Insights

As most of the world still struggles with the coronavirus pandemic, China is showing once again that a fast economic rebound is possible when the virus is brought firmly under control.

2020-10-19 13:02:44

Disruptive technology is overturning the digital transformation of the automotive supply chain. The recent COVID-19 epidemic has hit the global auto market. The demand for transformation within the industry has increased. The integration of technology applications and electric vehicles will become the future development trend.

2020-10-16 16:34:33

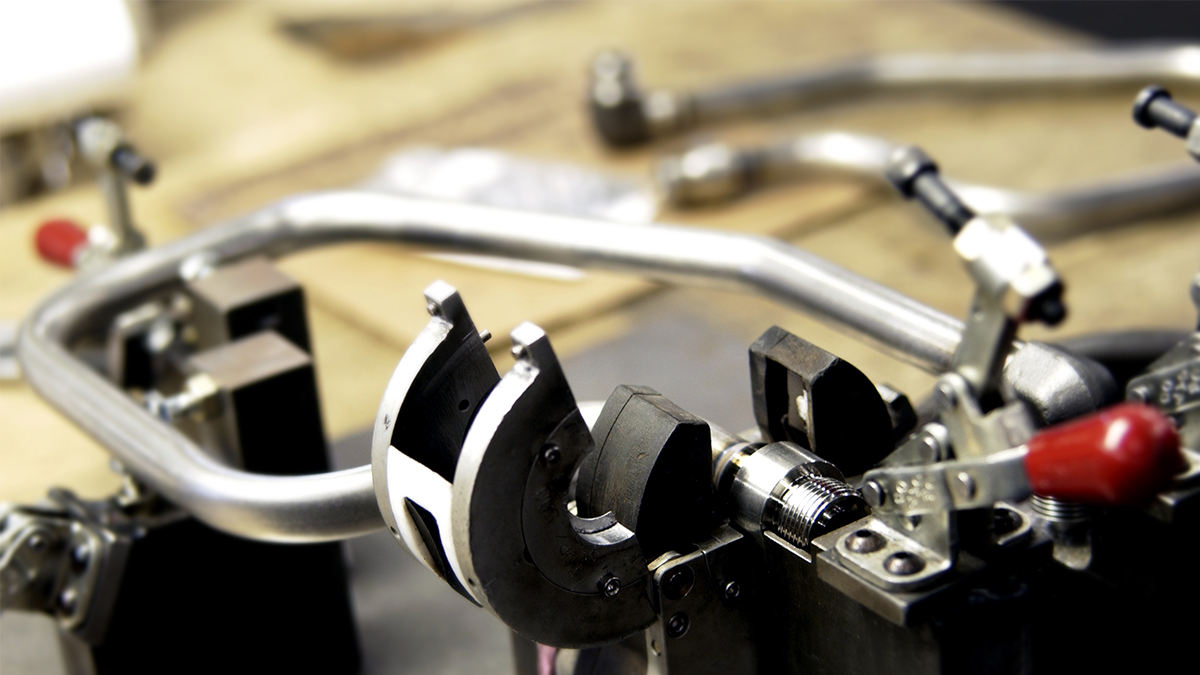

The discipline of tooling design is fundamental to manufacturing. The cost of manufacturing and of the end product depends heavily upon tool design.

2020-10-16 14:42:42

In 2020, Taiwan manufacturing output will decline by about 5%, but the semiconductor industry will maintain positive growth. Semiconductor refers to a material whose conductivity can be controlled. The upstream of the semiconductor industry chain is IP and IC design, the midstream is IC, wafer, mask or chemical manufacturing, and the downstream is the packaging and testing industry.

2020-10-13 15:20:30

Metal stamping refers to the use of the power of punching machinery and the use of molds as metal plate forming tools to produce punching separation or plastic deformation effects to achieve the production technology of parts in terms of size, shape, and performance requirements.

2020-10-05 11:32:57

A civil aircraft flying in the sky has Taiwan-made parts in the 90s; many international airlines have aircraft that have been modified and repaired by Taiwan. Taiwan aerospace industry is booming. With the next 20 years, there will be a global aerospace business opportunity of US$6 trillion.

2020-09-28 14:04:41

In response to the development of international industry demand, the laser industry and technology have begun to develop towards 5G semiconductors and smart vehicle process requirements. Taiwan’s laser industry has developed for many years and has a solid foundation, but to continue to keep up with the international pace, the need for independent laser technology step up.

2020-09-28 11:18:01

Plastic molding processing technology has been widely used in the production of many high-tech products, such as auto parts, 3C electronic products, connectors, displays, mobile phones, plastic optical lenses, biomedical application products, and general daily necessities, etc. With the trend of diversification of product usage and variability in functional requirements, plastic molding processing technology is booming day by day.

2020-09-25 17:24:51

The COVID-19 caused a great catastrophe for mankind and suffered heavy losses to the global economy and politics. How to find a model that can sustain economic life and still be able to complete work and life is the biggest challenge of life at this stage. It also urges the industry to more actively move towards the development trend of smart unmanned factories, reduce clustering and contact, introduce unmanned factory technology, and improve production efficiency and control efficiency.

2020-09-14 11:20:11

If you own a manual or CNC lathe, or if you are thinking about buying your first lathe, you may think about what types of the lathe are more suitable for you.

2020-09-11 13:33:08

Hot Topic

Agree