- Showing results for

- CNC Machining Center

India’s manufacturing sector is undergoing a critical transformation phase, with the rapid rise of industrial automation propelling the CNC machine tool market into a global growth hotspot. According to the latest research report by Technavio, the overall machine tool market in India is expected to increase by approximately USD 3.08 billion from 2024 to 2029, with a compound annual growth rate (CAGR) of 11.6%. In contrast, the global machine tool market CAGR is only about 5.07% (2023–2029), and the global CNC machine tool market CAGR is around 5.4% (2025–2029). India’s market growth rate is nearly twice the global average. Furthermore, supported by its large industrial base and favorable policies, India has strong potential to become a key strategic region in the global CNC machine tool market.

2025-08-12 13:53:53

Precision molds form the foundation for the quality and efficiency of plastic part molding. In today’s highly competitive manufacturing environment, the design and fabrication of molds directly impact a product’s functional performance and market competitiveness. Excellent mold development requires not only precise engineering design but also the integration of advanced machining technologies and rigorous quality control to achieve efficient and stable mass production.

2025-08-12 11:03:21

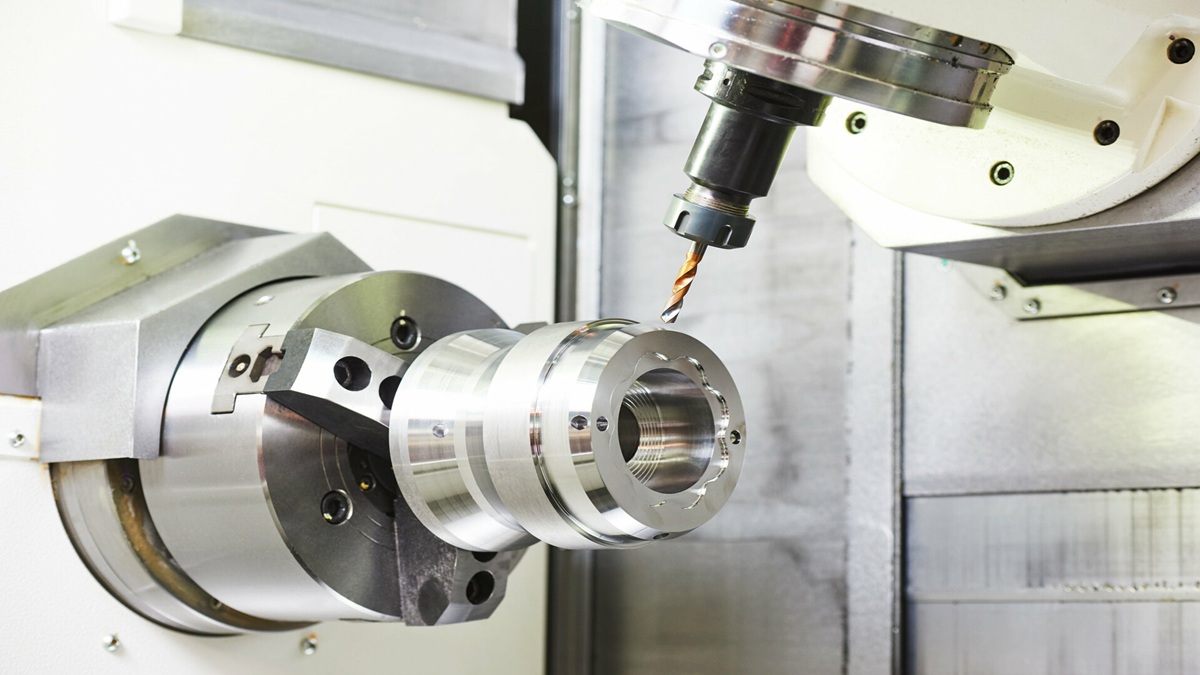

CNC (Computer Numerical Control) machine tools are automated devices that control machining processes through computer programming. Known for their high efficiency, precision, and stability, they are widely used across industries such as aerospace, automotive, mold making, electronics, medical, and energy. With the rise of Industry 4.0 and smart manufacturing, CNC technology continues to evolve toward multi-axis machining, intelligent control, remote monitoring, and integrated processes. This widespread adoption not only enhances manufacturing performance but also reshapes the workforce, shifting traditional manual skills toward digital operation and system integration—bringing greater production flexibility and competitiveness to businesses.

2025-08-08 16:05:07

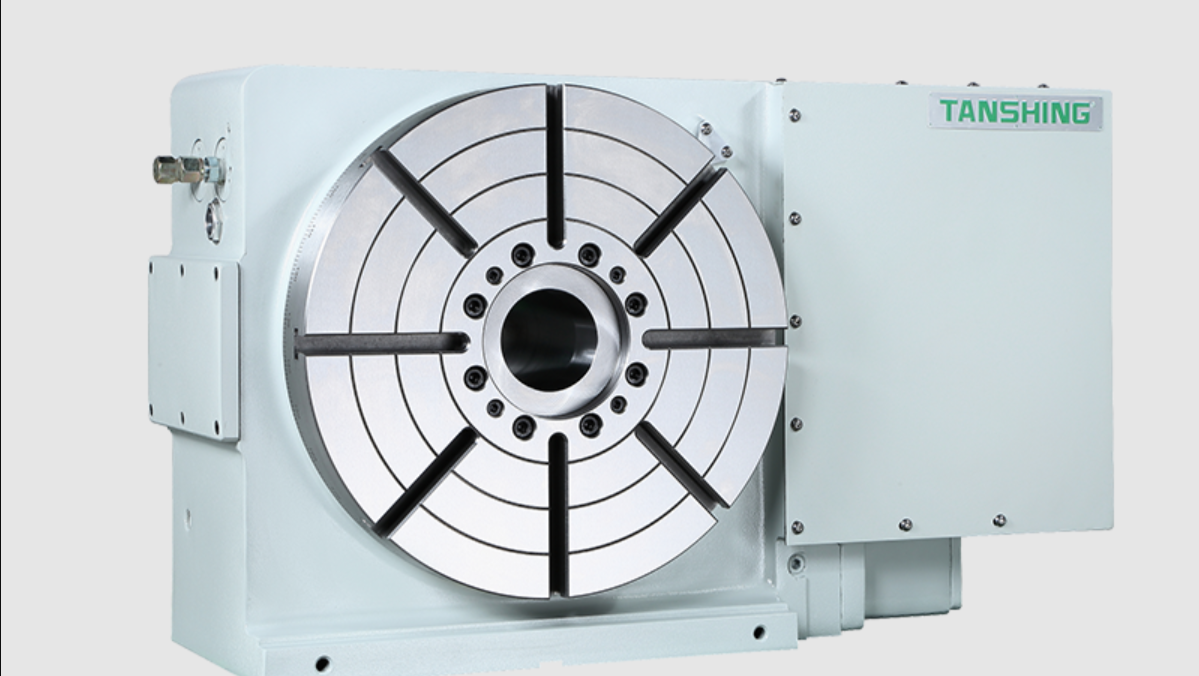

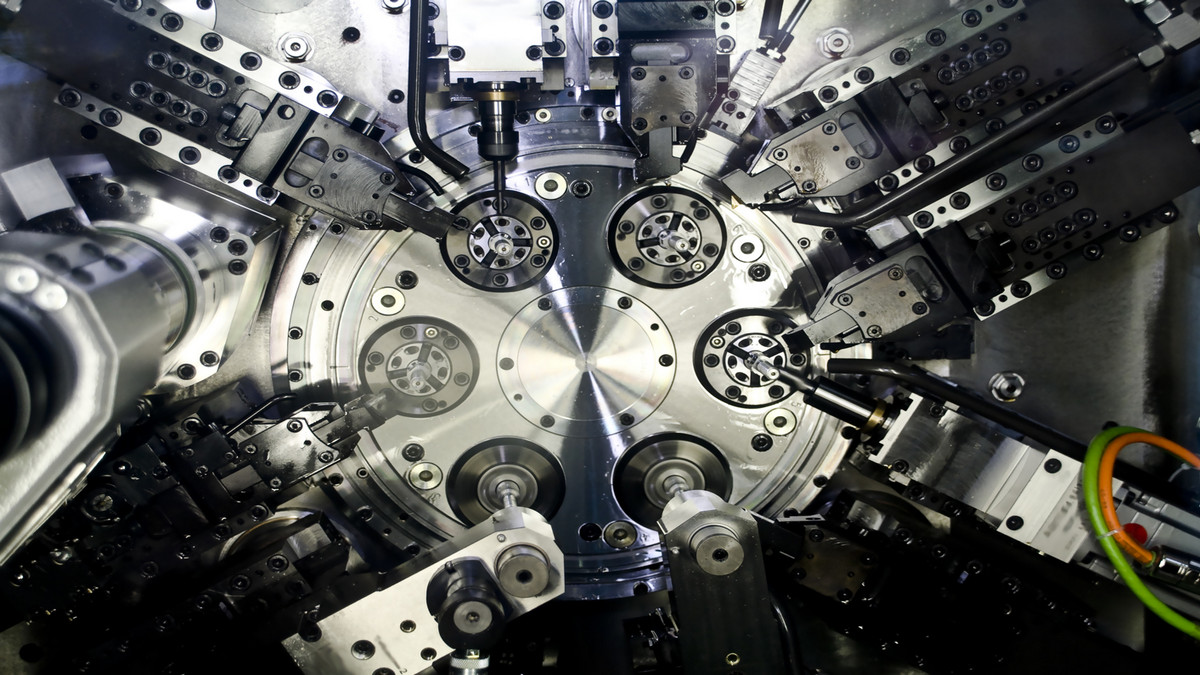

With increasing industrial automation worldwide, CNC rotary tables equipped with 4- and 5-axis capabilities have seen substantial adoption—particularly in applications requiring high precision and heavy load handling. These “smart turntables” enhance tool efficiency, machining accuracy, and production rhythm. According to Verified Market Reports, the global CNC rotary table market was valued at US $1.5 billion in 2024, projected to reach US $2.8 billion by 2033 at a 7.5% CAGR.

2025-08-04 15:48:35

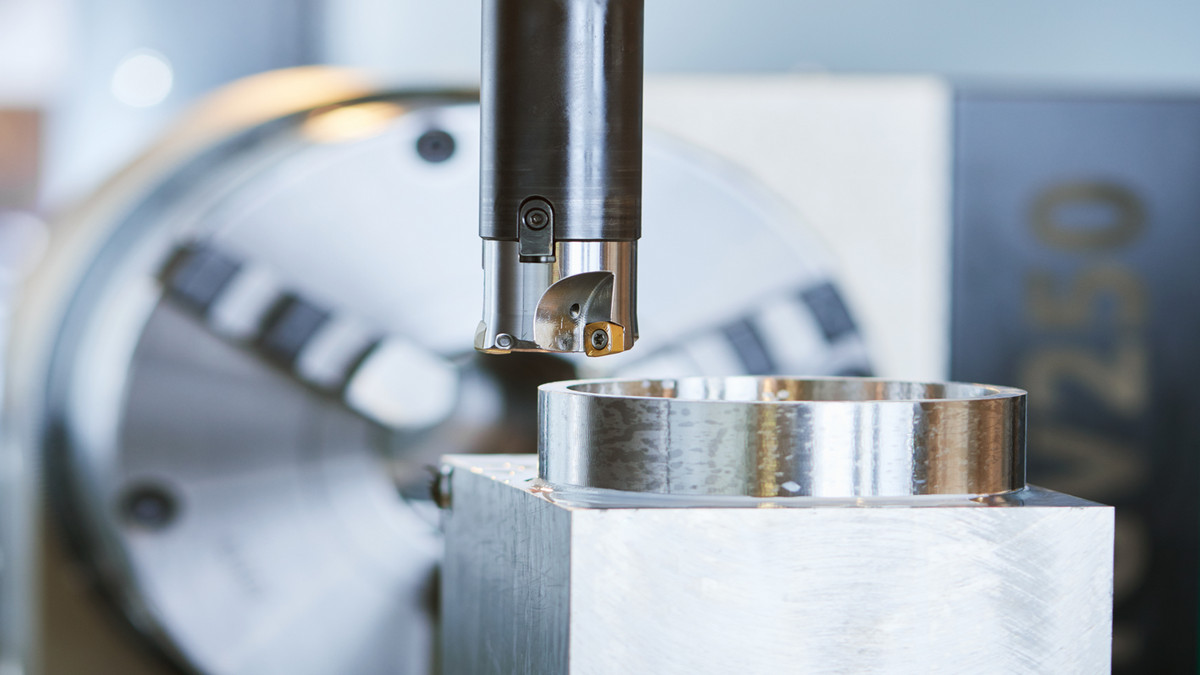

In the world of precision machining, cutting tools play a vital role. They directly determine cutting efficiency, machining accuracy, and the final product's surface quality. Even with the most advanced CNC machine tools, without the right cutting tools, their full potential can't be realized. Therefore, mastering these advanced techniques will help you achieve outstanding results in complex machining tasks while optimizing production costs.

2025-08-04 15:43:57

The Tech Industry Is Evolving Toward High Precision, High Speed, and Automation. As high-tech manufacturing advances, especially in sectors like semiconductors, optics, medical parts, and new energy components, the need for high-precision machining and automation continues to grow. These industries demand exceptional dimensional accuracy and machining stability to ensure product reliability and system performance. Modern society's growing reliance on technology fuels increasing demand for everything from consumer electronics to industrial-grade systems. This drives manufacturers to adopt faster, more efficient, and smarter solutions—requiring machining centers that can meet short lead times, flexible production volumes, and tight machining tolerances. Traditional models often struggle under the pressure of today’s precision-driven production requirements.

2025-07-25 17:07:36

Sustainable CNC machining increasingly relies on effective coolant management to reduce environmental impact, cut costs, and improve machining performance. Coolants are essential for lubrication, heat control, and chip removal, but improper handling leads to waste and higher expenses. Proper management practices—such as regular monitoring, filtration, recycling, automation, and using eco-friendly coolants—help extend coolant life, maintain machine health, and ensure consistent product quality. Although initial investment may be a barrier, the long-term benefits include cost savings, reduced waste, and enhanced operational efficiency. Future advancements in IoT and AI are expected to further optimize coolant systems, reinforcing sustainability in CNC machining.

2025-07-18 14:33:47

When it comes to the design and manufacturing of advanced equipment used in various manufacturing industries, the importance of CNC lathes and machining centers cannot be overstated. These machines are pivotal in producing high-precision parts for industries ranging from automotive to aerospace, where accuracy, repeatability, and reliability are paramount. In modern manufacturing, plastic injection machines play a critical role in producing high-volume, complex shapes that are fundamental in consumer electronics, automotive, and home appliances. Selecting the right equipment is crucial for success in any industry. Victor Taichung Machinery Works Co., Ltd., established in 1954, has evolved from a traditional lathe manufacturer into a global powerhouse in the machine tool industry. The company specializes in the design and manufacturing of CNC Lathes and Machining Centers, and it uses its own Machining Centers to manufacture its own line of Plastic Injection Machines.

2024-08-16 09:23:52

SISTER MACHINE TECHNOLOGY CO., LTD., founded in October 2006 in Taiwan, has swiftly become a leader in the design and manufacturing of advanced, high speed machining centers. SISTER specializes in double column high-speed machine centers, double column high-speed graphite machine centers, double column (gantry type) high-speed machine centers, and vertical machine centers. Each of these products embodies the company's commitment to high-speed cutting, high quality, express service, and a customer-first approach. SISTER MACHINE TECHNOLOGY’s high-speed cutting solutions cater to a broad spectrum of industrial applications, from automotive and aerospace manufacturing to intricate mold making and part production.

2024-08-16 09:04:53

Top-One Machinery, a leader in the machine tool industry, stands at the forefront of technological innovation with its high-quality, precision-engineered CNC machinery and grinding equipment. Established in 1995, Top-One has expanded its global footprint across North America, Europe, and Asia, demonstrating an unwavering commitment to excellence in machine tool manufacturing. Top-One's diverse and technologically advanced product line includes the CNC Vertical Alloy Wheel Diamond Lathe, CNC Bed Mill, Vertical Knee Milling Machine, CNC ID/OD Grinding Machine, and robust Column Machines. Each machine is designed with precision engineering to meet the high demands of today's industries.

2024-08-15 11:46:50

The CNC machining industry has seen amazing developments and innovations since the incorporation of computer programming into machining operations. CNC machining is a highly competitive industry, and among the multitude of companies striving to excel in this field, Chevalier Machinery Inc. has grown to be a leading manufacturer of CNC high-precision surface and form grinders, machining centers, turret milling machines, and multi-function lathes.

2024-05-08 15:52:26

CNC lathes have revolutionized precision engineering and manufacturing, offering unparalleled accuracy, efficiency, and versatility. Specializing in a wide array of CNC lathe types, including Swiss-Type, Slant-Bed, Gang-Type, Turret Type, and more, Greenway's parent company, Jarng Yeong Enterprise Co., Ltd, has been at the forefront of the industry since its inception in 1978. Greenway offers significant advantages and innovations that make it the optimal choice as a CNC lathe manufacturer.

2024-05-08 15:20:46

In today's rapidly evolving manufacturing industry, CNC machines have emerged as vital tools driving productivity, precision, and cost-effectiveness. Among the notable players in the field, FOCUS CNC CO., LTD stands out as a professional machine tool manufacturer specializing in the development and construction of CNC slant bed lathes. With a comprehensive product lineup, global reach, and a commitment to quality, FOCUS CNC has established itself as a leading CNC lathing OEM supplier in Taiwan.

2023-08-03 11:36:03

In the world of precision machining, Yung Cheng Shun has emerged as a trusted provider of CNC machining services. Established in 1987, the company has continually evolved to meet the demands of various industries, including medical, electronics, optics, automotive, and bicycle manufacturing. With a strong emphasis on quality control and advanced machining technologies, Yung Cheng Shun has become synonymous with precision, efficiency, and cost-effectiveness.

2023-06-29 13:56:04

NC is the most important revolution since the first industrial revolution in the manufacturing industry. Since its successful development in 1950, NC technology has been undergoing important developments in hardware and software.

2023-06-01 14:23:33

The first benefit offered by all forms of CNC machine tools is improved automation Because of the operator intervention related to producing workpieces can be reduced or eliminated.

2023-05-10 14:56:40

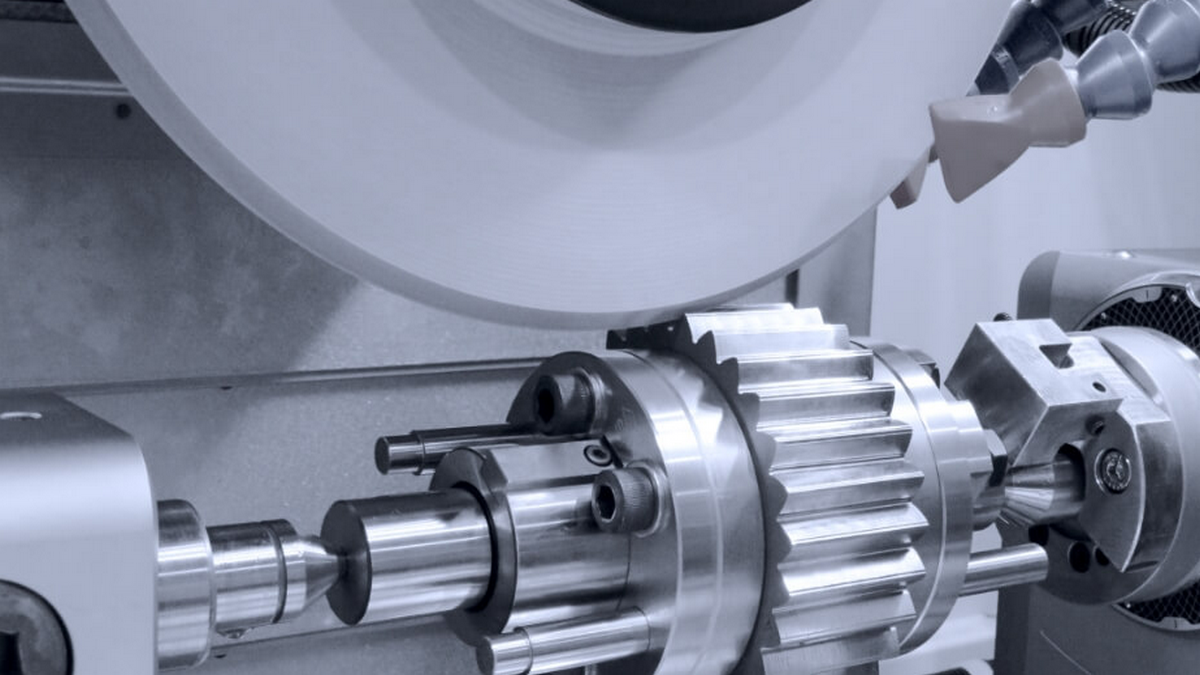

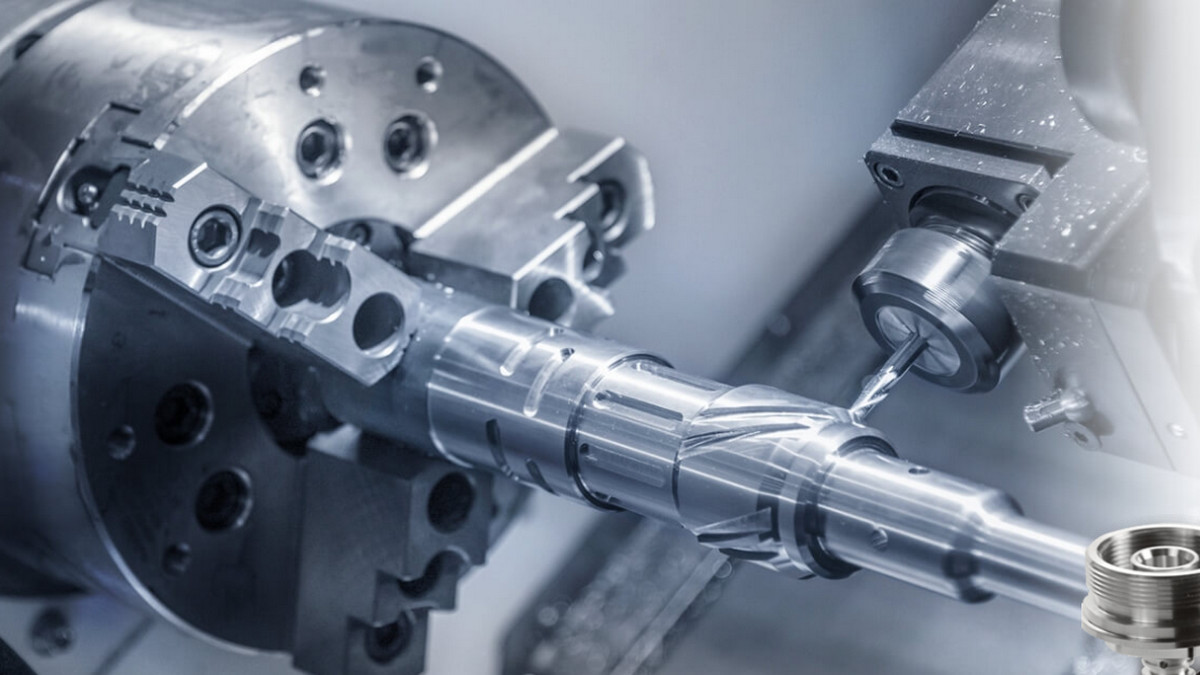

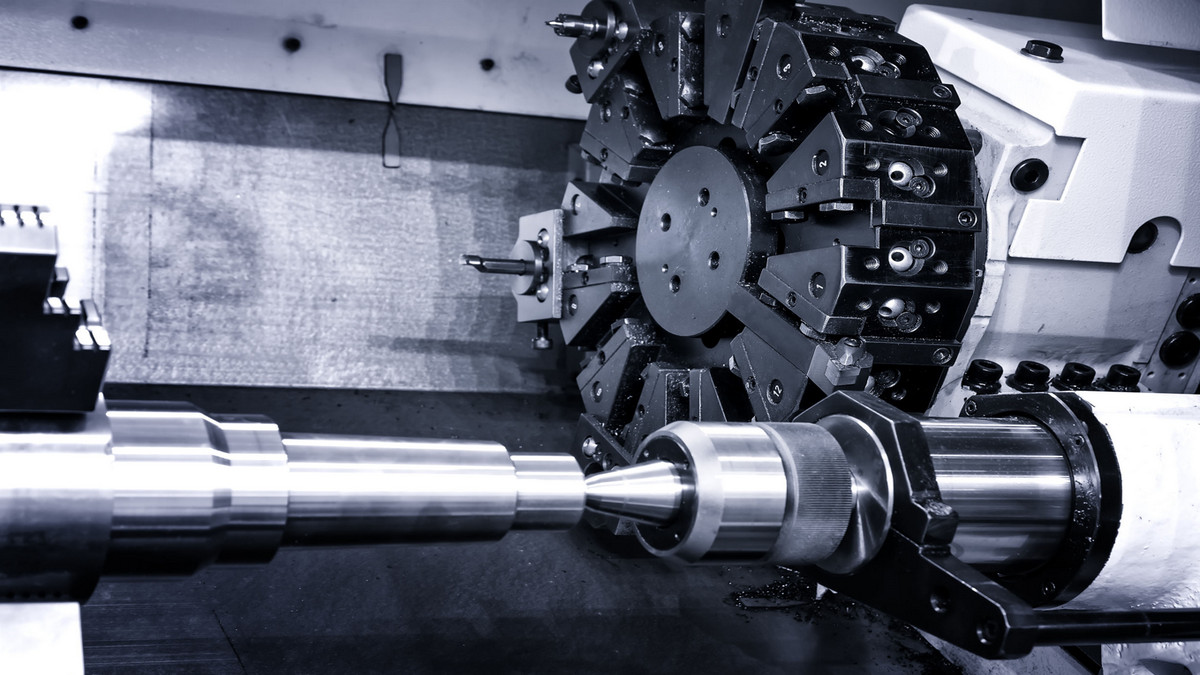

Lathes are machine tools that use turning tools to turn rotating workpieces. On the lathe, drills, reamers, reamers, taps, die and knurling tools can also be used for corresponding processing. Lathes are mainly used for processing shafts, disks, sleeves and other workpieces with rotating surfaces. They are the most widely used machine tools in machinery manufacturing and repair plants.

2023-05-10 14:51:27

A CNC machining center is a kind of CNC machining machine which has had many other functions added. Combining milling, boring, drilling, tapping, and threading functions into one machine, enables a machining center to perform multiple processes.

2023-03-28 13:43:27

Milling machines have better chip evacuation because of the nature of their configuration because gravity keeps the chips from falling. This helps improve the surface finish and prolongs the life of the tool.

2022-12-13 09:23:48

The five-axis controller is the core of the five-axis processing machine, which is used to control the trajectory of the five-axis simultaneous motion and the compensation of the motion.

2022-08-11 14:52:03

Agree