As industrial automation, precision machining, and sustainability reshape global manufacturing, procurement managers face mounting pressure to balance cost, reliability, and innovation. Hydraulic systems remain essential to industries ranging from machine tools and plastics to metal forming and robotics — and the hydraulic pump sits at the core of every efficient system.

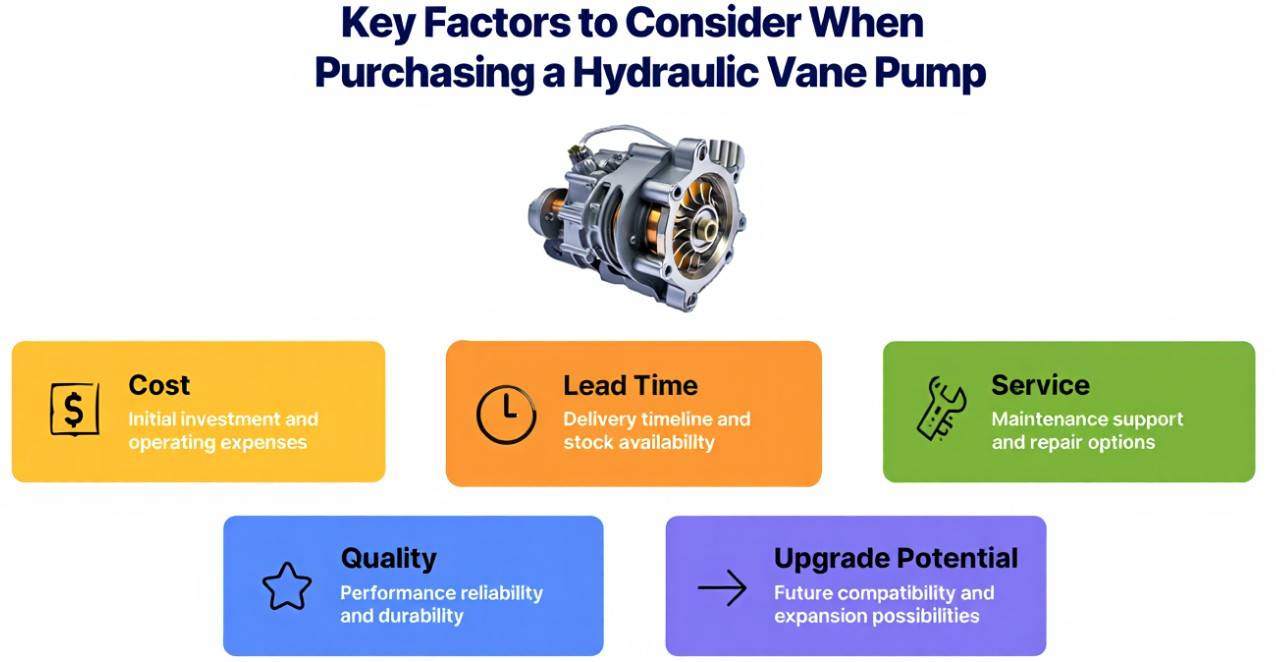

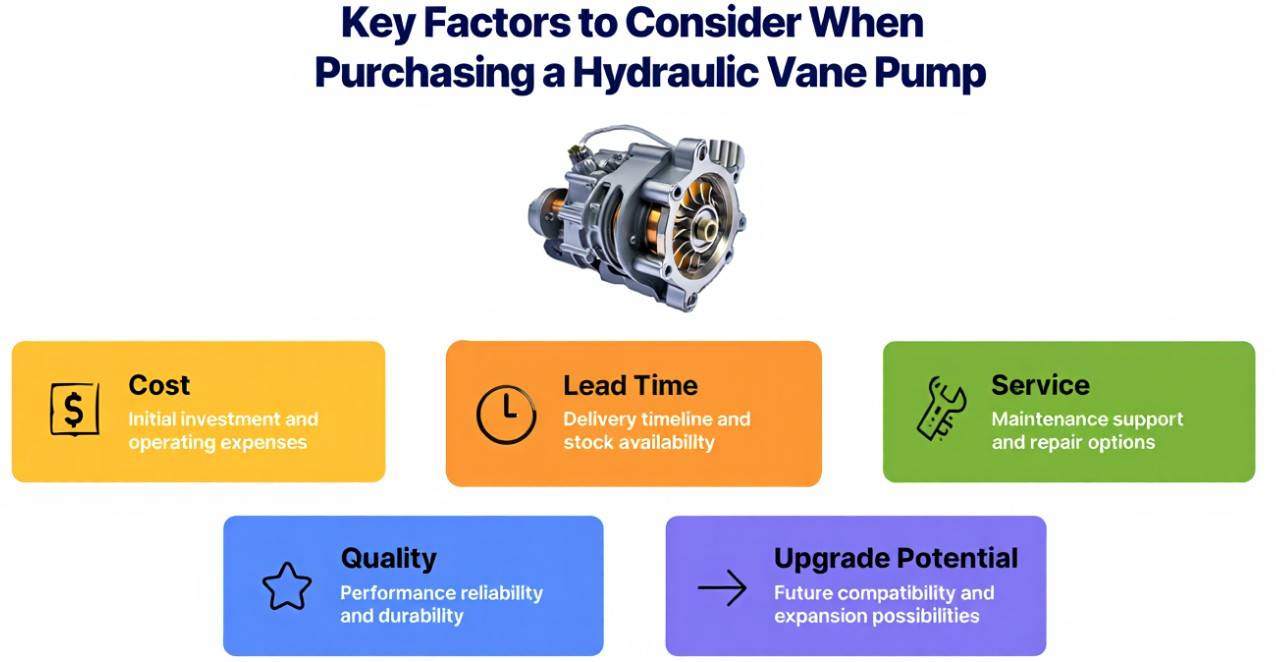

Yet, selecting the right hydraulic pump supplier has evolved from a simple purchasing process to a strategic business decision. This article examines the five key factors that leading manufacturers and OEMs now prioritize—cost, lead time, service, quality, and upgrade potential—and how companies like ANSON HYDRAULICS INDUSTRIAL CO., LTD. are redefining procurement partnerships in the B2B hydraulic sector.

1. Cost: The Shift from Price Comparison to Value Engineering

Beyond the Lowest Bid

Industrial buyers no longer evaluate cost based only on upfront pricing. According to recent procurement benchmarks, lifecycle cost—including energy efficiency, maintenance, and failure rate—has become a defining metric for hydraulic systems.

A hydraulic pump that consumes 10% less power and operates 20% longer between service intervals can yield significant savings over its lifespan. ANSON HYDRAULICS supports this value-engineering approach by integrating energy-efficient pump designs and modular components that simplify maintenance and reduce downtime.

Total Cost of Ownership (TCO) as a KPI

Forward-thinking manufacturers calculate total cost of ownership (TCO) instead of comparing unit prices. This includes spare parts availability, maintenance frequency, and warranty coverage—areas where suppliers with full-service capability, like ANSON, consistently outperform price-driven competitors.

2. Lead Time: The New Benchmark for Supply Chain Resilience

Shorter Lead Times = Greater Market Responsiveness

Global disruptions over the past few years have pushed supply chain resilience to the forefront of procurement planning. When delivery schedules tighten and production cycles accelerate, lead time reliability becomes a decisive advantage.

In Taiwan’s precision manufacturing ecosystem, ANSON HYDRAULICS has developed integrated production and logistics systems that allow agile response to global demand. This reduces bottlenecks and ensures continuity for OEM clients managing just-in-time operations.

Case Example: Machine Tool OEM Supply Stability

One CNC machine builder reported that a two-week delay in hydraulic component delivery halted production worth nearly USD 250,000. By transitioning to ANSON’s managed lead-time model, the company achieved 98% on-time delivery across multiple product lines—a powerful illustration of how supplier reliability directly impacts business continuity.

3. Service: The Strategic Advantage of Technical Partnership

From Vendor to Engineering Partner

Today’s procurement teams prioritize suppliers who can collaborate in product development, not just deliver parts. ANSON HYDRAULICS embraces this evolution with a total service solution, providing consultation, co-design, testing, and post-installation support.

This approach allows clients to optimize system integration from the earliest design phase—ensuring pumps align perfectly with power requirements, system pressure stability, and space constraints.

After-Sales Support as Risk Mitigation

Unplanned downtime remains a major cost driver in hydraulic operations. Suppliers with responsive after-sales service help mitigate this risk. ANSON’s engineers assist clients worldwide in diagnosing system issues, supplying parts rapidly, and maintaining performance benchmarks through preventive maintenance programs.

4. Quality: Why Manufacturing Precision Still Defines Brand Trust

Quality as a Competitive Currency

In an increasingly competitive industrial market, “good enough” is no longer sufficient. Hydraulic pumps are critical performance components where micron-level machining accuracy and consistent material integrity directly determine product lifespan.

ANSON HYDRAULICS’ ISO-certified facilities employ precision machining, automated inspection systems, and endurance testing to ensure consistent performance under high pressure and continuous operation.

Quality + Traceability

Every pump produced by ANSON can be traced through a complete manufacturing record—from raw material certification to final test data. This level of transparency is becoming a global expectation, especially among European and Japanese OEM partners.

5. Upgrade Potential: Building for the Next Industrial Cycle

Hydraulic Systems in the Era of Smart Manufacturing

The industrial landscape is shifting toward intelligent, data-driven production. Hydraulic systems are no exception. As automation and energy optimization converge, upgrade potential becomes a critical selection criterion.

Manufacturers increasingly demand pumps that can be retrofitted with electronic control systems, or easily integrated into IoT-enabled production lines. ANSON HYDRAULICS invests heavily in R&D to create customizable, modular pump designs compatible with evolving smart-factory technologies.

Future-Proofing Procurement Decisions

Choosing a supplier that supports future product upgrades reduces long-term investment risk. ANSON’s engineering teams provide upgrade consultations, helping clients transition smoothly to newer designs without reconfiguring entire systems—a major cost and time advantage.

Integrating Procurement Strategy and Technical Innovation

The convergence of cost, quality, and technological advancement means hydraulic pump sourcing has become a strategic pillar of operational performance. Procurement managers now evaluate suppliers not only on what they deliver today, but also on how well they can support tomorrow’s innovations.

By offering total lifecycle service—from R&D collaboration and production to after-sales maintenance—ANSON HYDRAULICS exemplifies how supplier relationships evolve into long-term value partnerships.

The ANSON HYDRAULICS Advantage

Strategic Supply Chain Reliability: Streamlined lead times and stable production cycles.

Engineering Partnership Model: Collaborative product design and OEM/ODM flexibility.

Proven Quality Assurance: ISO-certified manufacturing and 100% testing protocols.

Sustainability Commitment: Energy-efficient designs that reduce operational costs.

Global Reach: Trusted by machine tool manufacturers and hydraulic system integrators worldwide.

Looking Ahead: Defining the New Standard of Hydraulic Procurement

The next generation of hydraulic systems will demand suppliers who think beyond traditional manufacturing. As the industry moves toward energy efficiency, modularity, and data integration, the procurement mindset must evolve accordingly.

For buyers who value technical partnership, consistent performance, and long-term ROI, ANSON HYDRAULICS delivers more than components—it provides a pathway to future-ready hydraulic system solutions.

Partner with ANSON HYDRAULICS for Strategic Growth

Whether you are an OEM seeking custom pump development or a distributor looking for dependable supply, ANSON HYDRAULICS INDUSTRIAL CO., LTD. stands ready to collaborate.

Reach out today to explore how our full-cycle service model—from design to delivery—can enhance your hydraulic system performance and procurement efficiency.