- Showing results for

- Machine Tool

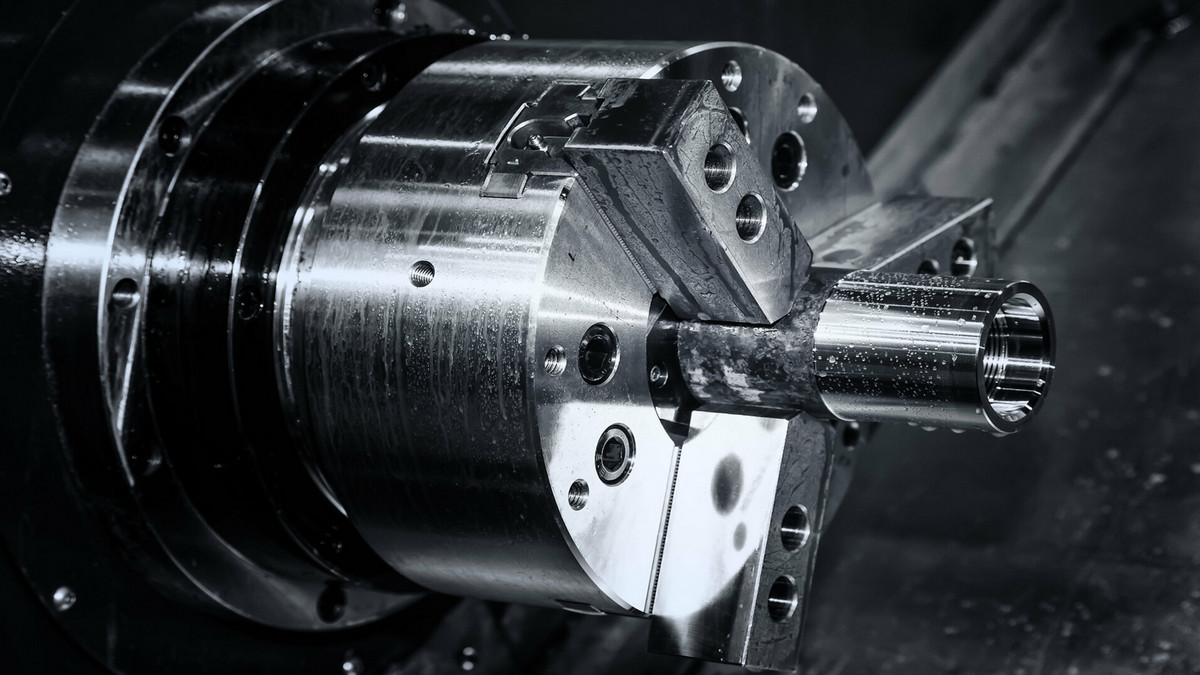

The global precision manufacturing industry is facing unprecedented challenges: completing complex, multi-angle workpieces within tight deadlines while maintaining stringent precision. In this environment, five-axis machining has become a critical key to boosting corporate competitiveness. TOP SDISK (Spintop Machinery Co., Ltd.) tackles this challenge head-on by leveraging industry-leading direct drive motors and cam technology to build high-speed, high-rigidity double-axis CNC rotary tables, injecting intelligence and innovation into the manufacturing sector.

2025-08-27 15:56:14

In 2025, as global manufacturing continues its rapid digital transformation, the machine tool industry is facing significant change. International buyers in aerospace, electric vehicles, and high-end electronics are increasingly prioritizing smart services and data applications over mere machining precision. Taiwan's machine tool industry is actively integrating the Internet of Things (IoT), artificial intelligence, and big data technology, expanding from traditional hardware manufacturing into the smart solutions sector. This move helps global manufacturing clients boost production efficiency and enhance equipment maintenance management. This article will delve into how Taiwan's machine tool industry is becoming an indispensable smart partner for global manufacturing, delivering sustained value.

2025-08-27 14:56:00

In the fast-evolving global manufacturing landscape, electric vehicles (EVs), semiconductors, and aerospace industries are emerging as key drivers of technological upgrades. These sectors share a common requirement for complex and high-precision components, which conventional machining methods alone can no longer fully address. This demand is reshaping the machine tool industry chain, from upstream components to midstream machine manufacturing and downstream applications, all showing strong trends toward integration and intelligent development.

2025-08-26 15:54:52

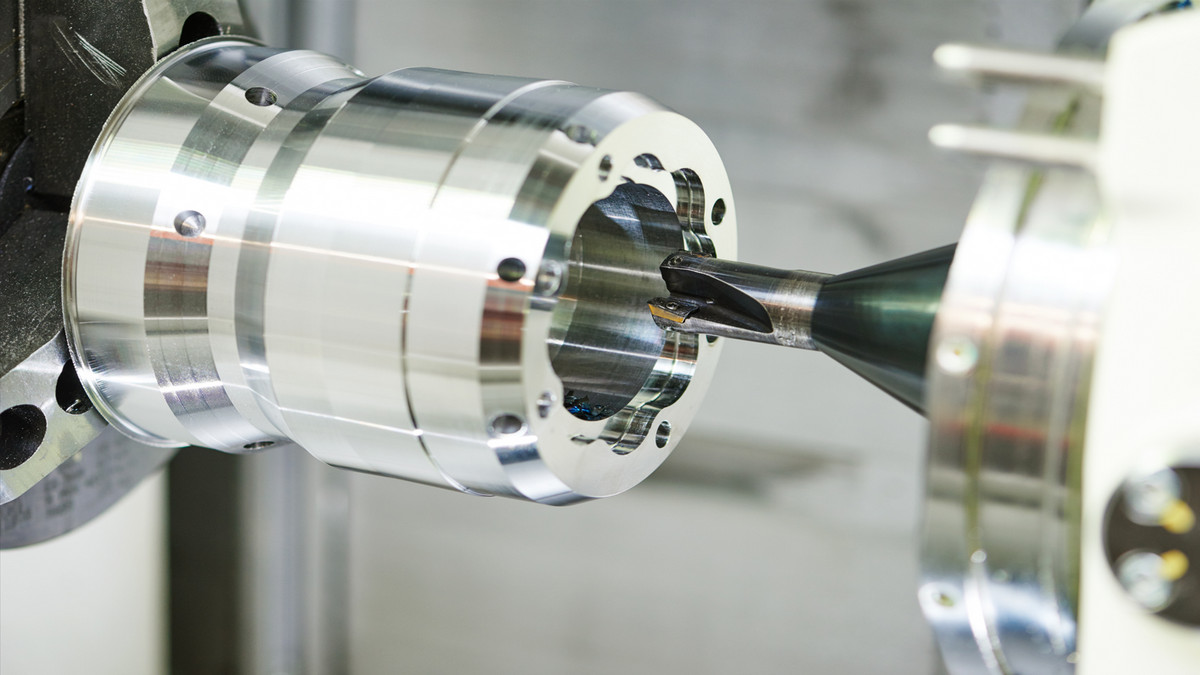

The medical industry is experiencing rapid growth, driven by an aging population, rising chronic diseases, and technological advancements. The demand for high-precision medical devices is increasing, requiring manufacturing processes that ensure safety, reliability, and performance. Machine tools play a critical role in meeting these stringent requirements, enabling the production of complex medical instruments with exceptional accuracy.

2025-08-26 15:20:47

The global manufacturing industry is experiencing a profound transformation towards intelligence and precision. Market demands for higher precision, greater efficiency, and flexible production are increasingly urgent. Facing the challenges of high-mix, low-volume (HMLV) flexible manufacturing, enterprises critically need to balance high-precision machining with rapid responsiveness. TOP-ONE Machinery Co., Ltd. , leveraging its deep expertise in precision CNC machine tool R&D and exceptional customization capabilities, is actively engaging in this transformation. We are committed to empowering global clients to overcome transformation challenges and enhance manufacturing competitiveness through innovative solutions.

2025-08-21 12:15:18

The global manufacturing industry is facing an unprecedented green revolution, and the machine tool industry is at its epicenter. With the phased implementation of the EU's Carbon Border Adjustment Mechanism (CBAM) and strict Eco-design directives, carbon emission thresholds for mechanical equipment have become mandatory. This isn't just a rule for the European market; Asia and the U.S. are also tightening their energy-saving requirements, forcing global machine tool manufacturers to completely restructure their products and processes. Companies that fail to comply with the new green standards may be excluded from international supply chains. A new green competition, which will determine corporate survival and future market position, has begun.

2025-08-12 12:24:03

In the current wave of global manufacturing transformation, digitalization and connectivity have become the core drivers propelling the machine tool industry toward smart factories. This goes beyond merely connecting traditional equipment to networks; it involves leveraging data collection, analysis, and application to achieve comprehensive optimization of production processes, enhanced efficiency, and flexible manufacturing. From single-machine intelligence to production line collaboration, digitalized and connected technologies are rapidly transforming the design, manufacturing, operation, and maintenance of machine tools.

2025-08-08 09:15:57

With the rapid development of industries such as aerospace, medical equipment, new energy, and high-end electronics, there's an increasing demand for materials with properties like lightweight, high strength, high temperature resistance, and corrosion resistance. This has led to the widespread application of advanced materials such as titanium alloys, nickel-based superalloys, and carbon fiber reinforced plastics (CFRP). While these materials offer excellent performance, their processing presents severe challenges to traditional machine tools due to issues like high hardness, poor thermal conductivity, and a tendency to work-harden. However, this has also become a powerful force driving machine tool innovation and upgrades, prompting machine tool manufacturers to seek breakthroughs in precision, rigidity, thermal stability, and multi-tasking technology.

2025-08-08 08:37:41

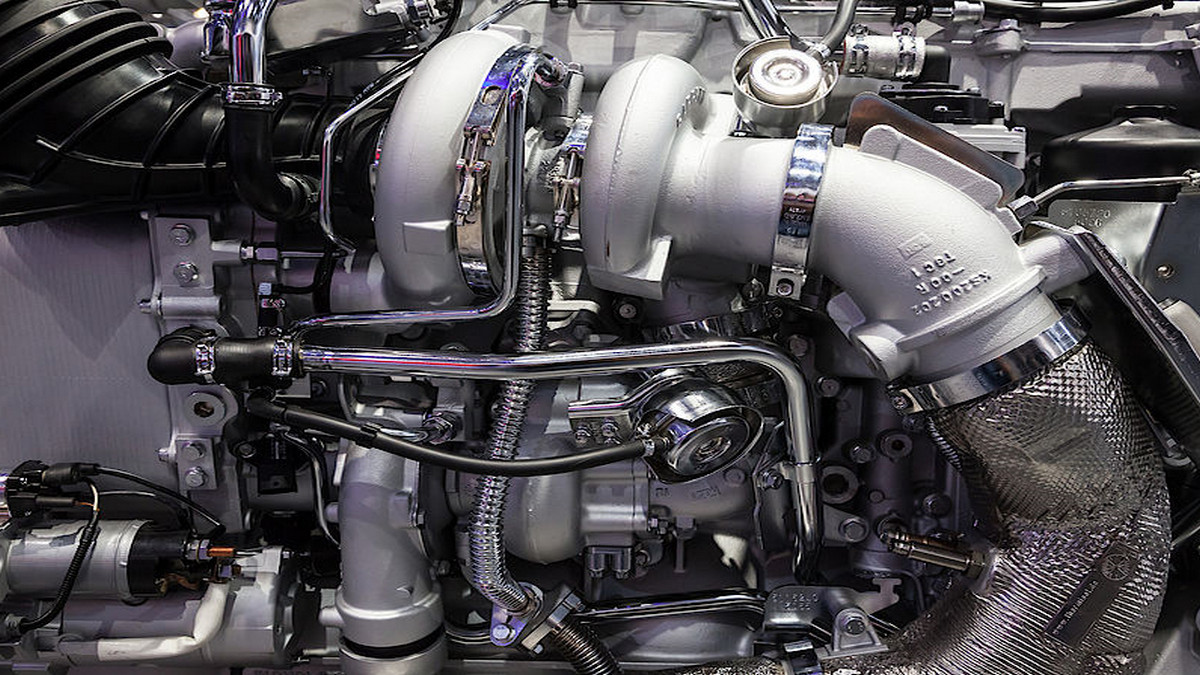

When it comes to the design and manufacturing of advanced equipment used in various manufacturing industries, the importance of CNC lathes and machining centers cannot be overstated. These machines are pivotal in producing high-precision parts for industries ranging from automotive to aerospace, where accuracy, repeatability, and reliability are paramount. In modern manufacturing, plastic injection machines play a critical role in producing high-volume, complex shapes that are fundamental in consumer electronics, automotive, and home appliances. Selecting the right equipment is crucial for success in any industry. Victor Taichung Machinery Works Co., Ltd., established in 1954, has evolved from a traditional lathe manufacturer into a global powerhouse in the machine tool industry. The company specializes in the design and manufacturing of CNC Lathes and Machining Centers, and it uses its own Machining Centers to manufacture its own line of Plastic Injection Machines.

2024-08-16 09:23:52

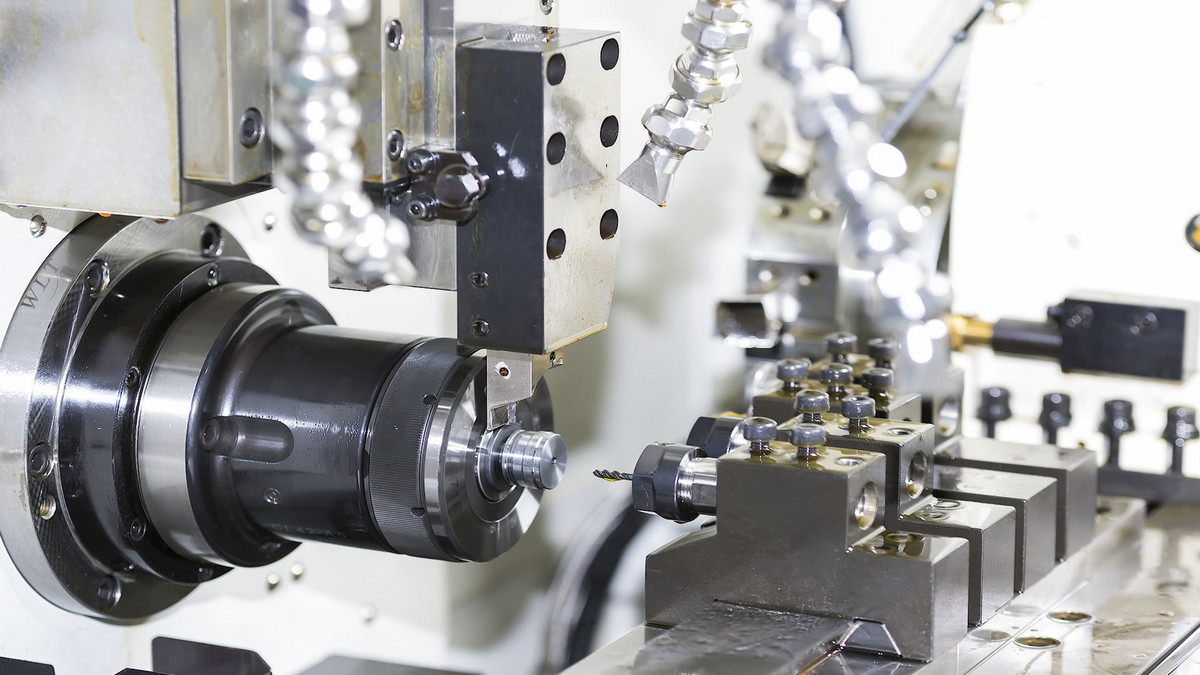

A drilling machine is a machine tool primarily used for making a round hole or driving fasteners. A drilling machine is used for the drilling process, and it is also the processing technology often required in manufacturing production.

2023-05-23 10:40:14

A worm gear is a gear consisting of a shaft with a helical thread that meshes with and drives the gear.

2023-01-04 15:21:29

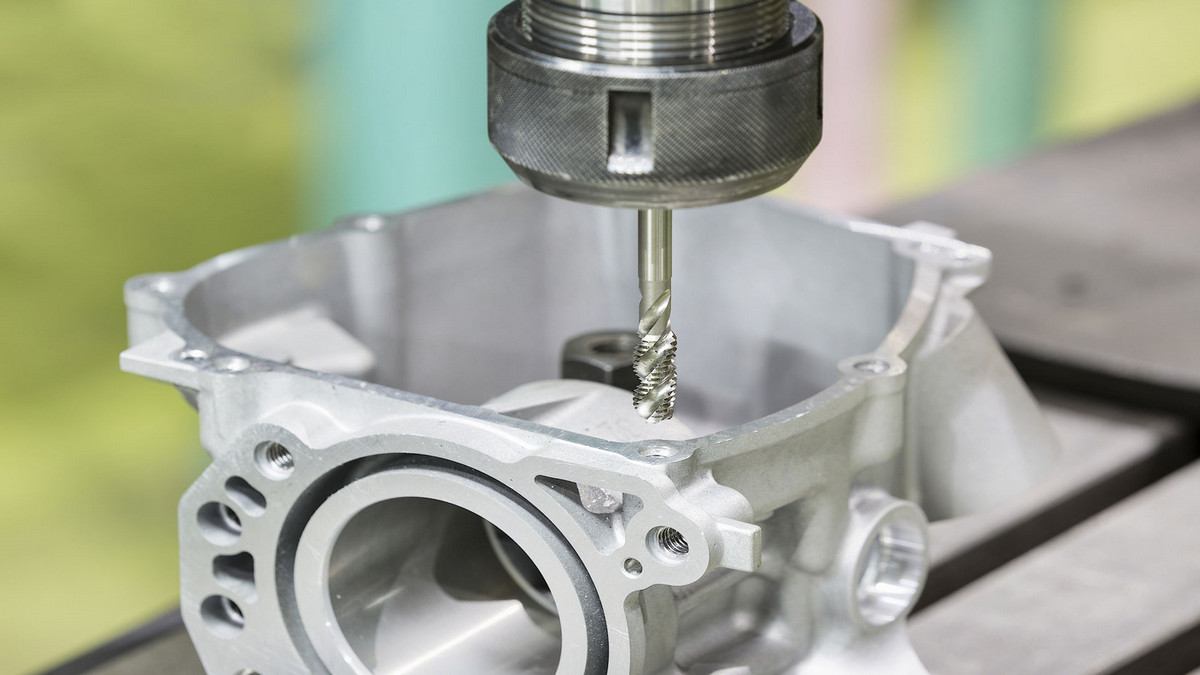

In the chip formation process, materials are cut through mechanical means by using tools like milling cutters, saws, and lathes. It is an integral part of the engineering of developing machines and cutting tools.

2023-01-03 10:25:35

A grinder is a widely used abrasive processing process in which a spinning wheel is covered with coarse grains. Cutting pieces of metallic or non-metallic substances from a workpiece to make the surface flat or smooth.

2022-12-28 17:14:24

Collet is a cylindrical fixture used to install a drill bit or a milling cutter on a milling machine. It is a fixing device used to fix and reinforce parts that need to be modified.

2022-12-23 14:53:56

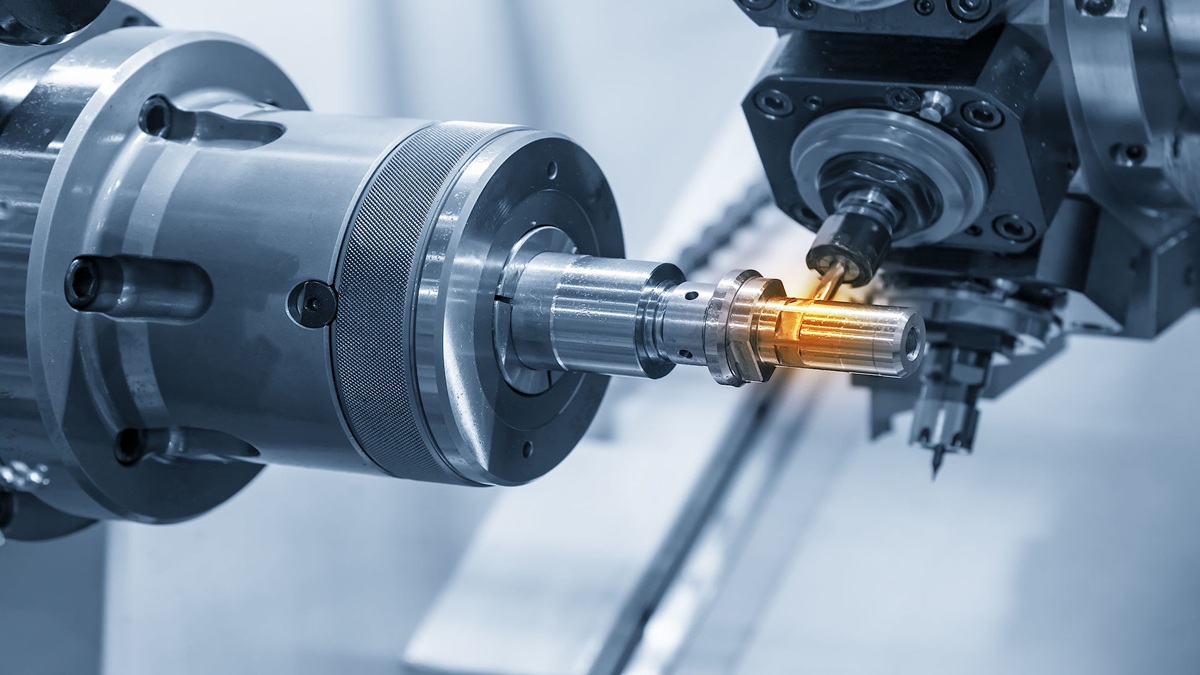

Shaft parts are one typical part of machining. The shaft part is a rotating part whose length is greater than the diameter, and its surface is several outer cylindrical surfaces, conical surfaces, holes, and threads of the same axis.

2022-12-13 13:58:35

Milling machines have better chip evacuation because of the nature of their configuration because gravity keeps the chips from falling. This helps improve the surface finish and prolongs the life of the tool.

2022-12-13 09:23:48

Drilling machines perform different operations as the manufacturing process involves holes to be completed. Different drills must be required for each type of work.

2022-12-12 13:20:03

Different types of milling cutters can be used to cut large amounts of material and leave poor surface smoothness (roughing) or to remove smaller amounts of material but leave good surface smoothness (finishing).

2022-10-27 17:51:51

In pipeline construction, the elbow is a commonly used pipe fitting. Because the construction environment is different, the use environment that the pipeline component will face is different, so the types of elbows are also various. There are strict requirements in the processing of elbows. If the processing environment is affected, there will be certain defects after the final elbows are formed, which will affect the quality of the project.

2022-10-05 09:54:40

The Southeast Asian Manufacturing Alliance, initiated by Singapore, is mainly characterized by orderly and divided industrial zone planning. Singapore is a market entry hub and a high-tech development center.

2022-09-07 13:44:36

Agree