- Showing results for

- Machine Tools

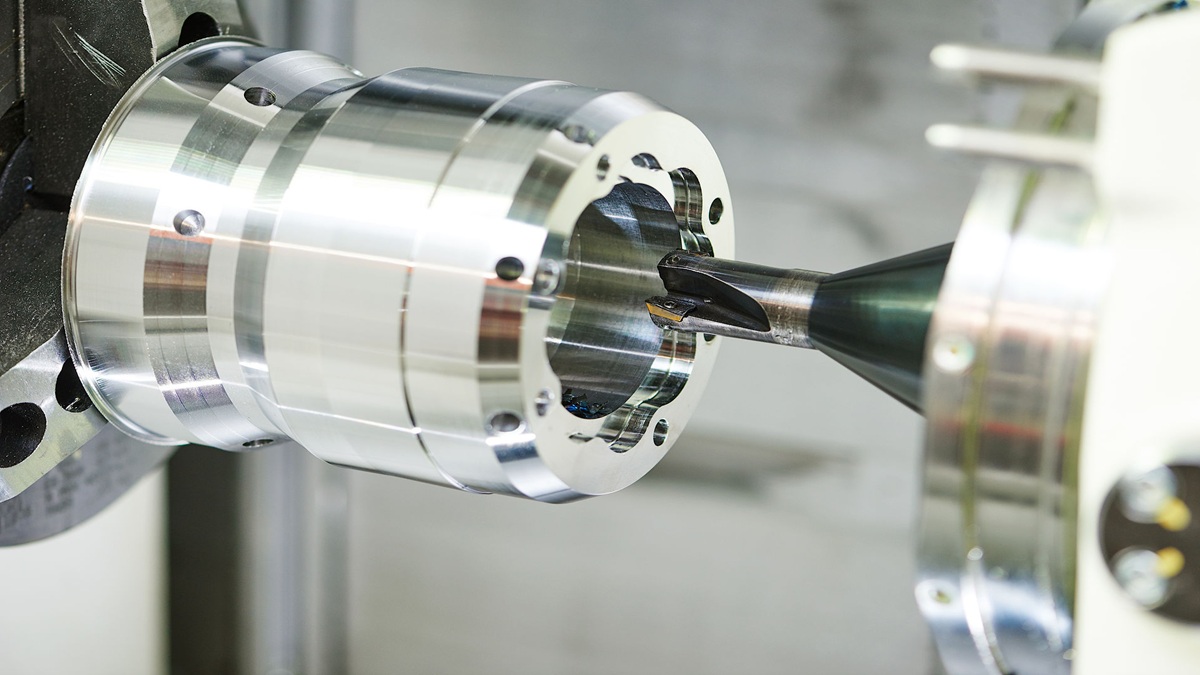

Electrical Discharge Machining (EDM) is a non-traditional machining process that removes metal through electrical sparks. Unlike conventional methods, it is not limited by material hardness and can precisely create deep cavities, micro-holes, and complex structures in hardened steel, tungsten carbide, or superalloys. The three main types of EDM include wire cutting, die-sinking, and hole drilling, which are widely applied in mold making, aerospace, automotive, and medical industries. Although EDM has a slower processing speed, works only with conductive materials, and requires consideration of electrode wear and surface treatment, its advantages in high precision, zero cutting force, and superior surface finish make it an indispensable technology in precision manufacturing. Moreover, it continues to evolve in line with the trend toward smart manufacturing.

2025-08-28 10:37:32

The global precision manufacturing industry is facing unprecedented challenges: completing complex, multi-angle workpieces within tight deadlines while maintaining stringent precision. In this environment, five-axis machining has become a critical key to boosting corporate competitiveness. TOP SDISK (Spintop Machinery Co., Ltd.) tackles this challenge head-on by leveraging industry-leading direct drive motors and cam technology to build high-speed, high-rigidity double-axis CNC rotary tables, injecting intelligence and innovation into the manufacturing sector.

2025-08-27 15:56:14

In 2025, as global manufacturing continues its rapid digital transformation, the machine tool industry is facing significant change. International buyers in aerospace, electric vehicles, and high-end electronics are increasingly prioritizing smart services and data applications over mere machining precision. Taiwan's machine tool industry is actively integrating the Internet of Things (IoT), artificial intelligence, and big data technology, expanding from traditional hardware manufacturing into the smart solutions sector. This move helps global manufacturing clients boost production efficiency and enhance equipment maintenance management. This article will delve into how Taiwan's machine tool industry is becoming an indispensable smart partner for global manufacturing, delivering sustained value.

2025-08-27 14:56:00

With the surging demand from 5G, electric vehicles, and AI computing, the multilayer ceramic capacitor (MLCC) market continues to grow, driving momentum for Taiwan’s industry. Yet, component miniaturization and concentrated production capacity pose new challenges to manufacturing processes. LONG addresses these hurdles with high-precision SMD chip coating and bevel coating technologies that break through micron-level limits while delivering coating throughput far beyond industry standards. By leveraging thin carrier plates and integrated solutions, LONG enhances both stability and efficiency in production—helping customers meet the dual challenges of miniaturization and capacity, and ultimately creating greater value for the industry.

2025-08-27 13:47:11

Since its founding in 1963, J-King International Corporation has specialized in the design and manufacturing of conveying and power transmission equipment. Under its proprietary brand JUKYO™, the company offers a diverse range of products—spanning from individual components to complete conveyor systems—providing manufacturers with one-stop solutions.

2025-08-27 11:46:45

The medical industry is experiencing rapid growth, driven by an aging population, rising chronic diseases, and technological advancements. The demand for high-precision medical devices is increasing, requiring manufacturing processes that ensure safety, reliability, and performance. Machine tools play a critical role in meeting these stringent requirements, enabling the production of complex medical instruments with exceptional accuracy.

2025-08-26 15:20:47

The global manufacturing industry is entering a new chapter of high precision and sustainability. From aerospace to advanced electronics, micron-level accuracy has become the baseline. Traditional machining methods can no longer keep up, while Electrical Discharge Machining (EDM), with its unique non-contact process, has earned the name “the invisible tool” of precision manufacturing by overcoming the limits of ultra-hard, brittle materials and complex structures. Excetek, a leading force from Taiwan, focuses on wire-cutting, sinker EDM, and small-hole EDM technologies. With innovative R&D, intelligent design, and energy-saving solutions, the company has not only achieved ISO and CE certifications but also successfully expanded into global markets—driven by its core values of innovation, precision, and service.

2025-08-26 09:39:29

Machine tools are the cornerstone of modern manufacturing, enabling precise cutting, forming, and machining of metals and other materials. During operation, these machines generate significant friction and cutting heat, which, without proper management, can lead to tool wear, workpiece deformation, and reduced machining accuracy. Lubrication and cooling systems are essential for mitigating these issues, with lubrication reducing friction and wear, and cooling dissipating heat to maintain thermal stability. Together, these systems enhance machining efficiency, extend equipment lifespan, and improve surface quality. Research indicates that effective lubrication and cooling can boost machining performance by up to 30%. This article explores the critical components—lubrication pumps, pipes, coolant pumps, and filters—while highlighting advanced techniques and future trends.

2025-08-22 16:56:48

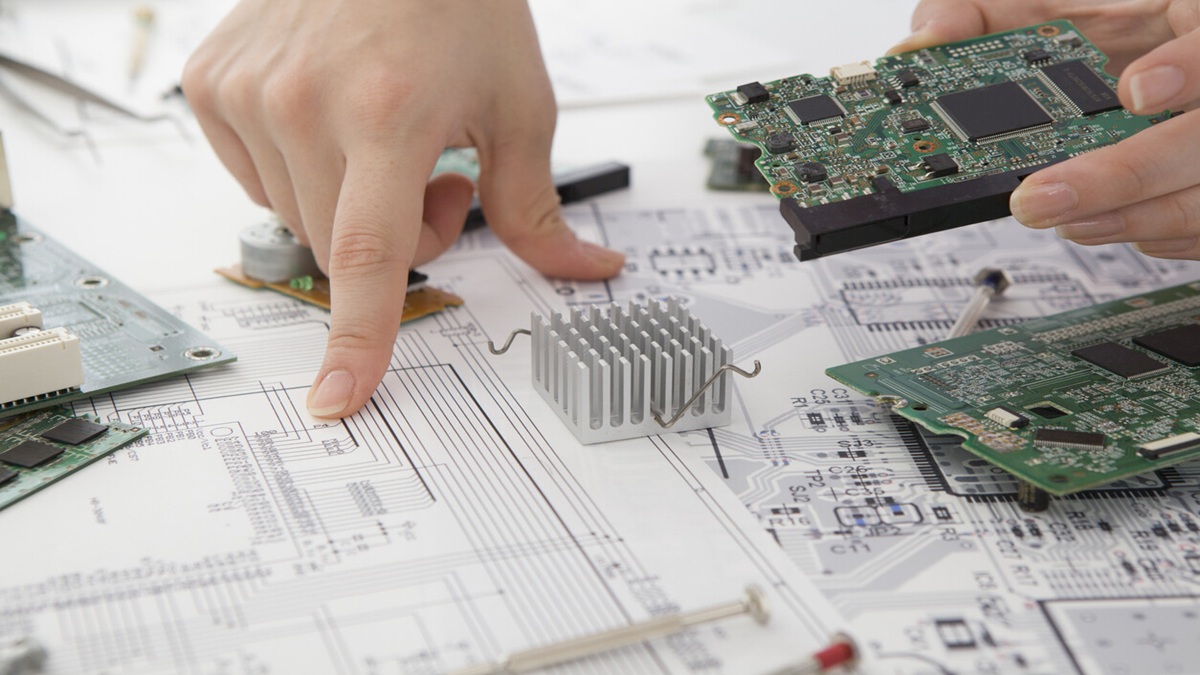

In the machine tool industry,while spindles and drive systems form the backbone of machine tools, cutting tools and clamping systems directly dictate machining precision and efficiency.Cutting tools perform the material removal, while clamping systems ensure the stable positioning of both tools and workpieces. Together, they determine machining accuracy, efficiency, and surface quality.

2025-08-22 16:15:53

With the rapid expansion of the unmanned aerial vehicle (UAV) industry, CNC (Computer Numerical Control) machines play an indispensable role in precision manufacturing. According to market research firm Grand View Research, the global drone market is expected to grow from approximately USD 40 billion in 2023 to USD 90 billion by 2030 a remarkable trajectory. CNC machining’s high-precision capabilities, from structural components and electronic parts to critical modules, can directly impact drone performance while linking the entire supply chain from raw materials to global trade.

2025-08-22 14:03:12

The global manufacturing industry is experiencing a profound transformation towards intelligence and precision. Market demands for higher precision, greater efficiency, and flexible production are increasingly urgent. Facing the challenges of high-mix, low-volume (HMLV) flexible manufacturing, enterprises critically need to balance high-precision machining with rapid responsiveness. TOP-ONE Machinery Co., Ltd. , leveraging its deep expertise in precision CNC machine tool R&D and exceptional customization capabilities, is actively engaging in this transformation. We are committed to empowering global clients to overcome transformation challenges and enhance manufacturing competitiveness through innovative solutions.

2025-08-21 12:15:18

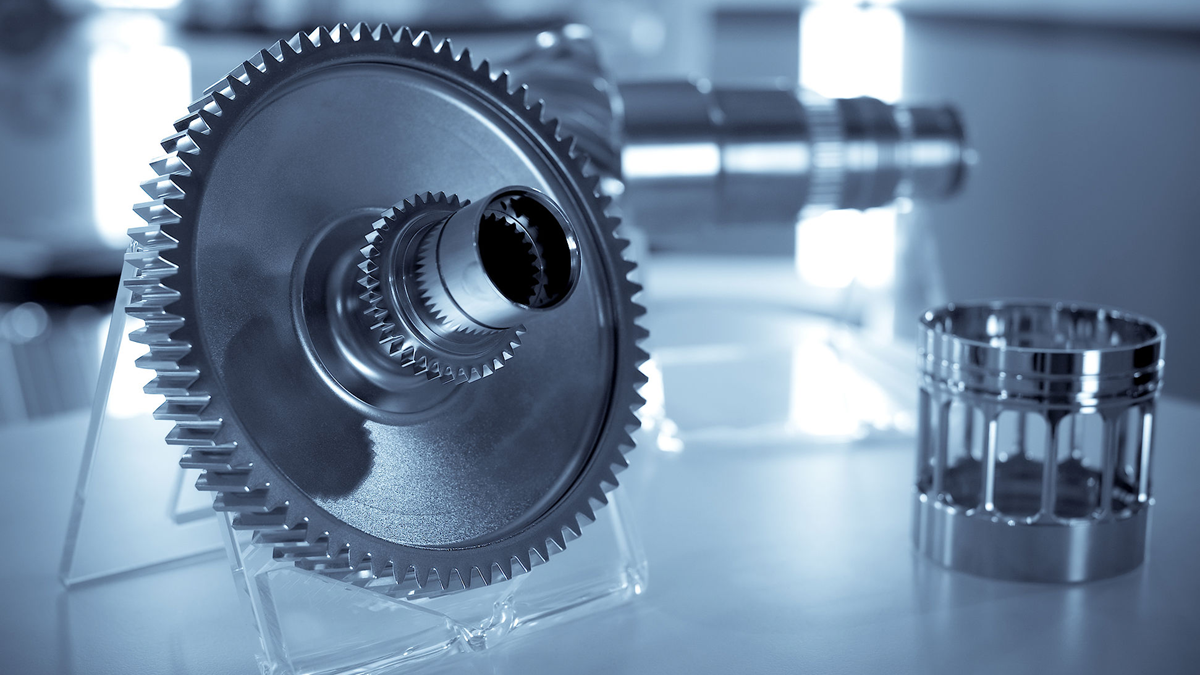

The machine tool industry, often called the “mother of industry,” is the backbone of advanced manufacturing across sectors such as automotive, electronics, aerospace, energy, and healthcare. Its value chain spans upstream components, midstream machine tool builders, and downstream application industries, all tightly interlinked. As global market demands evolve rapidly, developments at the downstream level are increasingly shaping upstream technologies and component innovations, creating a dynamic cycle of interaction.

2025-08-20 15:17:47

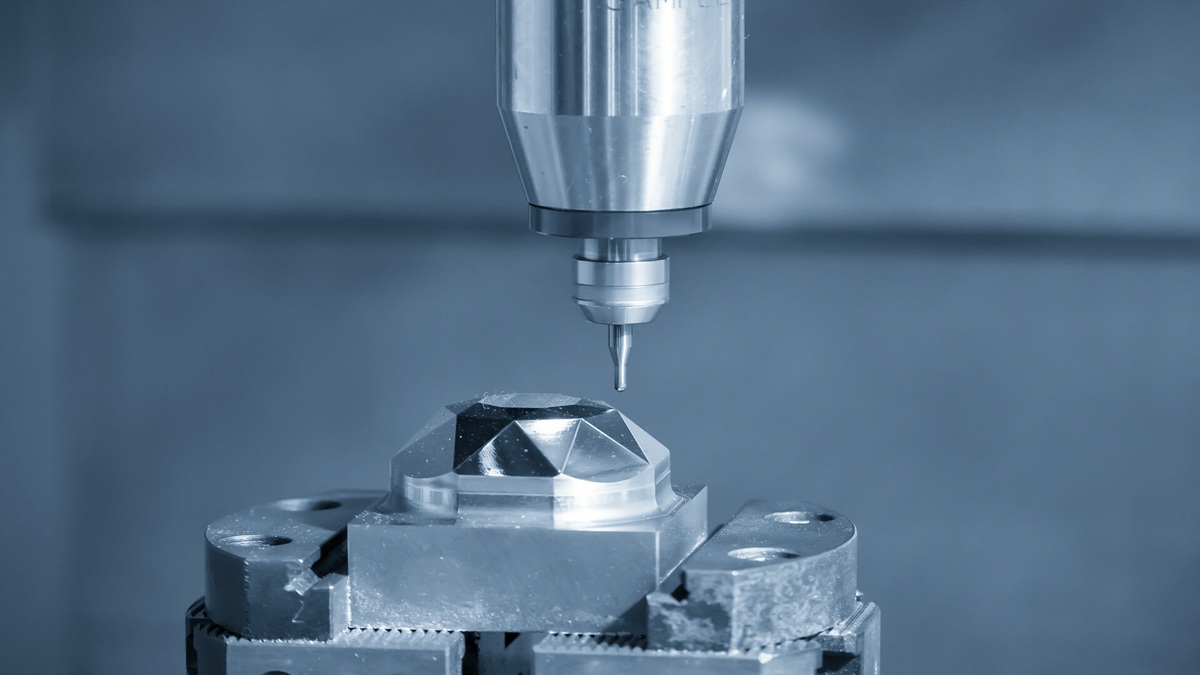

Machine tools are the cornerstone of modern manufacturing, holding an irreplaceable role in core industries such as aerospace, semiconductors, medical equipment, and renewable energy. As product designs become increasingly sophisticated and quality standards grow more stringent, traditional machining approaches are no longer sufficient. For this reason, the precise planning provided by CAD/CAM software, together with the stable high-speed cutting power of direct-drive spindles, has emerged as the foundation of high-precision machining. This article explores the synergy between software and hardware — from the digital blueprint created by CAD/CAM, to the precise execution enabled by direct-drive spindles, and finally to closed-loop control and global application trends — offering a comprehensive perspective on the technological developments shaping the machine tool industry.

2025-08-20 14:44:45

Choosing the right CNC machine tool is essential for efficient and precise manufacturing. Instead of focusing on price or brand alone, consider your machining needs, including workpiece size, complexity, material, and automation requirements. This guide helps you select the ideal CNC machine for your production goals.

2025-08-20 14:06:48

Amid the global wave of intelligent manufacturing and low-carbon transformation, Yen Shen Electric Industrial Co., Ltd. centers on motor design, drive control, and energy efficiency integration to steadily promote industrial upgrading. Upholding the philosophy of "integration, simplification, and innovation," Yen Shen focuses on synergistic design of motors and controllers, assisting industries to implement high-efficiency, low-energy-consumption intelligent power solutions, offering tangible support for energy-saving manufacturing.

2025-08-20 11:26:33

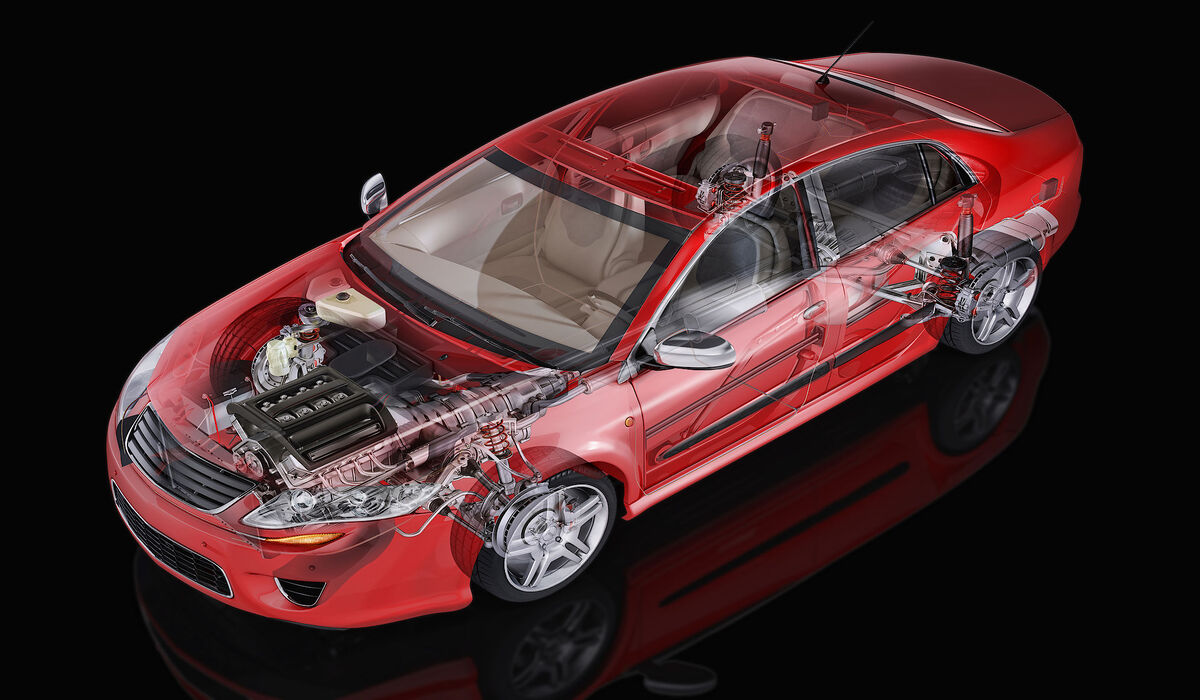

When we lightly press the accelerator and enjoy a smooth drive, there’s an invisible hero quietly at work behind the scenes: the CNC machine crafting every precise engine component. For consumers, fuel-efficient cars are often the top choice. For manufacturers, fuel efficiency is a critical factor that defines product competitiveness. Yet few realize that the journey toward efficiency doesn’t start at the gas pump—it begins with the machines that shape every micron of the engine. CNC machines are the unsung heroes making it all possible.

2025-08-19 16:28:28

With global efforts toward environmental sustainability and net-zero carbon targets accelerating, the manufacturing sector is undergoing a rapid green transformation, seeking new technologies to reduce energy consumption and minimize waste. Traditional manufacturing methods, with their high energy demands and significant waste generation, place heavy pressure on the environment. Modern turn-mill composite machining technology—through high-rigidity design and intelligent energy management systems—can effectively lower per-part processing energy consumption by around 10%, improve efficiency, and reduce equipment footprint to shrink the carbon footprint. Advanced energy-saving variable-frequency control combined with intelligent cooling and real-time process monitoring enables low-carbon manufacturing while improving yield, helping manufacturers achieve net-zero goals without compromising competitiveness. These innovations are setting a new benchmark for green, intelligent manufacturing, driving the sustainable development of global industry.

2025-08-19 11:59:13

Since establishing its base in Taichung in the early 1990s, the company has adhered to the philosophy of “Maintain and Continuously Improve.” Starting from manual and semi-automatic machines, it has progressively advanced to NC/CNC control and double-column models, building a complete surface grinding machine product line. These machines are widely applied in industries such as aerospace, automotive, mold manufacturing, semiconductors, and general machinery, offering customized solutions.

2025-08-19 09:37:01

In an era where the long-standing "efficiency-first" mindset in global manufacturing is gradually reaching its end, supply chain resilience has become an essential condition for the new normal. The COVID-19 pandemic and geopolitical turbulence have highlighted the risks of lean supply chains, which struggle to recover quickly when disrupted. In response, major enterprises are shifting towards nearshoring, supply diversification, and early-warning-based adjustment strategies. Against this backdrop, "seemingly inconspicuous" small and medium-sized components, such as bearing sleeves, are making a comeback. Their functions in stabilizing mechanical operations and extending service life are proving to be key supports in healing the fragile structures of supply chains.

2025-08-19 08:42:34

As machining technology continues to advance, the manufacturing industry’s demand for high-precision, multi-axis, and smart machining equipment is rapidly increasing. This drives machine tool manufacturers to keep innovating and optimizing their structural designs to tackle the challenges of machining complex parts. Looking ahead, industry trends will focus on enhancing machining flexibility, automation integration, and overall efficiency—key factors shaping the future of precision manufacturing.

2025-08-18 15:29:30

Agree

.jpg)