The medical industry environment is rapidly changing, where technological innovation and strict regulatory management have become the twin drivers of continuous corporate growth. Cambus Corporation deeply understands the importance of international medical device regulations and the ISO 13485 quality management system, viewing rigorous compliance as a strategic cornerstone for enhancing product quality and market competitiveness. By utilizing a systematic and stringent quality management framework, Cambus successfully transforms compliance challenges into a competitive advantage, effectively helping clients increase product value and accelerate product launch.

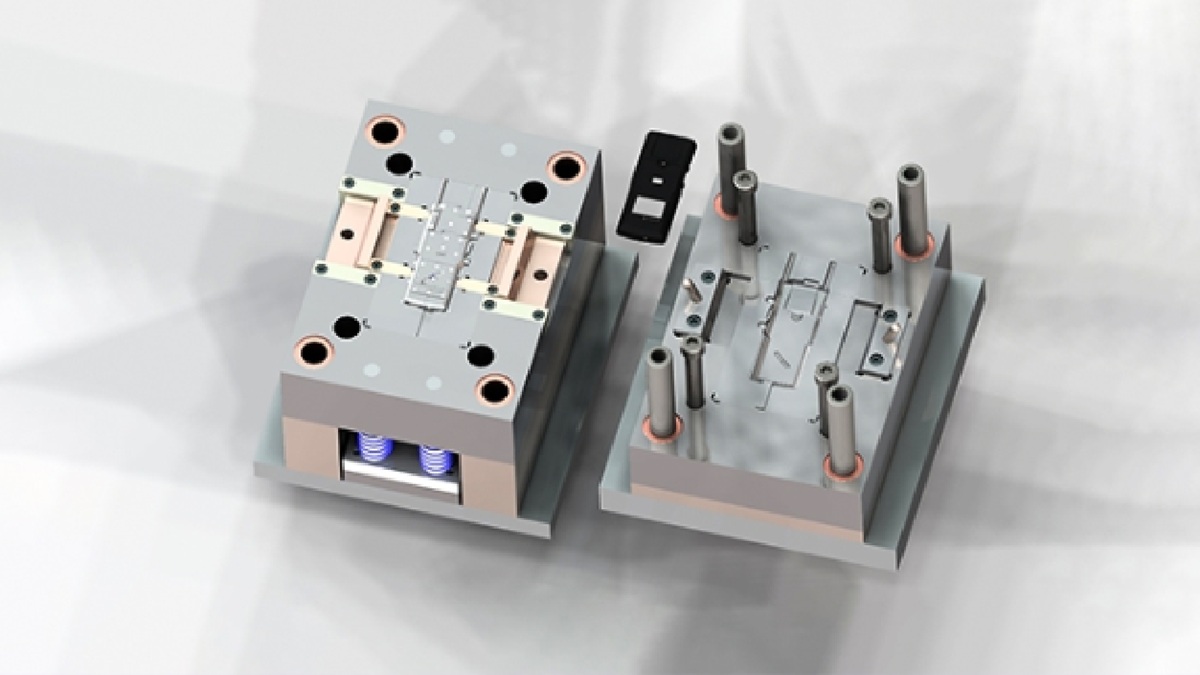

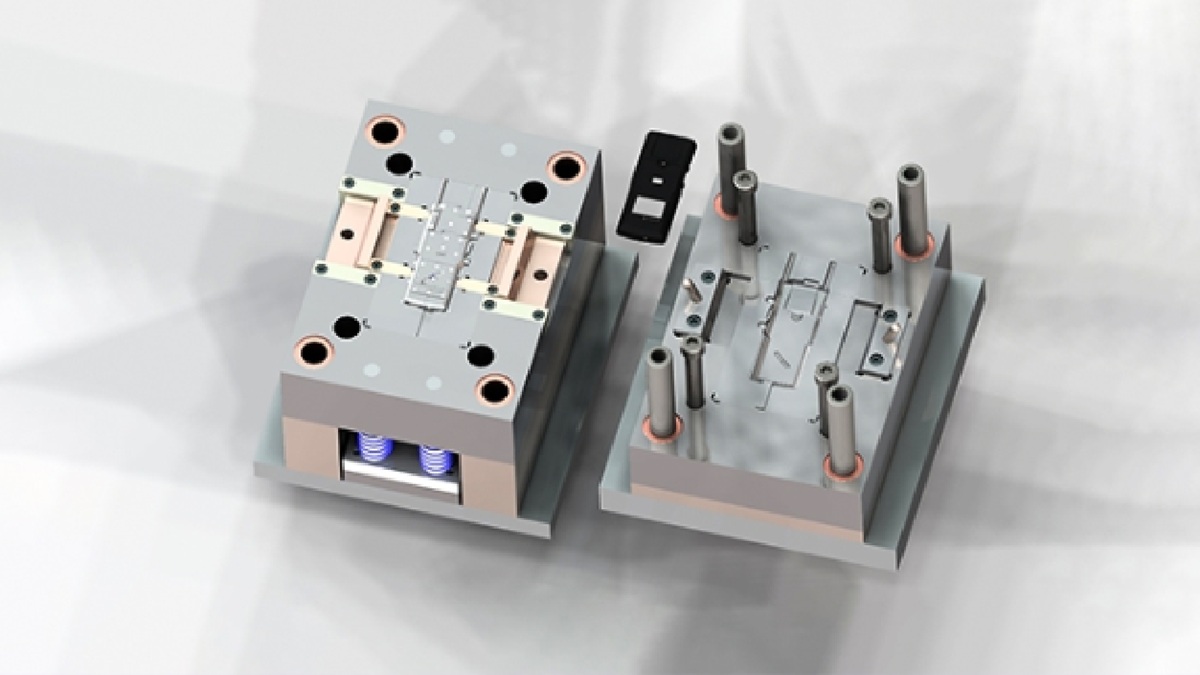

Photo by https://www.cambus-tw.com/pro-molding-tools.html

Industry Trends and Challenges

As the global medical device market continues to expand, accompanied by increasingly strict regulatory oversight, compliance has become an indispensable cornerstone for a company's survival and growth. The ISO 13485 standard focuses on quality control throughout the entire product lifecycle, covering design, manufacturing, and after-sales service, providing companies with a framework to build high quality and compliance. In the face of intense competition and strict regulations, how companies turn compliance into a unique product advantage has become a key industry issue.

The Tug-of-War Between Regulations and R&D

In the medical product R&D process, regulatory compliance often becomes a bottleneck for repeated adjustments in the later stages, easily leading to resource waste and launch delays. Cambus profoundly understands this pain point and actively promotes close cross-departmental collaboration, fully integrating regulatory reviews and risk management from the initial design phase. The product team works closely with regulatory experts to optimize design solutions through rigorous assessments of safety, biocompatibility, and electrical standard requirements, avoiding rework and effectively boosting R&D efficiency and product launch speed.

The Cambus Case Study: Making Compliance an Advantage

Cambus actively promotes the ISO 13485 quality management system, systematically integrating it into every stage of the product lifecycle, including concept initiation, design collaboration, and manufacturing processes. The Cambus engineering team works closely with clients, strictly incorporating biocompatibility, electrical safety, and material specifications into design and process standards. Taking actual application scenarios as an example, the company recommends using compliant plastic materials and simultaneously considers the product's insulation and waterproof rating during the mold design stage. This prevents rework and shortens the cycle from prototype to mass production. In the manufacturing phase, Cambus introduces a strict process control and batch tracking system, combined with automated monitoring and multiple performance tests, to ensure the stable and reliable quality of components, enhancing overall product stability and service life, reducing after-sales repair rates and costs, and bringing continuous competitive advantage to partners.

From Manufacturer to Partner, Co-creating Future Value

Cambus's successful practice offers a crucial insight to the medical industry: quality and compliance are not obstacles to innovation, but key catalysts for it. When a company can view rigorous quality management as a core competence, it can transcend the role of a traditional component manufacturer and become a solid and trustworthy strategic partner for its clients. Cambus proves through its actions that choosing a high-quality partner not only safeguards product quality but also transforms compliance challenges into a market advantage, working together to drive the innovative future of medical technology.