Insights

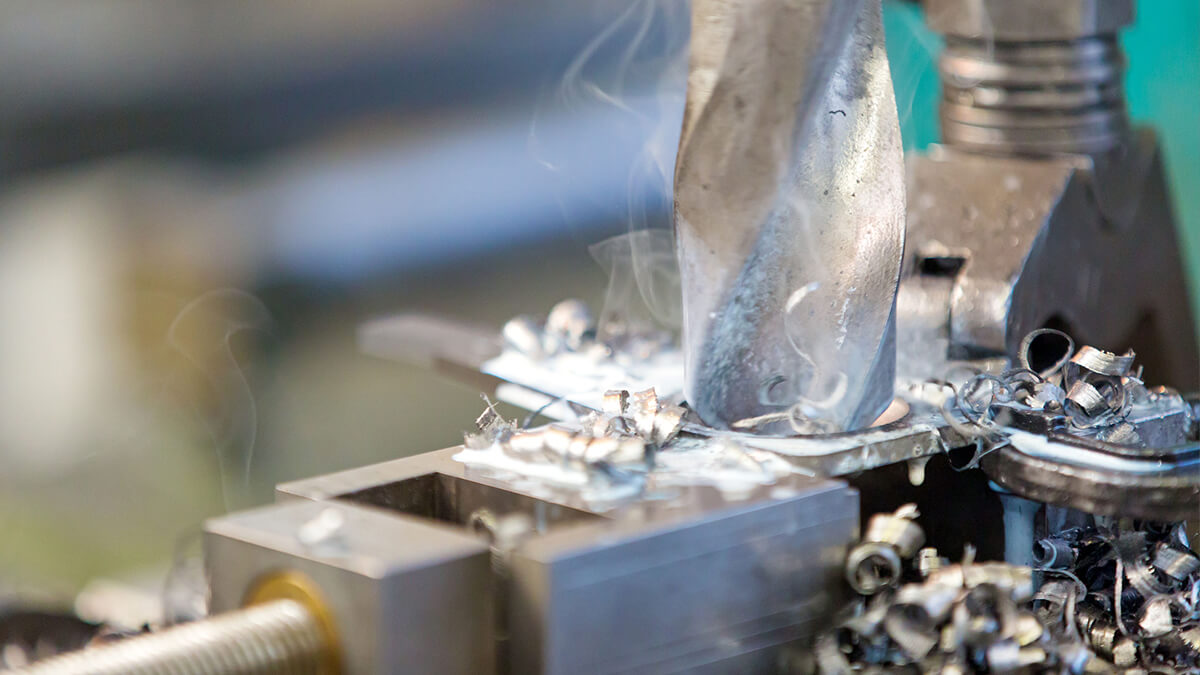

Slotting machines are reciprocating machines that are mainly used to manufacturing horizontal, vertical or flat surfaces.

2023-10-03 16:08:58

Supply chain carbon emissions are 11.4 times greater than operational carbon emissions. Therefore, if companies are to move towards net zero, the effectiveness of supply chain carbon reduction will be an important key. However, supply carbon reduction faces two major problems: inconsistent calculation methods and low data transparency.

2023-09-18 16:33:32

Due to the outbreak of COVID-19 and its rapid global spread, the global auto parts, semiconductor, and electronics industries have been exposed to highly uncertain risks. Global supply chain logistics is an issue that everyone has had to reexamine.

2023-09-18 16:28:58

With technological progress and industrial restructuring, the cement industry is actively introducing a circular economy and has become an international pioneer in net-zero carbon emissions through alternative fuels, alternative raw materials, waste heat power generation, green power development, and carbon capture technologies.

2023-09-18 16:07:05

With the pressure of international net-zero emissions and the clarion call for carbon tariffs in Europe and the United States, countries have formulated relevant policies to devote themselves to energy conservation and carbon reduction.

2023-09-18 16:02:31

The growth of the overall global biotech pharmaceutical market is slowing down. Europe and the United States have entered a mature period, and global development in the overall biotech pharmaceutical industry market has slowed down in recent years.

2023-09-18 15:52:34

Countries are actively developing heavy industries, manufacturing, and infrastructure to drive market growth, but they often pay environmental costs accordingly. Approximately 70% of global greenhouse gas emissions come from infrastructure construction and operations, such as power plants, buildings, and transportation. What will be the effect of promoting society's emphasis on low-carbon manufacturing?

2023-09-18 15:49:23

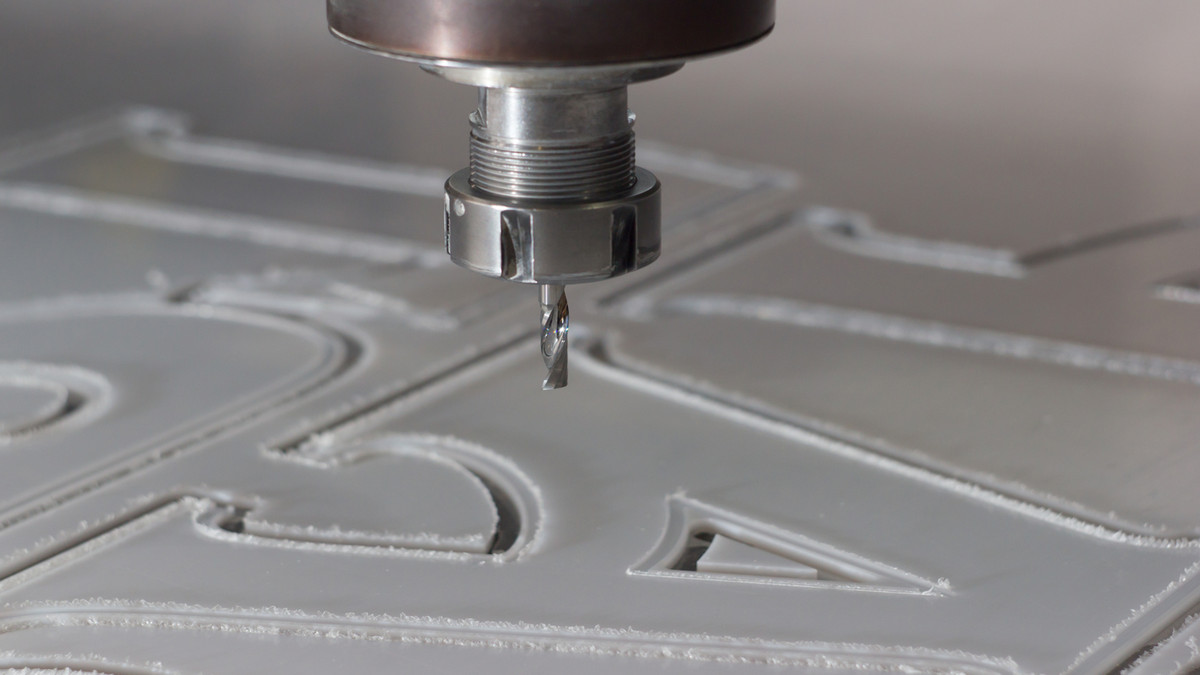

In the trend of industrial automation, motion control is a key part of it. Automating operations through machines can avoid a lot of human error, and can also speed up production efficiency and efficiency. How to make the machine act according to the command is the application category of machine motion control.

2023-09-18 15:45:29

Hyperautomation is the use of the power of multiple technologies to achieve end-to-end automation. Hyperautomation is the process of continuously integrating automation into an organization's business processes, combining advanced technologies such as robotic process automation (RPA), artificial intelligence, and machine learning to enhance the results of human work. Not only does it automate key processes, but it also builds an automation ecosystem that finds more processes that can be automated without human intervention.

2023-09-15 09:06:39

The emergence of automation has had a great impact on many industries. Many highly repetitive factory operations may restrict production capacity. With the introduction of Industry 4.0, various technologies have led to the automation of production lines, from the supplying of raw materials, to assembly, distribution, and packaging. People are taking notice of these very important developments, and this article will explore some of these new forms of automation, and the value they bring.

2023-09-15 09:52:37

Hot Topic

Agree