- Showing results for

- Rubber & Plastic Machinery

In today's era where digital education and maker learning are prevalent, the design of teaching tools is no longer limited to static displays but is moving toward interactivity, modularity, and creative expansion. Flexible magnetic materials—especially flexible magnets that can be cut, printed, and adhered—are gradually becoming indispensable media in the new generation of educational settings. These materials can be flexibly applied to puzzle teaching aids, display boards, and modular signage systems. Moreover, due to their ease of processing and cost-effectiveness, they widely support hands-on practice and creative activities in STEAM education (Science, Technology, Engineering, Arts, and Mathematics).

2025-08-08 14:43:37

As sustainability mandates tighten globally, plastic bag manufacturers face pressure to adopt recyclable and compostable materials. Parkins’ servo-driven bag machines enable automated, high-speed bag production using NuPlastiQ® and other biopolymers—while maintaining quality and throughput.

2025-08-08 11:32:09

Sealing machines are essential in the production of recyclable plastic bags, supporting sustainability through precision, efficiency, and compatibility with eco-friendly materials. These machines offer advanced temperature and pressure controls, which are crucial for sealing delicate bio-resins like NuPlastiQ®. Their versatility allows for the processing of various biodegradable and recyclable plastics, minimizing waste and ensuring high-quality output. Technological advancements such as automation and smart controls improve production speed and reduce energy use. By enabling the manufacture of recyclable bags, sealing machines help businesses meet environmental regulations, reduce their carbon footprint, and satisfy growing consumer demand for sustainable packaging solutions.

2025-08-07 10:52:09

Yi Tzung Precision Machinery Corp., formerly Jin Ho Sheng Iron Factory established in early 1946, upholds a legacy of advanced management philosophy and was later officially renamed Yi Tzung Precision Machinery Corp. With a long-standing history and a strong corporate reputation in the professional manufacturing of rubber and plastic machinery, Yi Tzung focuses on delivering high-end equipment and integrated solutions for the rubber and plastic processing industries. Backed by decades of industry experience and solid R&D capabilities, the company serves a diverse global clientele, driving manufacturing upgrades and industrial transformation.

2025-08-04 12:25:39

Blow molding is a specialized forming technology used to produce hollow plastic products. Its applications span across food packaging, daily chemical products, medical containers, automotive parts, and more. According to different molding methods, blow molding machines can be broadly categorized into extrusion blow molding, injection blow molding, stretch blow molding, and the rapidly growing automated all-electric blow molding technology in recent years. These technologies each offer advantages in material usage, product size, molding precision, and production line efficiency, allowing companies to choose the most suitable machine type based on product requirements and budget.

2025-08-01 14:43:19

Steady Global Market Growth As of 2024, the global plastic blow molding machine market is valued at approximately USD 3.18 billion, and it is projected to reach around USD 4.05 billion by 2030, with a compound annual growth rate (CAGR) of about 4.2%. Other reports estimate the market will grow from around USD 3 billion in 2025 to USD 8 billion by 2032, with a CAGR between 3.9% and 4.1%. Asia-Pacific as the Leading Region The Asia-Pacific region accounts for approximately 39–40% of the global market share, already reaching 38.2% in 2023. China and Taiwan are the primary growth drivers. Taiwan’s blow molding machine exports account for 9% of its plastic and rubber machinery exports, showing double-digit growth.

2025-08-01 14:08:53

Founded in 1989, PARKER PLASTIC MACHINERY CO., LTD. upholds the business philosophy of “Innovative Technology, Quality First, Customer Priority,” focusing on the research, development, and manufacturing of hollow blow molding equipment. Headquartered in Wufeng, Taichung, Taiwan, PARKER has become a significant force in the domestic and international blow molding machinery sector through continuous technological investment and rich industry experience. The company has received multiple ISO 9001 and CE certifications and was honored with the Taiwan Excellence Award in 2006, demonstrating its outstanding product quality and technical strength.

2025-08-01 12:24:12

Rubber processing is one of the most critical stages in modern manufacturing. From vehicle tires to industrial equipment seals and various consumer goods, rubber materials are everywhere. As the demand for high-quality and efficient products rises, rubber processing technologies continue to evolve. This article explores the basic knowledge of rubber processing, key technologies, and future trends.

2025-07-30 15:31:15

Aceretech is a professional plastic recycling machine manufacturer headquartered in Zhangjiagang, Jiangsu Province, China. Recognized as a national high-tech enterprise, the company specializes in the R&D and production of key equipment for shredding, washing, and pelletizing. With a focus on automated plastic recycling systems, Aceretech provides customized recycling solutions to clients across industries. The company has built an international R&D team with experts from Europe, Taiwan, and Mainland China, empowering it to develop core plastic recycling technology and deliver process-integrated machinery. Its equipment serves a broad spectrum of materials including agricultural films, appliance casings, packaging plastics, and engineering plastics.

2025-07-29 16:54:45

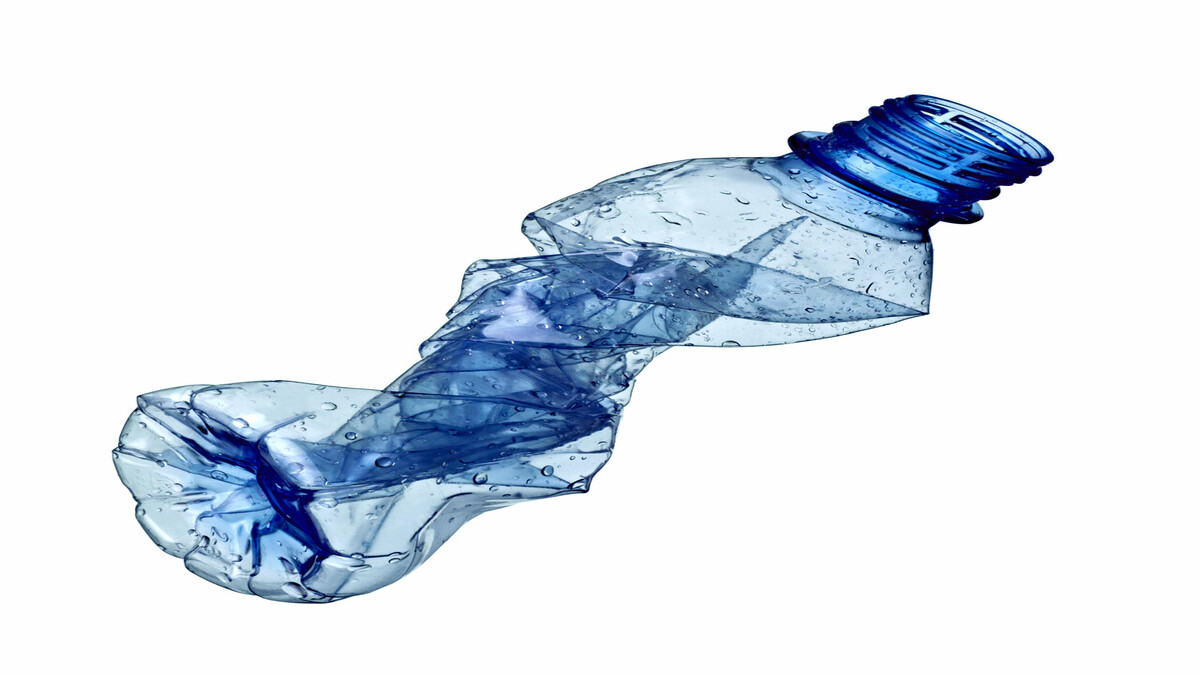

As global environmental awareness continues to grow, the plastic recycling industry is presented with new development opportunities. However, the sector still faces multiple challenges, including improving recycling rates, efficiently sorting various types of plastics, and reducing operational costs.Plastic recycling involves sorting, cleaning, and processing waste plastics into reusable materials, helping reduce pollution and promote resource reuse.

2025-07-29 08:37:52

As global concerns over environmental protection and food safety continue to grow, plastic processing and packaging equipment are undergoing a transformative shift. Taiwanese machinery manufacturers are leveraging automation, biodegradable material processing capabilities, and modular design to secure strong competitive advantages—especially in the production of everyday consumables like straws, strapping bands, shrink film, and cotton swabs

2025-07-25 14:13:20

This article provides a detailed comparison of hot and cold cutting methods used in plastic bag manufacturing, emphasizing how the choice impacts production efficiency, edge sealing, and material compatibility. Hot cutting uses heated blades to cut and seal simultaneously, making it ideal for leak-proof and high-speed production, while cold cutting offers precise, sharp cuts without heat damage, suitable for a variety of bag types. The selection depends on factors such as material type, production requirements, and environmental considerations. Understanding the strengths and limitations of each method helps manufacturers optimize their processes and meet evolving industry demands.

2025-07-04 10:31:09

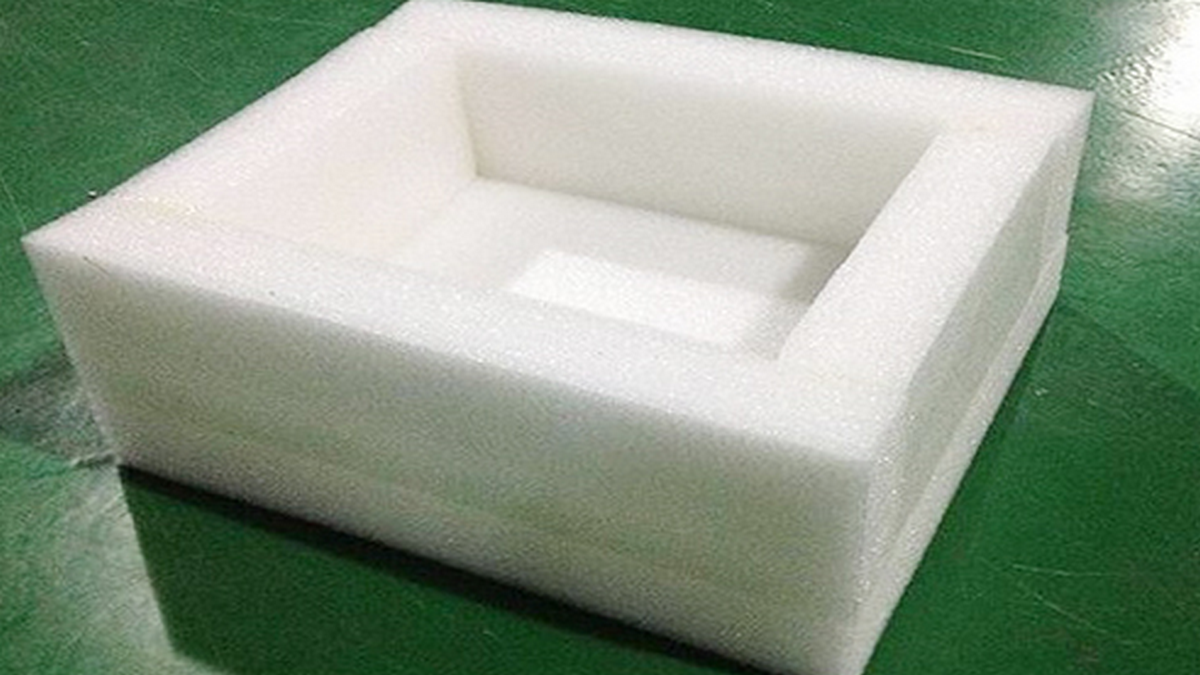

This article examines the recycling of Expanded Polyethylene (EPE) Pearl Cotton—a lightweight, shock-absorbing, and moisture-resistant packaging material. While EPE offers many benefits, its bulky form and high transportation costs make recycling difficult. However, advancements in recycling technologies and increasing environmental awareness are driving the development of more effective solutions. The report explores current challenges, emerging recycling methods, and the future potential of EPE recycling.

2025-06-18 10:33:05

In an era defined by environmental consciousness and sustainable practices, the role of plastic recycling machinery has taken center stage across various industries. Since its establishment in 1988, Matila has risen as a leader in the realm of plastic recycling and blown film machinery manufacturing. Matila stands as one of the most experienced and respected manufacturers, with extensive expertise in designing and producing Blown Film Machines, Plastic Waste Recycling Machines, Twin Screw Co-Rotary Extrusion Machines, Bags Making Machines, Plastic Printing Machines, and much more.

2023-12-21 10:18:17

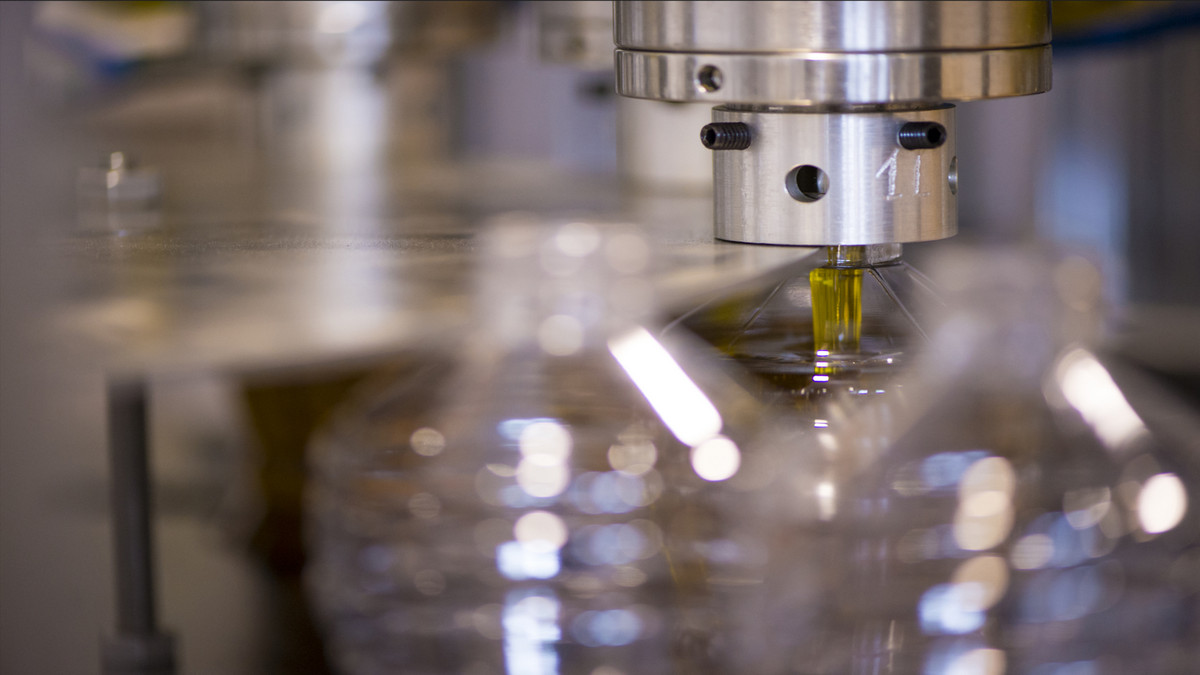

Plastic granulation technology plays a pivotal role in the manufacturing of plastic products and the recycling of resources. It is employed to produce a diverse range of plastic products or raw materials, offering both environmental and economic advantages.

2023-12-21 09:21:26

When purchasing plastic recycling machinery, careful selection of equipment is important to ensure the efficiency, effectiveness, and sustainability of your recycling operations. ACERETECH is a creative company that was founded in 2015. ACERETECH focuses on providing machinery that maximizes the recovery and reuse of materials during the recycling process. Efficient material recovery systems contribute to reducing waste and conserving resources.

2023-12-07 11:42:29

In the pursuit of more sustainable and environmentally friendly alternatives, the use of PHA and PLA marine degradable straws has garnered significant attention. With the increasing demand for these eco-conscious solutions, manufacturers like Jumbo Steel Machinery are taking the lead in offering state-of-the-art PHA and PLA marine degradable straw making machines. This article explores the unique qualities of these machines, considerations for their manufacturing, the features that enhance quality and efficiency, and the growing popularity of PHA and PLA degradable straws.

2023-11-07 15:02:04

In the today’s world of plastics extrusion, one company has consistently stood out as a professional and reliable manufacturer of high-quality plastic sheet extrusion machines: Shang Ta Chia Industrial Co., Ltd. With a rich history dating back to 1984, Shang Ta Chia has earned a trusted reputation for designing and manufacturing top-of-the-line PP, PS, PE, and PVC plastic sheet extrusion machines. Their extensive range of offerings includes PP/PC/PVC Corrugated Sheet Extrusion machines, PET Sheet Twin Screw Extrusion machines, and more.

2023-08-31 10:46:33

With the rise of global environmental protection awareness, the improvement of process efficiency and pollution reduction of plastic products have become important issues for the rubber and plastic industry. In response to the shortage of workers and the reduction of personnel contact, mechanical automation and cloud services have become the new normal in the industry.

2023-04-12 14:41:36

Plastic products can be seen everywhere in daily life, and different plastic products are made through different processing techniques. Plastics manufacturing is the process of making plastic into semi-products or products with practical value. Plastics manufacturing usually includes primary processing and secondary processing of plastics.

2023-03-09 13:49:34

Agree

.jpg)