Knowledge

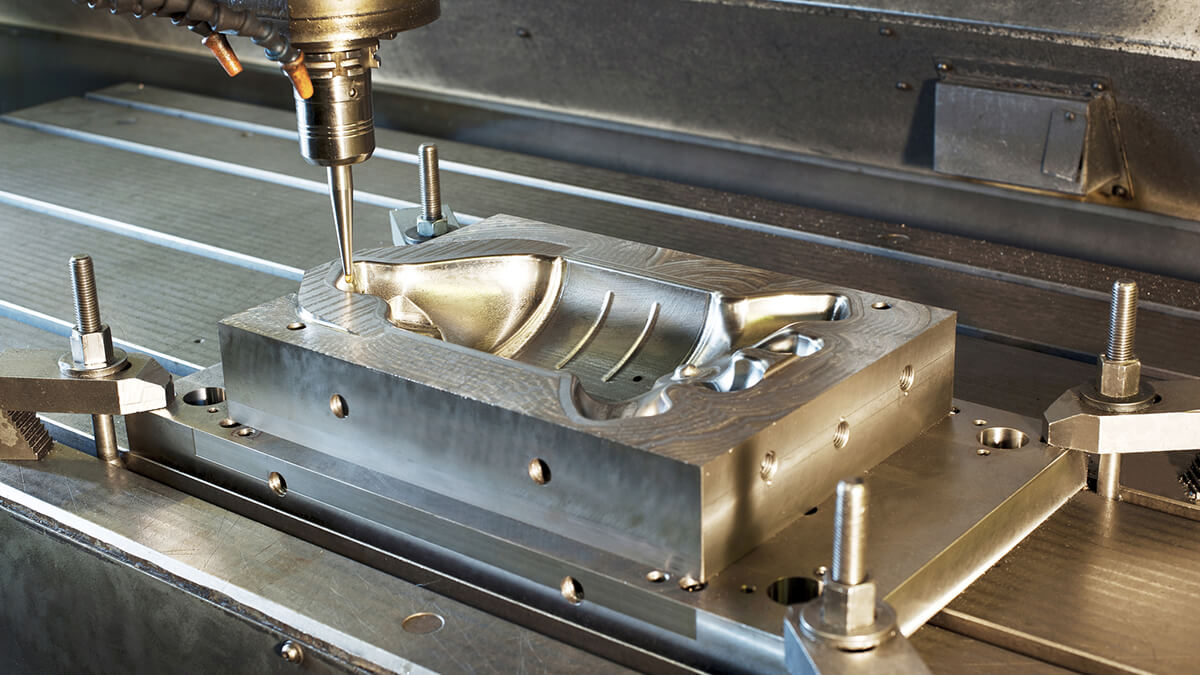

Stamping is a process in which thin walled metal parts are shaped by punches and dies.

2020-05-28 09:40:25

It is a metal cutting processing equipment. The rocker arm can be rotated and lifted around the column. The spindle box is a horizontally-moving drilling machine on the rocker arm.

2020-05-26 11:33:24

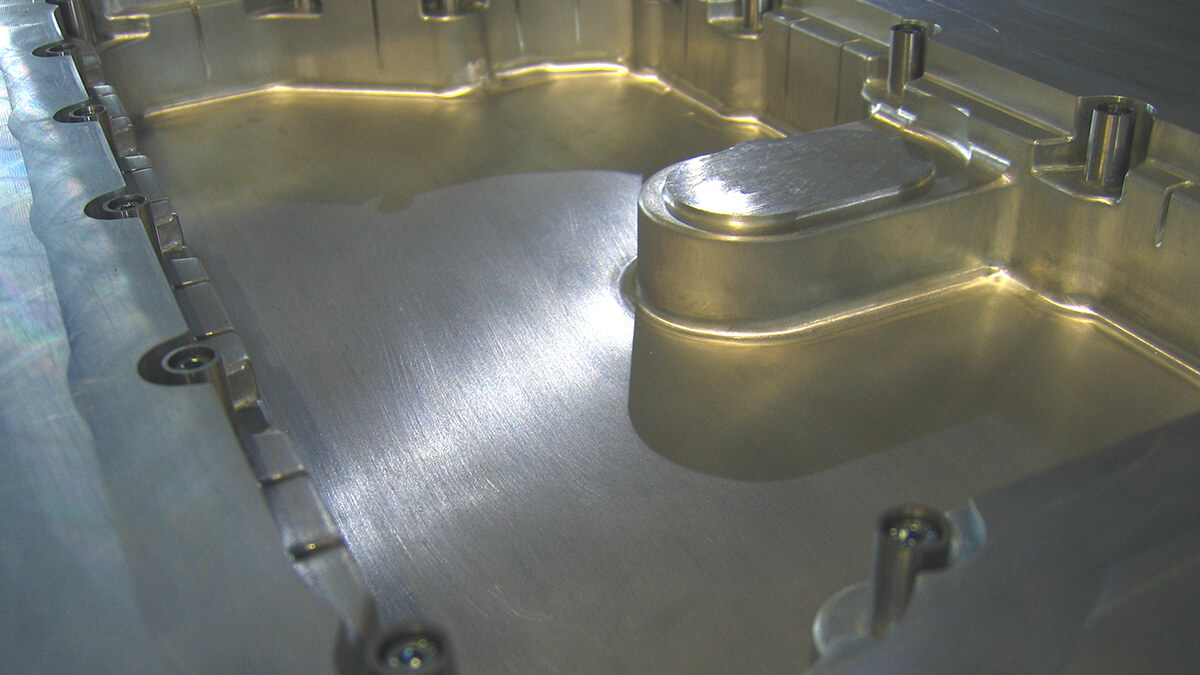

Die casting, or pressure casting, is a metal casting process characterized by the use of mold cavities to apply high pressure to the molten metal.

2020-05-22 10:12:47

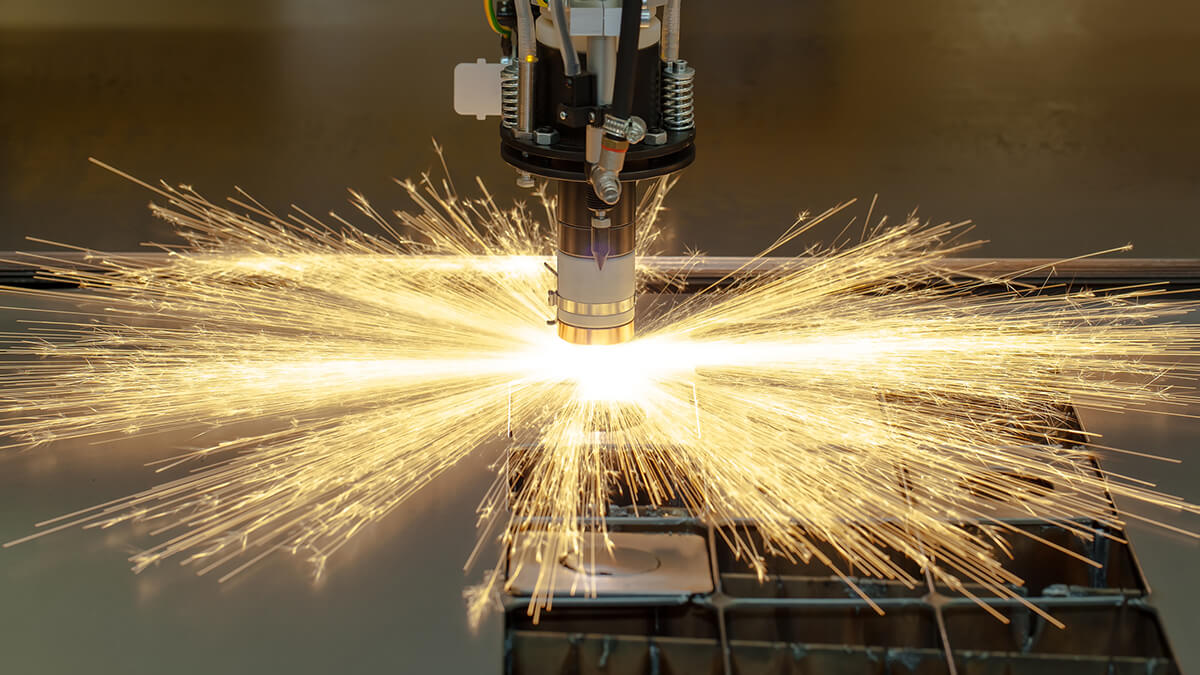

The principle of electrical discharge machining is simply a thermal processing method that converts electrical energy into heat energy of the work piece to quickly melt the work piece.

2020-05-20 09:17:50

A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting. There are various grinding machine types, each with a different purpose.

2020-05-19 09:44:27

A shaper is a type of machine tool that uses the linear relative motion between the workpiece and a single-point cutting tool to machine a linear toolpath. Its cut is analogous to that of a lathe, except that it is (archetypally) linear instead of helical.

2020-05-18 11:00:27

Computer numerical control (CNC) turning is a subtractive machining process where a cutting tool is placed against a spinning piece to take material off. This is usually done with a CNC lathe or turning center which cuts the material including wood, metal, and plastic. This article will cover the different types of CNC lathes, their components, and which type you could use for your next project.

2020-05-14 09:25:28

The lathe is the earliest working mother machine. Most of the circular parts are processed to make longitudinal or horizontal movements, and the rotating workpiece fixed on the chuck is cut to change its appearance and shape, making it a practical product.

2020-05-13 15:33:09

Lathes are machine tools that use turning tools to turn rotating workpieces. On the lathe, drills, reamers, reamers, taps, die and knurling tools can also be used for corresponding processing. Lathes are mainly used for processing shafts, disks, sleeves and other workpieces with rotating surfaces. They are the most widely used machine tools in machinery manufacturing and repair plants.

2020-05-12 17:25:14

It is inevitable that there will be some defects in the reprocessing process of metal-related mechanical equipment or parts. Therefore, the surface processing procedure of the last item is very important, and the function of surface beautification and protection is carried out, thereby improving the performance of metal parts and avoiding rust.

2020-05-12 16:45:12

Hot Topic

Agree