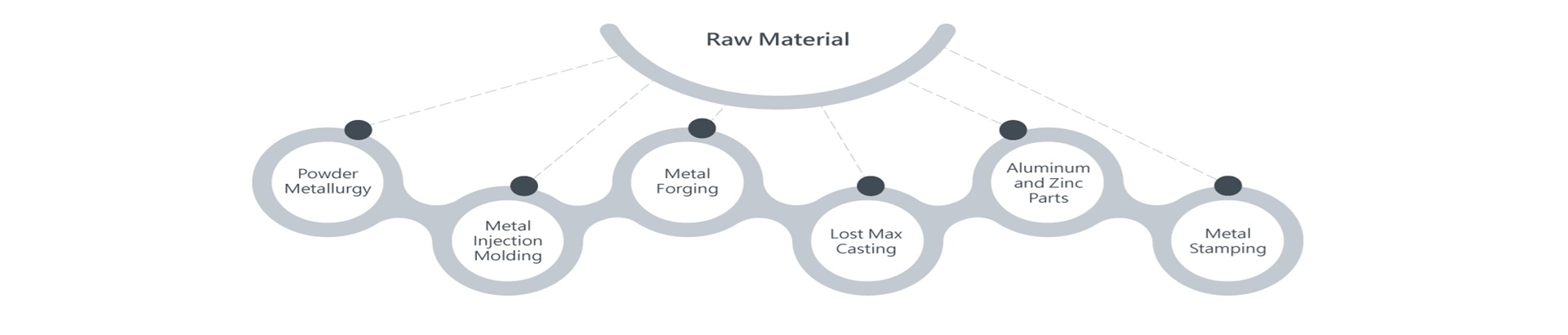

Jinholly’s core business covers a variety of metal forming processes, demonstrating both technical breadth and flexibility:

- Powder Metallurgy: Manufacturing complex shaped parts with high precision and material utilization.

- Metal Injection Molding (MIM): Suitable for producing small, complex, and precise metal parts.

- Investment Casting: Used for manufacturing high-quality, dimensionally accurate complex castings.

- Forging: Producing products with good physical properties, high strength, and toughness.

- Aluminum Alloy Processing: Combining multiple methods to meet various industry needs for lightweight and different hardness.

- Metal Stamping: Using molds and pressure to quickly form metal sheets into required parts, suitable for mass production.

Additionally, Jinholly possesses complete secondary processing capabilities, including CNC turning, milling, drilling and tapping, grinding, heat treatment, polishing, surface treatment, and electroplating, ensuring products meet stringent quality and surface standards while greatly simplifying customers’ supply chain management.

Market Insights and Integration Advantages

Facing challenges of customization, high efficiency, and strict cost control in manufacturing, Jinholly fully understands the importance of "one-stop" services. Its core competitive advantages include:

→ Professional evaluation and solution recommendations to select the best manufacturing plan according to customer needs.

→ Supply chain integration to effectively shorten the supply chain and reduce coordination complexity.

→ Improving efficiency and reducing costs to ensure production efficiency and delivery flexibility.

→ Strict quality control, maintaining high quality and consistency from parts to packaging.

This customer-oriented comprehensive solution is the future trend in manufacturing, helping clients gain a competitive edge in a fiercely competitive market.

Innovative Applications and Metal Processing Outlook

Jinholly’s precision processing products are widely applied across multiple key industries, showcasing their strong capabilities in metal parts manufacturing and indicating their expanding influence across sectors:

Industrial applications: Providing high-precision components required by various industrial equipment.

Automotive industry: Producing automotive parts that meet strict standards, promoting vehicle lightweighting and performance enhancement.

Power and pneumatic tools: Supplying durable, precise key components.

Hand tools: Ensuring the reliability and service life of hand tool products.

Medical devices: Providing precision parts that meet medical-grade requirements, critical to human safety and functionality.

Sporting goods: Lightweight and high-strength parts that improve sports performance and equipment durability.

Jinholly’s professional team continuously acquires new knowledge, striving to enhance expertise and constantly integrate resources for clients to create higher product value. This means Jinholly will keep investing in technology research and development, actively exploring the latest trends in lightweight materials, precision micro parts, and intelligent manufacturing process integration to meet higher future market demands. Facing the digitalization and sustainability wave in global manufacturing, Jinholly is ready to meet challenges and lead innovation.

Collaborate to Reach New Industry Heights

If you are seeking a reliable partner offering integrated solutions with extensive metal processing experience, now is the best time to contact Jinholly. Visit Jinholly’s official website or make an appointment with our professional team to explore how to create the greatest value for your project and jointly reach new industry heights!