CNC (Computer Numerical Control) machine tools are automated devices that control machining processes through computer programming. Known for their high efficiency, precision, and stability, they are widely used across industries such as aerospace, automotive, mold making, electronics, medical, and energy. With the rise of Industry 4.0 and smart manufacturing, CNC technology continues to evolve toward multi-axis machining, intelligent control, remote monitoring, and integrated processes. This widespread adoption not only enhances manufacturing performance but also reshapes the workforce, shifting traditional manual skills toward digital operation and system integration—bringing greater production flexibility and competitiveness to businesses.

What is a CNC Machine Tool?

CNC (Computer Numerical Control) machine tools are high-efficiency systems that automate machining processes through computer programming. Compared to traditional manual operations, CNC machines offer significant improvements in efficiency, stability, and precision, while greatly reducing the risk of human error.

With digital controls, even beginners can quickly learn to operate the machines, easing the reliance on highly skilled labor. This not only helps companies manage labor costs more effectively but also increases overall production flexibility and adaptability.

Common Types of Machine Tools and Their Machining Characteristics

There are many types of machining tools commonly used today. Based on their working principles and applications, they can be broadly categorized as follows:

- Milling Machine:

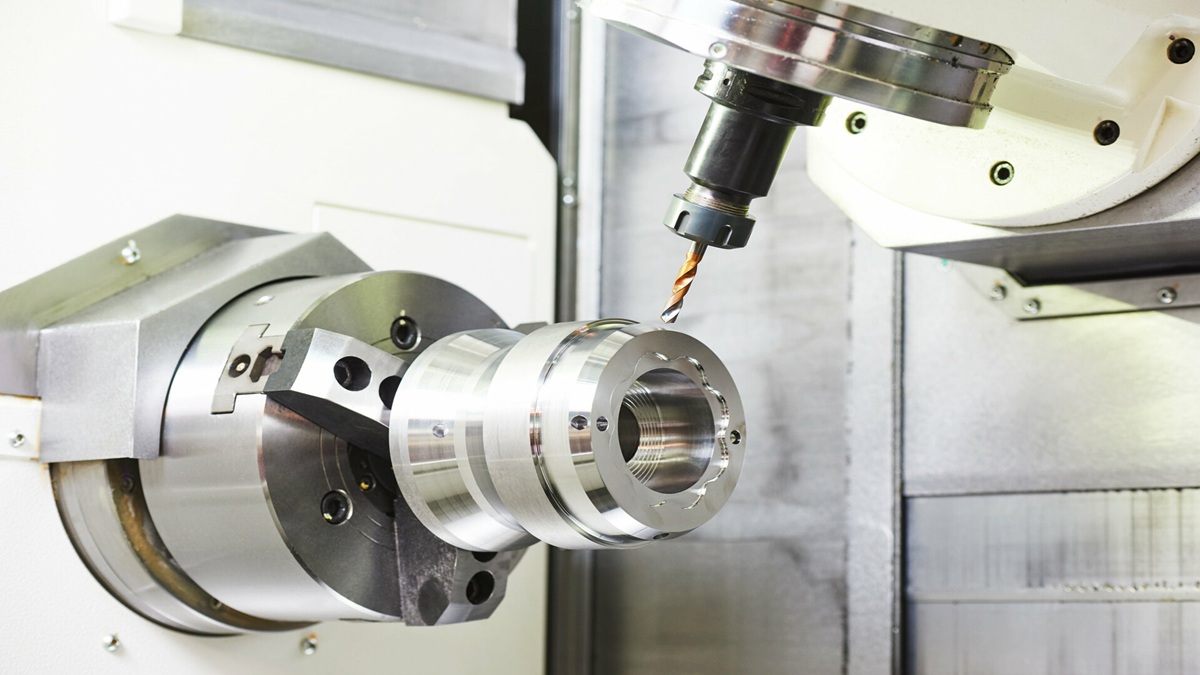

Uses rotating cutting tools to remove material, suitable for processing flat surfaces, slots, holes, and complex contours. Widely used across industries due to its versatility.

- Lathe Machine:

Rotates the workpiece while a stationary cutting tool shapes it. Ideal for cylindrical parts such as shafts, threads, and disk-like components.

- Drilling Machine:

Specializes in hole-making with greater precision than traditional drilling. Often supports automatic tool changes and repeated multi-hole operations.

- Laser Cutting Machine:

Uses a high-energy-density laser beam to precisely cut metals or plastics. Delivers fine cuts with clean edges and excellent surface quality.

- Plasma Cutting Machine:

Employs high-temperature ionized gas to create a high-speed thermal stream, making it suitable for cutting thick metal plates.

- Water Jet Cutting Machine:

Cuts materials using a high-pressure water stream mixed with abrasives. A cold-cutting process that is ideal for heat-sensitive materials like glass, stone, and plastic.

- Electrical Discharge Machine (EDM):

Removes metal using electrical discharges (sparks), allowing precise machining of hard materials or complex internal geometries. Commonly used in mold-making and high-precision components.

- Grinder:

Utilizes grinding wheels or stones to achieve high dimensional accuracy and fine surface finishes. Often used for bearings, shafts, and other precision parts.

Any machine equipped with computer programming control that can automate these machining processes is collectively referred to as a CNC machine. These machines integrate traditional machining techniques with modern digital control systems, forming a core foundation of smart manufacturing.

Applications of CNC Machine Tools

Virtually all industries that once relied on traditional machining can now be served by CNC machine tools, making their applications remarkably broad.

From the aerospace sector, where precision components must meet the highest standards, to the automotive industry, where critical parts like engines and transmissions demand consistency and accuracy, CNC machines have proven highly capable. In the mold-making industry, they handle the complex contours and fine details required for intricate surface designs with ease.

Moreover, CNC technology excels in producing miniature components in the electronics sector, high-precision surgical instruments in the medical field, and large-scale parts essential to the energy industry. With their outstanding adaptability and machining capabilities, CNC machine tools have become an indispensable cornerstone of modern manufacturing.

Trends in CNC Technology Development

With the rapid advancement of Industry 4.0 and smart manufacturing, CNC machine tools must continuously evolve to meet the demands for higher efficiency, greater precision, and manufacturing flexibility. Current research and development focus primarily on several key areas.

First, the development of multi-axis machining technology has expanded from traditional 3-axis systems to 5-axis and even more complex configurations. This advancement allows for greater flexibility in machining processes and the ability to handle parts with more intricate surfaces.

Second, the integration of intelligent control systems using AI and machine learning algorithms enables automatic optimization of machining paths and prediction of tool wear. This not only reduces maintenance costs but also improves overall production efficiency.

At the same time, remote monitoring and early warning systems have become vital recent developments. By integrating Internet of Things (IoT) devices, companies can monitor machine status in real time, enabling remote supervision and proactive alerts, which significantly enhance production stability and maintenance effectiveness.

Finally, the development of hybrid machining centers—combining milling, turning, grinding, drilling, and other functions into a single machine—has matured. This integration minimizes workpiece handling and repeated repositioning, thereby boosting overall machining efficiency and further strengthening precision control.

The Relationship Between CNC Machine Tools and Human Resources: Changes Driven by Technological Upgrades

With continuous advancements in manufacturing technology, the widespread adoption of CNC machine tools has not only boosted production efficiency but also profoundly reshaped the workforce structure within industries.

In the past, factories heavily relied on experienced skilled technicians who used their years of accumulated touch and intuition to complete machining tasks. However, as digital machine tools gradually replace traditional equipment, product quality and output no longer depend solely on individual expertise but are instead controlled through standardized programming and equipment stability.

While this shift reduces reliance on a few expert craftsmen, it simultaneously demands that the new generation of workers possess basic digital skills and a solid understanding of system operations.

Today’s CNC operators do more than just handle machining—they need to be able to read technical drawings, write or modify machining programs, and comprehend the operational logic of the machines. In other words, traditional “craftsmanship” is evolving into “digital craftsmanship.” This transition represents a redefinition of human resources and drives upgrades in vocational education and production line management.

For companies, although the initial investment in CNC machines can be high, the long-term benefits include consistent quality, lower training barriers, and enhanced flexibility and efficiency across the entire production system.

.jpg)

.png)