With the rapid development of industries such as aerospace, medical equipment, new energy, and high-end electronics, there's an increasing demand for materials with properties like lightweight, high strength, high temperature resistance, and corrosion resistance. This has led to the widespread application of advanced materials such as titanium alloys, nickel-based superalloys, and carbon fiber reinforced plastics (CFRP). While these materials offer excellent performance, their processing presents severe challenges to traditional machine tools due to issues like high hardness, poor thermal conductivity, and a tendency to work-harden. However, this has also become a powerful force driving machine tool innovation and upgrades, prompting machine tool manufacturers to seek breakthroughs in precision, rigidity, thermal stability, and multi-tasking technology.

Challenges in Processing High-Strength Metal Materials and Machine Tool Solutions

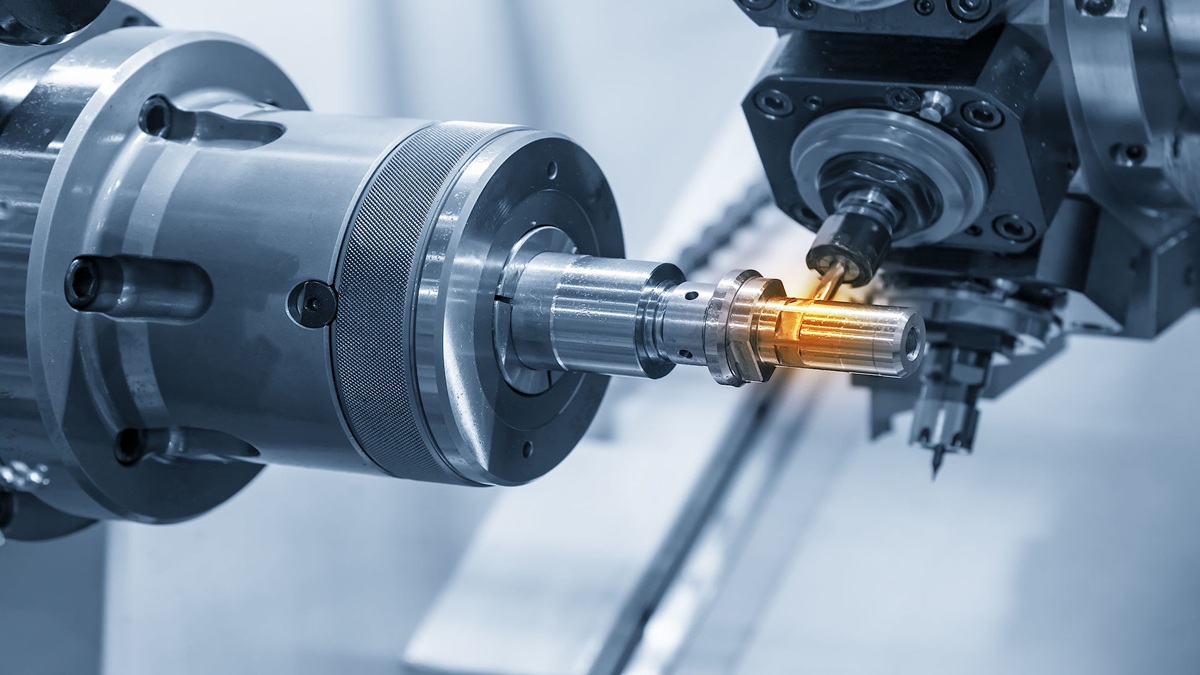

High-strength metal materials such as titanium alloys and nickel-based superalloys are widely used in critical components like aero-engine blades and medical implants due to their excellent strength-to-weight ratio and high-temperature resistance. However, their low thermal conductivity and high chemical reactivity lead to difficulty dissipating cutting heat, which can accelerate tool wear and degrade the quality of the machined surface.

To address these challenges, machine tool manufacturers are actively developing:

- High-rigidity and high-damping machine structures:

Adopting one-piece castings, mineral castings, or composite beds to enhance the overall rigidity and vibration resistance of the machine, effectively suppressing machining vibrations and ensuring cutting stability.

- High-torque, low-speed spindles:

Designing spindles with high torque output specifically for difficult-to-cut materials. This, combined with low-speed cutting, reduces the generation of cutting heat and extends tool life.

- High-efficiency cooling and lubrication systems:

Introducing high-pressure through-spindle coolant, Minimum Quantity Lubrication (MQL), or even cryogenic cooling technologies to deliver cutting fluid directly to the cutting zone, effectively removing heat and improving cutting conditions.

Special Requirements and Technological Breakthroughs for Composite Material Processing

Carbon fiber reinforced plastics (CFRP) are increasingly used in the aerospace and automotive industries for their lightweight and high-strength properties. However, the anisotropy, delamination tendency, and abrasive nature of CFRP pose unique challenges to machine tools.

The development directions for machine tools in composite processing include:

- Specialized tools and processing strategies:

Developing diamond-coated or polycrystalline diamond (PCD) tools combined with optimized cutting parameters to reduce delamination and burrs. Techniques like drill-milling and ultrasonic-assisted machining are also used to lower cutting forces and improve machining quality.

- High-precision motion control:

Due to the anisotropy of composite materials, precise control of the machining path is crucial. The use of 5-axis or even multi-axis machine tools enables continuous processing of complex curved surfaces, avoiding errors caused by multiple setups.

- Dust and waste management:

CFRP machining generates a large amount of fiber dust, which is a threat to equipment and operator health. Machine tools must be equipped with efficient dust collection systems and safety measures.

Ultra-Precision Machining and Surface Integrity Requirements

As industry demands for part performance increase, not only dimensional accuracy but also Surface Integrity has become a crucial metric for evaluating machining quality. For advanced materials, defects such as residual stress, micro-cracks, and recast layers on the machined surface can severely impact their fatigue life and corrosion resistance.

To achieve high Surface Integrity, machine tools are evolving in the following directions:

- Sub-micron precision control:

Achieving sub-micron or even nanometer-level precision in machine tool motion through high-precision optical scales, direct-drive motors, and advanced control algorithms, ensuring ultimate dimensional accuracy.

- Integration of non-traditional machining technologies:

Combining non-contact or low-stress machining methods like laser processing, Electrical Discharge Machining (EDM), Electrochemical Machining (ECM), or ultrasonic-assisted machining to reduce thermal effects and mechanical damage to the material surface.

- In-process measurement and compensation:

Integrating high-precision sensors and vision systems to measure part dimensions and surface conditions in real-time during machining, with automated adjustments to processing parameters for closed-loop control.

Integrated Application of Machine Tool Multi-Tasking Technology

Given the complexity of advanced materials processing, a single machining method is often insufficient. The use of multi-tasking machines (e.g., mill-turn and grind-mill machines) is becoming increasingly common. These machines integrate multiple processing functions onto a single machine tool, allowing for the completion of multiple operations in a single setup, which significantly improves machining efficiency and accuracy.

The advantages of multi-tasking machines are reflected in:

- Reduced processing time:

Minimizing the transfer and setup times of parts between different machines, greatly shortening the overall processing cycle.

- Improved machining accuracy:

Avoiding cumulative errors from multiple setups, ensuring the geometric and positional accuracy of parts.

- Enhanced flexible manufacturing capabilities:

A single piece of equipment can complete a variety of complex machining tasks, making it more suitable for small-batch, multi-variety production models.

- Space saving:

Compared to multiple single-function machine tools, multi-tasking machines can effectively save factory floor space.

Advanced Materials Processing Drives the Future Development of Machine Tools

The widespread use of advanced materials has not only brought unprecedented technical challenges to the machine tool industry but also provided immense opportunities for innovation. From high-rigidity structures and high-efficiency cooling systems to specialized tool development, ultra-precision machining technology, and the integration of multi-tasking machines, machine tool manufacturers are actively investing in R&D to meet ever-increasing processing demands.

It is foreseeable that the future development of machine tools will be closely intertwined with advancements in materials science, jointly pushing the manufacturing industry toward an era of higher performance and greater efficiency. For machine tool companies, mastering the key technologies for advanced materials processing will be the decisive factor in maintaining a leading position in the market.