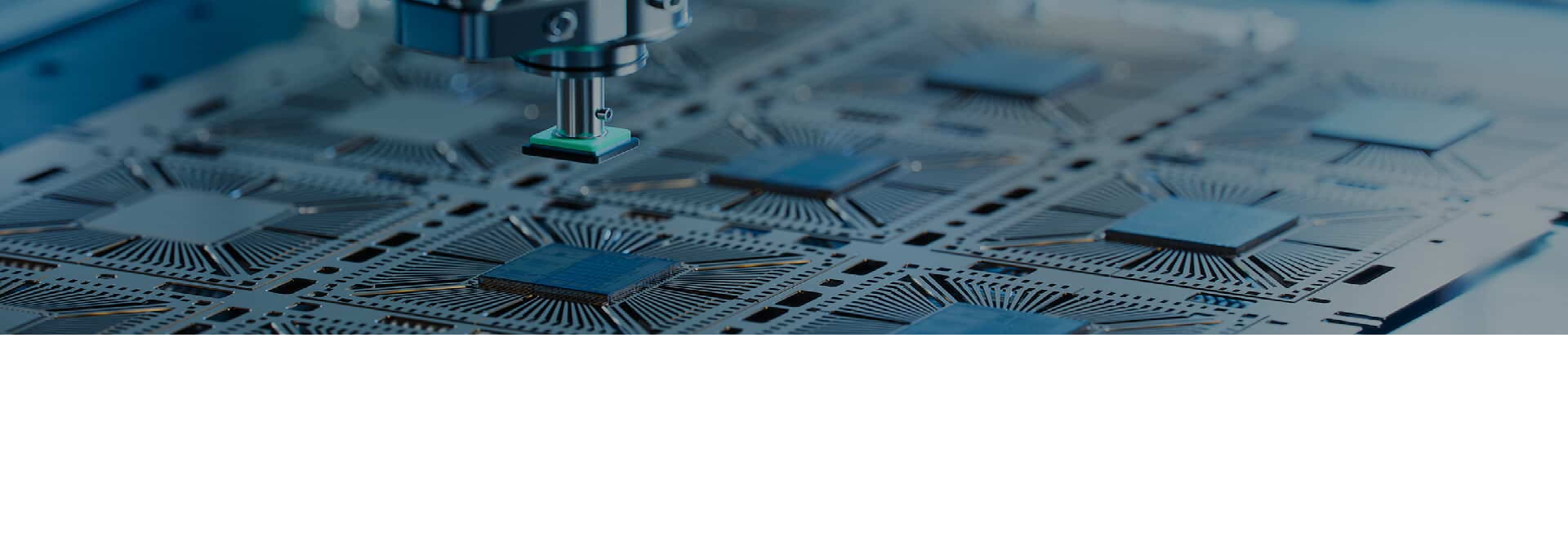

The Tech Industry Is Evolving Toward High Precision, High Speed, and Automation. As high-tech manufacturing advances, especially in sectors like semiconductors, optics, medical parts, and new energy components, the need for high-precision machining and automation continues to grow. These industries demand exceptional dimensional accuracy and machining stability to ensure product reliability and system performance. Modern society's growing reliance on technology fuels increasing demand for everything from consumer electronics to industrial-grade systems. This drives manufacturers to adopt faster, more efficient, and smarter solutions—requiring machining centers that can meet short lead times, flexible production volumes, and tight machining tolerances. Traditional models often struggle under the pressure of today’s precision-driven production requirements.

Small Double-Column High-Speed Machine Centers: The New Standard in Precision Machining

To meet these evolving demands, compact double-column machining centers—also known as gantry-type high-speed machining centers—have emerged as the next-generation solution in advanced manufacturing. Featuring a rigid bed structure, high-speed spindles, and rapid axis movement, these machines are specifically engineered for:

- Precision mold machining

- Semiconductor component manufacturing

- Optical and medical part production

- High-precision graphite and ceramic applications

These compact systems deliver the perfect balance of accuracy, thermal stability, and production efficiency, making them ideal for manufacturers pursuing high-performance machining in limited spaces.

Small Double-Column High-Speed Machine Centers: The New Standard in Precision Machining

In many modern machining environments, full-scale gantry machines are often excessive for tasks that demand finesse over force. Instead, compact CNC machining centers offer superior advantages in terms of spatial efficiency, energy savings, and high-speed responsiveness. Their monolithic casting base enhances vibration resistance, while three-axis direct drive systems enable smoother acceleration and superior motion control—resulting in unmatched precision and consistency.

Why Choose Compact Over Conventional Gantry Machines

In many modern machining environments, full-scale gantry machines are often excessive for tasks that demand finesse over force. Instead, compact CNC machining centers offer superior advantages in terms of spatial efficiency, energy savings, and high-speed responsiveness. Their monolithic casting base enhances vibration resistance, while three-axis direct drive systems enable smoother acceleration and superior motion control—resulting in unmatched precision and consistency.

SISTER Machine : Your Trusted Partner in High‑Precision Machining

As a prominent CNC machine tool manufacturer in Taiwan,SISTER Machine Technology Co.,Ltd. has been pushing the boundaries of high-speed, high-precision machining since 2006. Their compact double-column machining center series—including the SD600, SD600 5-axis, and SD1000—are built for the world’s most demanding applications in semiconductors, mold-making, and optical manufacturing.

Precision × Speed × Stability: SISTER Delivers the Ultimate Platform for Advanced Manufacturing

- Rigid One-Piece Bed Structure

A monolithic casting base enhances vibration resistance and machining accuracy during high-speed operation.

- Three-Axis Direct-Drive System

Eliminates torque loss, enabling faster, more responsive motion with greater precision—ideal for ultra-precision machining.

- High-Speed Spindle for Versatile Materials

With speeds up to 24,000 rpm, SISTER machines handle materials like aluminum, graphite, and engineering plastics with ease.

- Intelligent Thermal Stability Control

An advanced thermal compensation system reduces distortion from temperature fluctuation, preserving dimensional consistency throughout extended runs.

- Automation and Safety Options

Machines include spindle cooling, coolant systems, tool measurement, air blowers, and comply with CE certification. 5-axis options are available.

The Future of Precision Starts with the Right Platform

In today’s advanced manufacturing landscape, choosing the right machining platform is essential to staying competitive. It’s no longer just about boosting productivity—it’s about achieving uncompromising quality, repeatability, and operational intelligence. SISTER’s compact double-column high-speed machining centers provide the gateway to ultra-precision, smart automation, and sustainable growth for the next generation of tech-focused manufacturers.

More info:SISTER-CNC