- Showing results for

- Smart Manufacturing

In 2025, as global manufacturing continues its rapid digital transformation, the machine tool industry is facing significant change. International buyers in aerospace, electric vehicles, and high-end electronics are increasingly prioritizing smart services and data applications over mere machining precision. Taiwan's machine tool industry is actively integrating the Internet of Things (IoT), artificial intelligence, and big data technology, expanding from traditional hardware manufacturing into the smart solutions sector. This move helps global manufacturing clients boost production efficiency and enhance equipment maintenance management. This article will delve into how Taiwan's machine tool industry is becoming an indispensable smart partner for global manufacturing, delivering sustained value.

2025-08-27 14:56:00

The global manufacturing industry is experiencing a profound transformation towards intelligence and precision. Market demands for higher precision, greater efficiency, and flexible production are increasingly urgent. Facing the challenges of high-mix, low-volume (HMLV) flexible manufacturing, enterprises critically need to balance high-precision machining with rapid responsiveness. TOP-ONE Machinery Co., Ltd. , leveraging its deep expertise in precision CNC machine tool R&D and exceptional customization capabilities, is actively engaging in this transformation. We are committed to empowering global clients to overcome transformation challenges and enhance manufacturing competitiveness through innovative solutions.

2025-08-21 12:15:18

The global textile industry landscape is undergoing a rapid transformation. Southeast Asia, with its unique cost advantages, policy support, and industrial upgrades, is emerging as a new supply chain hub. As international brands actively diversify their production bases, key countries like Vietnam and Indonesia are becoming hot spots for foreign and technological investment. This article will delve into the driving forces behind the rise of the Southeast Asian textile industry, analyze the current production status and investment trends of major countries, and examine the challenges and future development directions of the industry, helping businesses seize new opportunities in the restructuring of the global supply chain.

2025-08-21 11:37:25

Amid the global wave of intelligent manufacturing and low-carbon transformation, Yen Shen Electric Industrial Co., Ltd. centers on motor design, drive control, and energy efficiency integration to steadily promote industrial upgrading. Upholding the philosophy of "integration, simplification, and innovation," Yen Shen focuses on synergistic design of motors and controllers, assisting industries to implement high-efficiency, low-energy-consumption intelligent power solutions, offering tangible support for energy-saving manufacturing.

2025-08-20 11:26:33

Historically, the global textile industry relied on mass production and economies of scale for low-cost manufacturing. However, as consumer demands become increasingly diverse and dynamic, small-batch, high-mix production and fast delivery have become the market mainstream. Taiwan, with its complete and advanced textile supply chain and high-end functional fabric technology, has long demonstrated competitiveness on the international stage. Facing global supply chain restructuring and the fast fashion trend, Taiwan's textile industry is actively pursuing a digital and localized transformation. The goal is to build a flexible, responsive agile supply chain, making manufacturing a sustained competitive advantage.

2025-08-14 14:58:50

As the demand for medical and health care continues to rise, YOHO Medical Enterprise Co., Ltd. (YOHO Medical) leverages its years of professional medical consumables manufacturing experience. It extends the strict standards of professional healthcare to various aspects of life, carefully creating five product lines covering professional medical, mother and baby care, medical beauty care, home and pet supplies, and industrial equipment. YOHO Medical adheres to strict manufacturing standards and excellent quality, continuously meeting diverse market demands and solidifying its trustworthy brand image.

2025-08-13 10:38:10

The global manufacturing industry is facing an unprecedented green revolution, and the machine tool industry is at its epicenter. With the phased implementation of the EU's Carbon Border Adjustment Mechanism (CBAM) and strict Eco-design directives, carbon emission thresholds for mechanical equipment have become mandatory. This isn't just a rule for the European market; Asia and the U.S. are also tightening their energy-saving requirements, forcing global machine tool manufacturers to completely restructure their products and processes. Companies that fail to comply with the new green standards may be excluded from international supply chains. A new green competition, which will determine corporate survival and future market position, has begun.

2025-08-12 12:24:03

Taiwan’s machine tool industry holds a crucial position in the global precision manufacturing supply chain. However, a silent "talent crunch" and "knowledge succession crisis" are now threatening its future. With the acceleration of smart manufacturing, AI, and automation, the industry's demand for high-end, cross-disciplinary talent—skilled in electrical control, software integration, and AI applications—has surged. Yet, the market supply is severely insufficient, hindering the industry's digital transformation and upgrade. Industry observers warn that if this gap continues to widen, Taiwan's international competitiveness in the machine tool sector could face significant challenges within the next five to ten years.

2025-08-08 09:49:59

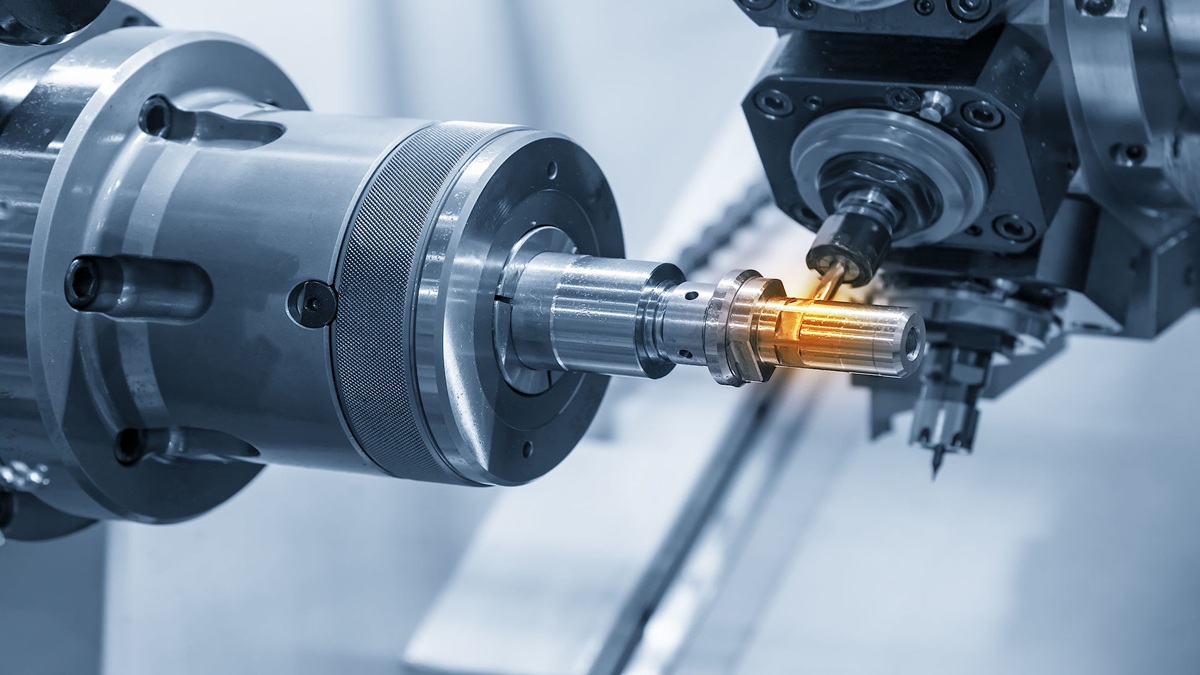

With the rapid development of industries such as aerospace, medical equipment, new energy, and high-end electronics, there's an increasing demand for materials with properties like lightweight, high strength, high temperature resistance, and corrosion resistance. This has led to the widespread application of advanced materials such as titanium alloys, nickel-based superalloys, and carbon fiber reinforced plastics (CFRP). While these materials offer excellent performance, their processing presents severe challenges to traditional machine tools due to issues like high hardness, poor thermal conductivity, and a tendency to work-harden. However, this has also become a powerful force driving machine tool innovation and upgrades, prompting machine tool manufacturers to seek breakthroughs in precision, rigidity, thermal stability, and multi-tasking technology.

2025-08-08 08:37:41

In the context of the global manufacturing industry's ongoing transformation and upgrading, plastic injection molding has become an indispensable link in the supply chain and a key factor for brands to create product differentiation and seize market opportunities. Since its establishment in 1974, Shin Fang Plastic Industrial Co., Ltd. has leveraged over fifty years of industry experience to offer diverse plastic part solutions from product design to mass production, helping customers capture market advantages. This article delves into Shin Fang’s core values in injection manufacturing, customization capabilities, and its new approach amid smart manufacturing and sustainability trends, demonstrating its solid strength as a leading OEM/ODM plastic part manufacturer.

2025-08-07 16:25:22

As the global demand for sustainability and safety in food packaging and takeout continues to grow year by year, both brand clients and end consumers are placing greater emphasis on food-grade paper and biodegradable coatings. Since transitioning into the paper container manufacturing industry in 1991, HUANG GUAN SPECIAL PRINTERY CO., LTD. has consistently invested in R&D and equipment upgrades to stay ahead of the ever-evolving market trends.

2025-08-04 12:23:18

The manufacturing industry is currently at a critical crossroads of dramatic change. With the advent of Industry 5.0 and the wave of digital transformation, product designs are becoming increasingly complex, and material selections are trending towards high hardness and difficult-to-machine properties. This presents a true test for the machining tools responsible for the final product quality. Industries such as molds, semiconductors, optics, and aerospace no longer just demand that tasks be "done," but that they be "done precisely, efficiently, and sustainably." Traditional tools often fall short in durability, precision, and efficiency when facing high-hardness materials like tungsten carbide and ceramics, as well as complex, confined geometric spaces. The market not only needs tougher tools but also solutions that can adapt to smart manufacturing trends, improve overall yield, and reduce total costs.

2025-08-02 16:54:38

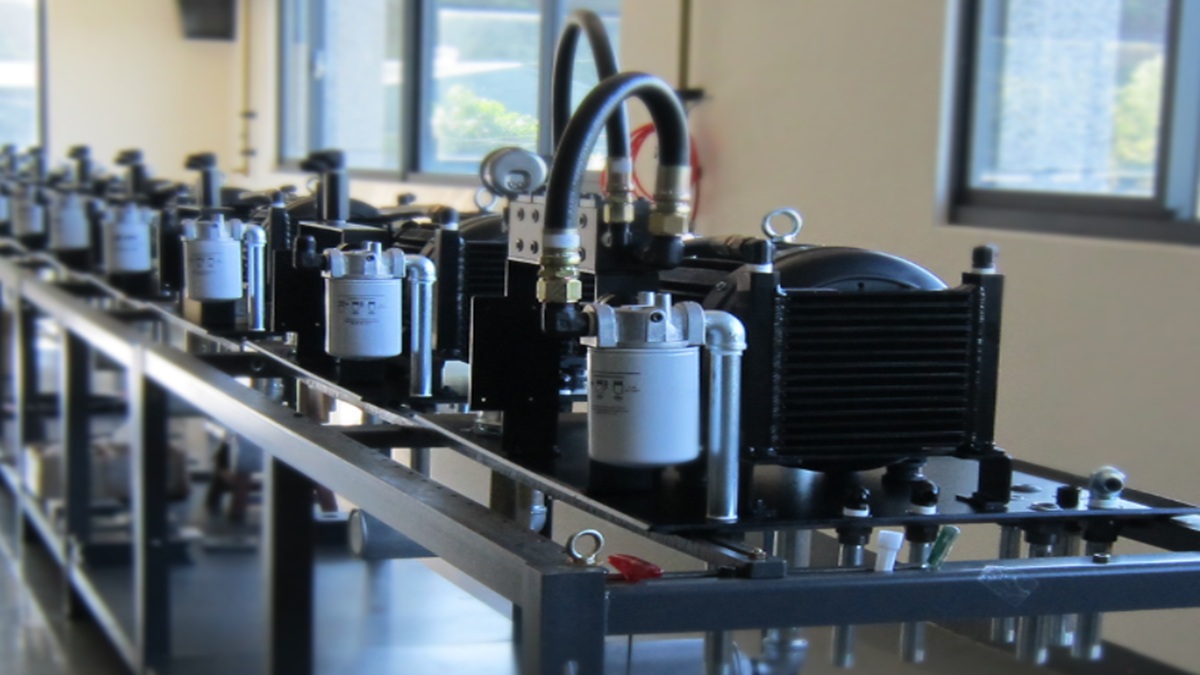

Global energy costs continue to rise alongside stricter carbon emission regulations worldwide, motivating manufacturers to pursue sustainability and energy efficiency. Traditional hydraulic systems consume high energy and incur significant operating costs, increasing enterprise burdens and hindering production line modernization. AnyPower Hydraulic Industry Co., Ltd. has independently developed a servo energy-saving hydraulic unit precisely designed to meet these market demands, providing key solutions for partners to achieve energy savings and sustainable growth.

2025-07-31 15:08:41

The global manufacturing industry is rapidly evolving, and companies need to find partners who are efficient, high-quality, and capable of integrated services to maintain competitiveness. Jinholly Co., Ltd., a Taiwan-based company deeply rooted in precision metal processing, is providing clear solutions for this industrial transformation through its unique "one-stop" service model.

2025-07-30 13:49:41

As global attention on sustainable development and the green economy rapidly increases, eco-friendly new materials have become the mainstream direction for industrial innovation. Successful Mat has long specialized in the research, development, and manufacturing of foam products, actively embracing the concept of a circular economy. By incorporating recycled EVA and POE materials together with bio-based fillers such as bamboo powder and rice husk powder, foam solutions are delivered that combine environmental responsibility with functionality for the sports & leisure, construction, and agricultural sectors. Through continuous innovation in low-carbon materials and smart manufacturing, Successful Mat not only aligns with global sustainability trends but also works hand in hand with its clients to build a low-carbon, circular future—enhancing both the environmental value and brand impact of its products.

2025-07-30 11:18:45

The conventional manufacturing sector stands at a crossroads necessitating a shift towards intelligent transformation. By incorporating advanced production technologies, a new era of industrial development is inaugurated.

2023-12-21 13:36:14

5G is recognized as a key enabler of Industry 4.0. With its high network speed and low power consumption, 5G facilitates the connectivity of every sensor in the upcoming unmanned factory to the cloud. This connectivity allows for the extraction of data for analysis, ultimately fueling advancements in artificial intelligence.

2023-11-24 15:29:06

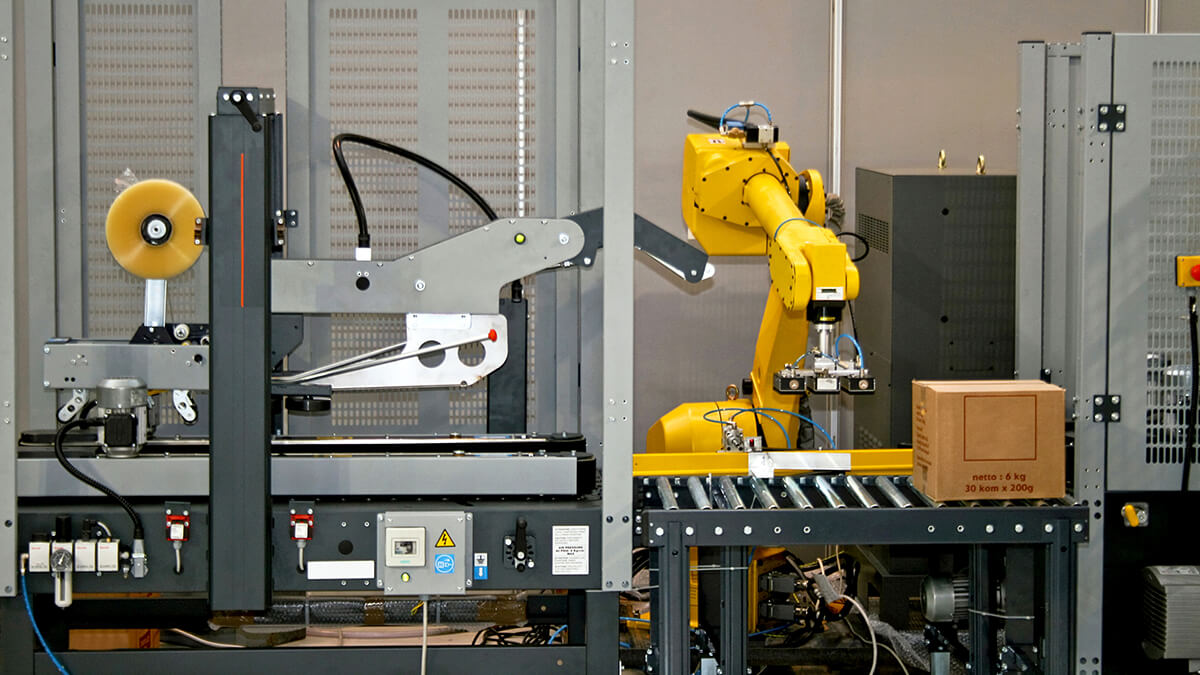

The integration of collaborative robots into production has become a pivotal element in the manufacturing chain, enhancing overall production efficiency. These compact collaborative industrial robots are designed to operate in confined spaces, addressing challenges posed by limited working spaces.

2023-11-24 15:13:23

Nowadays, the traditional industry combines the technology of the Internet of Things, towards the innovation of Industry 4.0 and the development of intelligent manufacturing.

2023-08-03 10:21:44

"Efficiency" is the most important key in the pursuit of success in the manufacturing process and the entire industry.

2023-07-07 13:39:07

Agree