This article examines the recycling of Expanded Polyethylene (EPE) Pearl Cotton—a lightweight, shock-absorbing, and moisture-resistant packaging material. While EPE offers many benefits, its bulky form and high transportation costs make recycling difficult. However, advancements in recycling technologies and increasing environmental awareness are driving the development of more effective solutions. The report explores current challenges, emerging recycling methods, and the future potential of EPE recycling.

Expanded Polyethylene (EPE) Pearl Cotton is a widely used packaging material valued for its lightweight, shock-absorbing, and moisture-resistant qualities. However, despite its advantages, recycling EPE presents considerable challenges due to its bulky nature and the high costs associated with collection and transportation. With the advancement of recycling technologies and a growing global focus on sustainability, more efficient recycling solutions are emerging. This article provides an in-depth look at the current landscape of EPE Pearl Cotton recycling, highlighting its challenges, viable solutions, and future outlook.

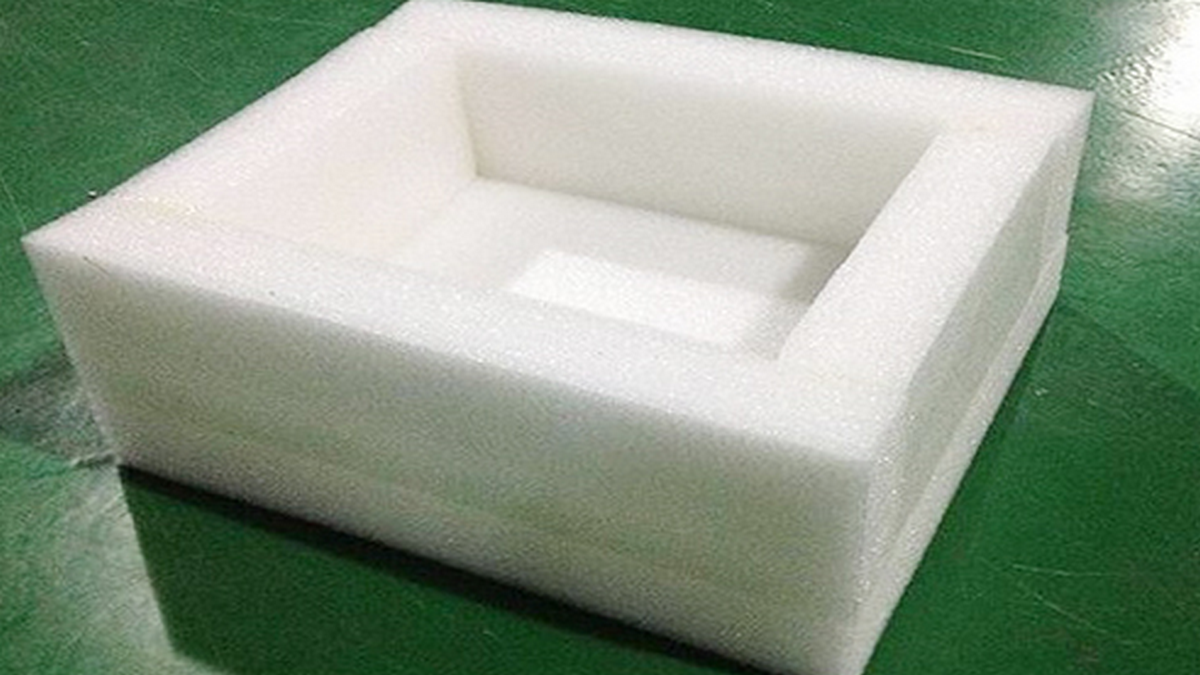

What is EPE Pearl Cotton?

EPE Pearl Cotton is a non-crosslinked, closed-cell material made through physical foaming of low-density polyethylene (LDPE), resulting in numerous independent air bubbles. Compared to conventional Styrofoam, it offers improved durability, resilience, and reusability. Key benefits include water and moisture resistance, shock absorption, sound insulation, thermal preservation, excellent plasticity, strong toughness, recyclability, and high impact resistance.

Characteristics and Recycling Challenges

As a thermoplastic material, EPE Pearl Cotton has excellent remelting properties, making it inherently recyclable. Nonetheless, large-scale recycling efforts are hindered by its lightweight and voluminous structure, which make transportation and collection logistically and financially burdensome. Moreover, limited availability of specialized recycling equipment and infrastructure further reduces actual recycling rates in many regions.

.png)

Referral Link

Recycling Methods for EPE Pearl Cotton

Shredding and Extrusion: One of the primary methods for EPE recycling is shredding the foam into smaller pieces, followed by extrusion to create new products. This method employs shredders specifically designed for polyethylene foam. These machines provide uniform discharge, high throughput, and strong processing capacity, making them ideal for industrial-scale recycling.

Compacting and Pelletizing: ACERETECH Machinery's ACS-H series compacting and pelletizing system is another effective solution. EPE waste is conveyed into a compactor, where high-speed rotary blades cut and heat the material via friction. The melted material is then processed with a double-zone vacuum degassing system to eliminate impurities, resulting in uniform plastic pellets ready for reuse in manufacturing.

Foam Densification: Foam densification involves compressing EPE into dense blocks, significantly reducing its volume. Machines like the GREENMAX foam densifier can reduce EPE volume by up to 50 times, improving storage and transport efficiency. This method offers economic advantages by allowing the compacted material to be sold or repurposed.

Hot-Melt Technology: Another recycling approach is hot-melt processing, in which EPE foam is melted at high temperatures to form dense, moldable material. This method achieves a high compression ratio and is efficient for processing various EPE foam waste types.

Future Outlook

The future of EPE Pearl Cotton recycling is optimistic, especially as more industries adopt circular economy practices and closed-loop systems. Continued innovation in pelletizing technologies and increased international collaboration in waste management are essential to reducing the environmental impact and enhancing resource efficiency. As sustainability awareness grows, so too will the demand for effective recovery and reuse of EPE materials.

.png)

Referral Link

Conclusion

While EPE Pearl Cotton poses recycling challenges, it also presents significant opportunities for sustainable reuse. With ongoing technological advances and a rising commitment to environmental stewardship, the industry is progressing toward more efficient and scalable recycling solutions. By harnessing cutting-edge machinery and fostering global cooperation, EPE waste can be transformed into valuable resources, supporting a more sustainable and circular future.

.png)

.png)

.png)