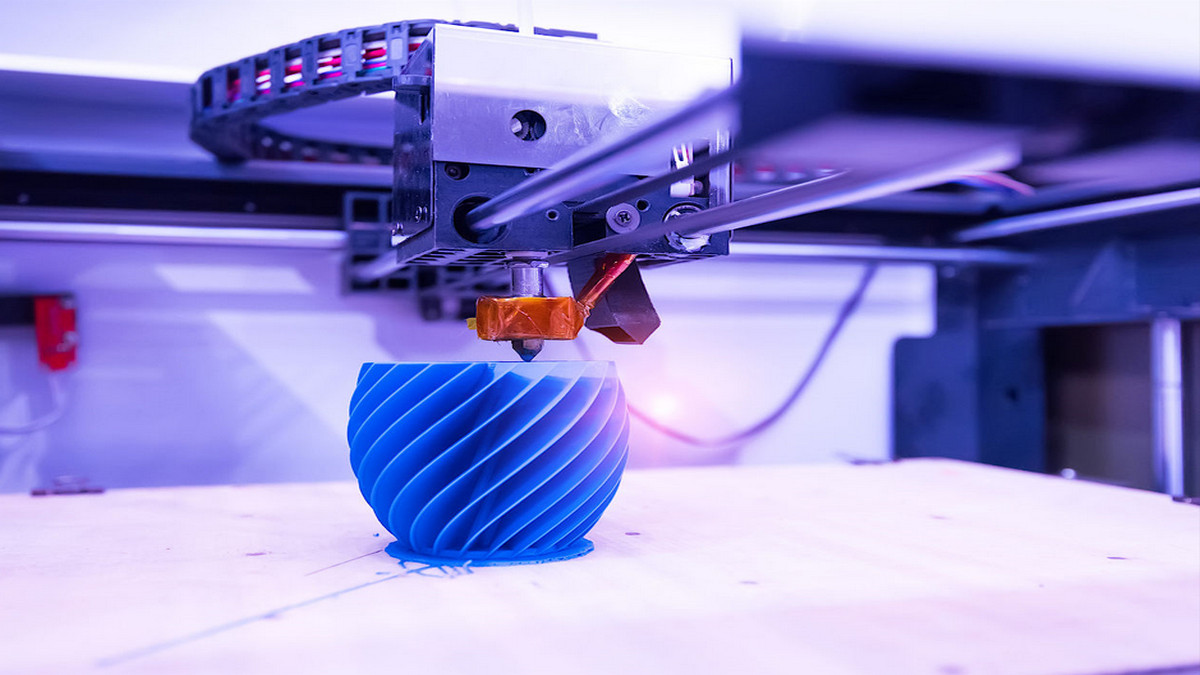

The technology for 3D printing of medical materials has soared. The new technique "Layered Manufacturing Technology", also known as 3D printing, which uses a layer-by-layer additive method to build products, has become popular in recent years. With the rapid advancement of 3D printing technology, the market for 3D printed medical materials has grown significantly.

The new wave of 3D printing has become popular in the medical field, and is being used in dentistry, orthopedics, and surgery

In 2021, as a result of the COVID-19 pandemic and the US-China trade war, as well as the international net-zero carbon emissions issue, and China's power rationing crisis, all industries have been affected. The global medical device market size in 2020 was US$427.3 billion. In 2021 it grew to US$437.7 billion and is expected to reach US$491.4 billion in 2023.

Looking back at the international medical equipment industry in 2020, the COVID-19 pandemic rapidly impacted all parts of the world, and the demand for medical equipment was greatly affected. Rapid development of precision medicine was promoted. How well enterprises transformed their business models to adapt to change was a major factor in their success.

At the same time, the aging of the global population has continued to drive up the demand for medical care. Countries are actively seeking more efficient medical solutions, promoting the development of technologies such as precision health and digital medicine to improve medical care. The goal is to improve health, reduce disease, and prolong life expectancy.

During the pandemic humans gradually established ways of coexisting with the virus. The management of the pandemic and the treatment of infection drove developments in medicine and medical technology. The aging population is still an important issue in medical technology and telemedicine has brought great changes in medical services.

The global market for 3D printing of medical equipment reached US$2.11 billion in 2020, and grew to US$2.39 billion in 2021. It is expected to reach US$5.08 billion by 2026 at a compound annual growth rate of 16.3%.

However, in 2020, the COVID-19 as the pandemic swept the world, non-emergency and elective surgeries at outpatient clinics were often postponed or cancelled. Many dental clinics were also closed, which greatly affected the sales and revenue of products and services based on 3D dental printing.

With the rebounding demand for medical services, there has been a shortage of medical supplies. With the severe shortage of medical equipment, the 3D printing industry has been able to take advantage of its rapid prototyping, online shared design and decentralized production to produce medical-grade printed materials. 3D printing can alleviate the urgent need for medical supplies, and also demonstrate the production flexibility and diversified manufacturing possibilities of 3D printed medical materials.

It is expected that after the epidemic has eased and people's medical treatment returns to normal, the global 3D printing medical equipment market will grow rapidly, doubling from US$2.39 billion in 2021 to US$5.08 billion in 2026. It is recommended to invest in product development to provide integrated products and services. In addition to accelerating the expansion of the existing field of bone and dental printing, we are optimistic about the future of smart care and cancer treatment. Emerging printing technologies such as biosensing devices and tissue engineering will also be developed. Layout of future potential markets.

.jpg)