In pipeline construction, the elbow is a commonly used pipe fitting. Because the construction environment is different, the use environment that the pipeline component will face is different, so the types of elbows are also various. There are strict requirements in the processing of elbows. If the processing environment is affected, there will be certain defects after the final elbows are formed, which will affect the quality of the project.

How Much do you Know about Pipe Bending?

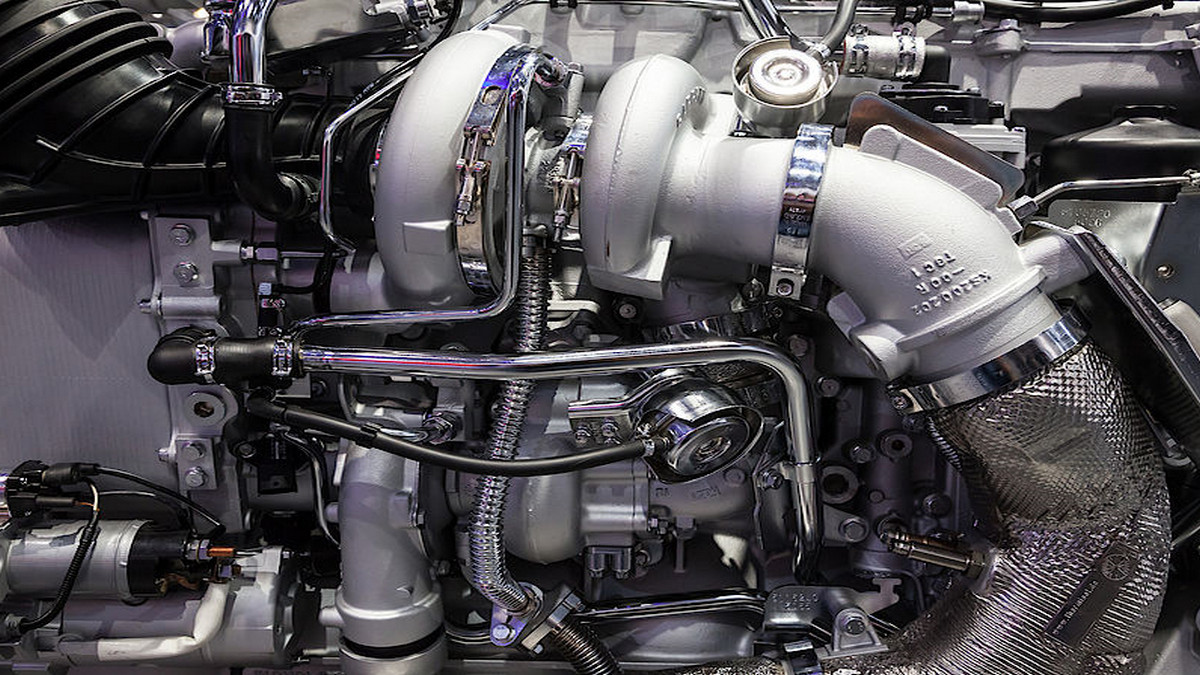

With the rapid development of the regulated industry, the pipe bending process is widely used in electric power, petroleum, marine, chemical, and other fields, mainly for oil transportation, natural gas transportation, and infusion. It plays an important role in aircraft and its engines, so the standards and procedures for pipe bending are important.

In the process of pipe bending, it is necessary to use some very advanced technical means to analyze the pipe material. Of course, in addition to this, the production management system must also be strict, so that excellent pipe bends can be produced. When processing elbows, once the temperature control fails to meet the requirements, the product itself will be damaged and micro-cracks will occur. Therefore, the production management system must effectively control the temperature to avoid the occurrence of unreasonable temperatures.

The generation of micro-cracks has a great impact on the elbow. Once the micro-cracks cannot be controlled during production, they may cause damage to the elbow body. The reason for cracks is often because the heat treatment of the product is not reasonable during production, so the produced elbow will have micro-cracks. Therefore, in the production process, the heat treatment must be strictly controlled to avoid stress cracks.

What is the Bending Process?

Press bending is a process method for pipe bending. It uses a mold to bend the pipe blank on a hydraulic press. The bending has the advantages of simple mold adjustment and high production power, so it has been used in production, generally used for bending straight sections or bending heads pipe fittings.

- Die forging: For small-sized pipe fittings such as socket welding and threaded tees, crosses, elbows, etc., the shape is more complex, and should be manufactured by the die forging process. When the wall tube or plate is made of steel ingots, the steel ingots should be rolled into strips in advance or used as die forging blanks after forging to eliminate segregation, porosity, and other defects in the steel ingots. After heating, put the blanks into the forging die. The pressure causes the metal to flow and fill the mold cavity. If flashing occurs after blank die forging, the remaining flashing material needs to be washed away to complete all die forging work.

- Free forging: Pipe fittings with a special shape or not suitable for die forging can be manufactured by the free forging process. The general shape of pipe fittings should be free forged, such as tee branch pipe should be forged.

- Cutting processing: For some tubular fittings, such as double socket joints, unions, etc., they can be directly processed with bars or thick-walled pipes. During the processing, the fiber flow direction of the metal material should be roughly the same as the axis of the pipe fittings. For tees, crosses, elbows, and pipe fittings, direct cutting of bars is not allowed.

What is the Forming Limit of Elbow Fittings?

- The maximum elongation deformation in the tensile deformation zone outside the neutral layer does not exceed the allowable plasticity value of the material to cause rupture.

- In the compression deformation zone inside the neutral layer, the part of the thin-walled structure subjected to tangential compressive stress will not wrinkle beyond the instability.

- If the pipe fittings have requirements for ovality, control the distortion of the section.

- If the pipe fittings have the strength required to withstand the internal pressure, control the forming limit of the wall thickness reduction.

What is a Pipe Bender?

A pipe bending machine refers to the machine used for pipe bending and can also be used as a jack. It is roughly divided into CNC pipe bending machines, hydraulic pipe bending machines, etc.

Pipe bending machines can be roughly divided into CNC pipe bending machines, hydraulic pipe bending machines, and so on. Mainly used for electric power construction, highway and railway construction, boilers, bridges, ships, furniture, decoration, and other aspects of pipeline laying and repairing. It has the advantages of multiple functions, reasonable structure, and simple operation.

Pipe bending machine classification:

- Classified by power type: hydraulic pipe bender, electric platform pipe bender, pneumatic pipe bender, manual pipe bender, etc.

- Classified according to the control method: CNC pipe bending machine, semi-automatic pipe bending machine, automatic pipe bending machine, etc.

- Classified according to the type of work: single-head pipe bender, double-head pipe bender, multi-head pipe bender, etc.

Pipe bender structure:

- The pipe bending machine adopts a touch screen and a numerical control module, which is operated conversationally, and the program setting is simple and easy.

- The bed structure is stable and not easy to deform.

- Each file can set 16 elbow angles, and the memory can store 16 sets of files.

- All functions of slow positioning, stable bending angle, and repeatability of ±0.1°.

- The error message is displayed on the screen to help the operator to eliminate it immediately.

- Provide self-developed coordinate conversion bending processing value. The software can be installed on the desktop computer for editing and calculation.

What are the Matters that Should be Observed in Pipe Bending?

Pipe bending plants usually place some curved pipes to be processed or processed. Due to the general process, the produced pipes are straight, so almost all curved pipes are processed. When processing piping, the following safe operating procedures should be followed:

- When bending the pipe, it must be processed by the relevant standards and regulations. No matter what the degree of bending is, there must be no instability.

- The processing materials of the elbows need to be inspected and qualified. Bending frames, connectors, and fasteners with defects such as deformation and cracks shall not be used. The fasteners and connectors of the elbows shall not be repaired by welding.

- The foundation ground of the elbow must be flat, tamped, and hard, and its metal bottom plate must be flat and not deformed. When the ground is soft, it is necessary to use a sweeping rod or a backing plate to increase the bearing surface and increase stability.

- The springboards on the elbows need to be laid neatly with the same width and length. The springboards on any pipelines need to be firmly fixed, and there should be no large holes on the surface of the platform.

Before operation:

- The machine tool must be well grounded, and the wire should not be less than 4mm copper flexible wire. It is not allowed to connect to the power supply voltage exceeding the specified range, plug and unplug the plug-in under power, and do not test the control circuit with a megohmmeter. Otherwise, the device may be damaged.

- When inserting and unplugging the connector, do not pull out the wire or cable to prevent the welding from pulling off.

- Proximity switches, encoders, etc. cannot be hit by hard objects.

- Do not hit the display unit with sharp objects.

- The electrical box must be placed in a ventilated place, and it is forbidden to work in dust and corrosive gases.

- Do not install or change the PC input and output terminals without permission.

- When changing the power supply of the machine tool, the direction of the motor must be reconfirmed.

- The machine tool should be kept clean, and special attention should be paid to the fact that there should be no foreign objects in the sliding grooves such as clamping blocks and sliders.

- Regularly add lubricating oil to the chain and other sliding parts.

- The power must be disconnected during cleaning and maintenance.

- Preparation before starting: Check whether the oil level of the fuel tank reaches the oil level line, add oil to each lubricating point, start the machine to confirm the rotation of the motor, check whether the oil pump has any abnormal sound, and check whether there is oil leakage in the hydraulic system after starting the machine.

- Pressure adjustment: Adjust the pressure with an electromagnetic relief valve to ensure that the system pressure reaches the required working pressure, generally not higher than 12.5Mpa.

- Die adjustment: Die installation requires that the die and the clamping block be centered, and the clamping block can be adjusted with bolts. The booster block is aligned with the mold, and the booster block is adjustable. Center the core head and the mold, loosen the bolts of the core head frame and tighten the bolts after adjusting the center.

In operation:

- When the machine tool is started, pay attention that the human body should not enter the range swept by the rotating arm.

- When the machine tool is working, all personnel are prohibited from entering the space swept by the rotating arm and the pipe fittings.

- The hydraulic system of the machine tool adopts ordinary hydraulic oil, which should be replaced once a year under normal circumstances, and the oil filter must be cleaned at the same time.

- When adjusting the tool mold, the adjuster should press the button to adjust. Never adjust the machine tool by one person and operate on the control cabinet by another person.

- Remove the mandrel when adjusting the machine tool or driving empty.

- The hydraulic system pressure should not be greater than 14Mpa.

- When manually adjusting the speed of the side push cylinder, the arm should be rotated to ≥ 900. The adjustment speed should be synchronized with the line speed of the edge of the bending die.

- The tightness of the chain should be checked after the machine has been used for a while, and the tightness of the upper and lower chains should be kept consistent.

- In automatic operation in the core bending mode, before the bending arm returns, the operator must ensure that the core head is in the pipe or ensure that the mandrel is not blocked when the bending arm returns. Otherwise, the core head or core rod may be broken. bent or broken.

After operation:

- Turn off the power.

- Do a good job of cleaning and lubrication.

.jpg)

.png)