Slotting machines are reciprocating machines that are mainly used to manufacturing horizontal, vertical or flat surfaces.

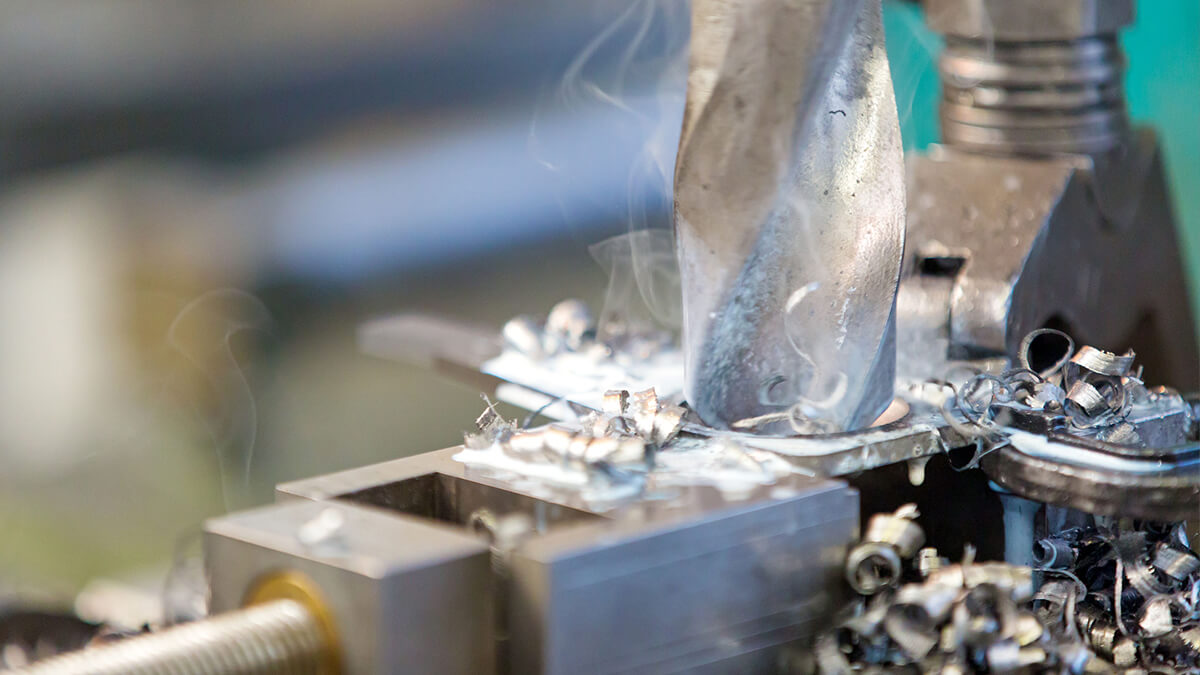

A slotting machine, also known as a slotter, is a specialized machining tool used to create slots, keyways, and other recesses in workpieces. It operates through a reciprocating cutting tool to remove material, creating precise slots or grooves in the workpiece.

Slotting machines are commonly used in manufacturing and metalworking industries for various applications, including the production of keyways, internal and external grooves, and shaping irregularly shaped parts. Their precision and versatility make them essential tools for creating intricate slots in workpieces.

A slotting machine is actually a vertical planer, and its mechanical structure principle is similar to that of a head planer. The inserting knife moves back and forth in the vertical direction as the main movement, while the processed object is intermittently moved horizontally or on a circular arc as the feed motion. The slotting machine is mainly used for cutting planes, forming surfaces and key-ways, etc., and is suitable for single or small batch production.

A Slotting Machine Can Be Divided into the Following Main Components:

- Base: The base becomes a bed or box, which can support the entire slotter.

- Cross-Slide: Install on the top of the cross-slide rail and cross-slide again.

- Handwheel: Move the table by preliminary or horizontal rotation by operating the handwheel.

- Column: The column is also a beam-column of the machine. It is made of cast iron and has a driving function. The column can be moved up and down by precision machining as a vertical object.

- Ram: Carry the slotting tool and move at right angles to the table to process the workpiece.

- Table: The table used to fix and placed the workpiece. It can be rotated in advance, horizontally or around the center to adjust to a suitable position.

The Slotting Machine Mainly Performs below Processing:

- Used to cut slots, splines key-ways for both internal and external jobs such as machining internal and external gears.

- Used for shaping internal and external forms or profiles.

- Used for works as machining concave, circular, semi-circular and convex surfaces.

- Used for machining vertical surfaces, machining angular or inclined surfaces, machining of shapes which are difficult to produce on a shaper machine and machining dies and punches.

- Used for internal machining of blind holes.

.jpg)

.png)