Shaft parts are one typical part of machining. The shaft part is a rotating part whose length is greater than the diameter, and its surface is several outer cylindrical surfaces, conical surfaces, holes, and threads of the same axis.

What is the Spindle?

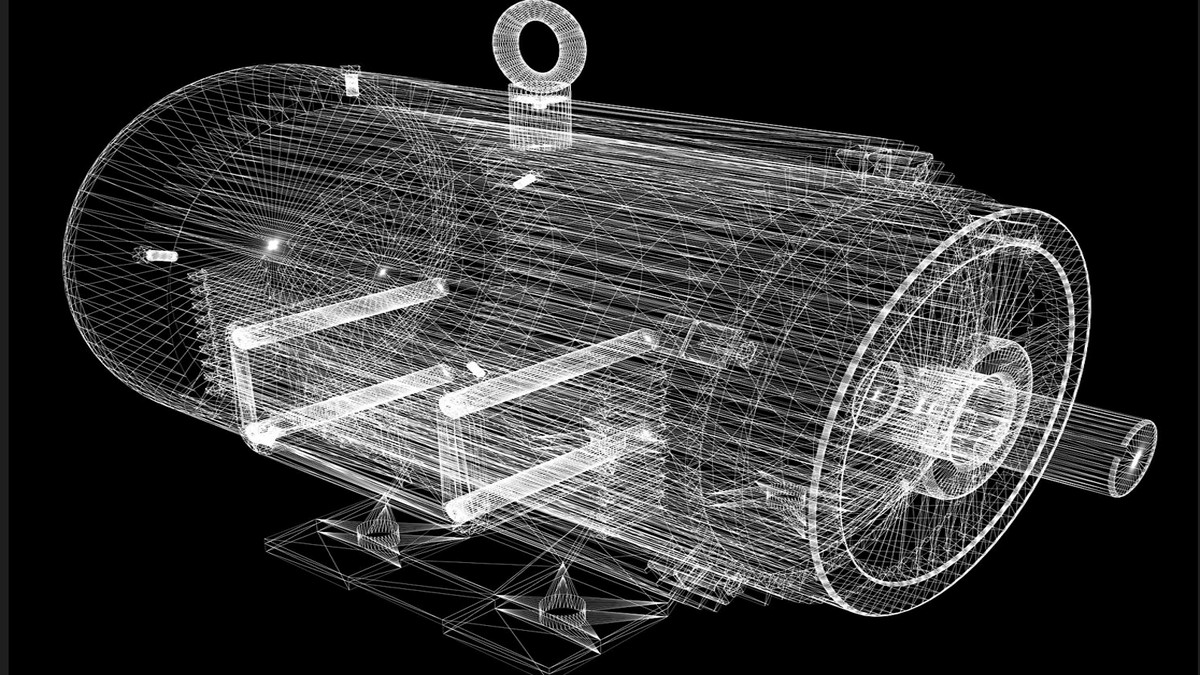

The machine tool spindle is a typical shaft part. It is one of the key parts of the machine tool. It transmits the rotary motion and torque to the workpiece or tool through the furniture at the end of the spindle. The spindle must bear torque and bending moment during work, and it requires high rotation accuracy. The manufacturing quality of the spindle will directly affect the working accuracy and service life of the entire machine tool. A series of technical requirements are stipulated on the spindle part drawing, such as dimensional accuracy, shape position tolerance, surface roughness, contact accuracy, and heat treatment requirements.

The mechanical spindle refers to the axis on the machine tool that drives the workpiece or tool to rotate. The spindle part is usually composed of the spindle, bearings, and transmission parts. The machine is used to support transmission parts such as gears and pulleys to transmit motion and torque. The motion accuracy and structural rigidity of the spindle components are important factors that determine the processing quality and cutting efficiency. Most machine tools have multiple axes, such as headstock and tailstock on lathes. The largest axis in a machine tool is generally the spindle. Some machine tools can perform more processes, and there may be four, six, or even more spindles. The kind of machine tool is a multi-axis machine tool. For example, row drills and many screw machines are multi-axis machine tools. Although the automatic lathe has two axes, the head shaft, and the tail shaft, only the head shaft is the spindle, so it is still a single-axis machine tool.

The main function of the spindle:

- Ensure the rigidity of the support.

- Guarantee rotation accuracy.

- Connection function.

- Wear resistance of the inner cone and end face.

- Static balance and dynamic balance of the spindle assembly.

The Function and Technical Requirements of Each Part of the Spindle:

- The spindle support journal is used to install the support bearing and is the assembly reference plane of the spindle, its manufacturing accuracy directly affects the rotation accuracy of the spindle.

- Accuracy of the working surface of the spindle refers to the centering surface of the clamping props or furniture, such as the Morse taper hole, the outer cone of the shaft end, or the outer circle of the flange, etc. The dimensional accuracy, geometric shape accuracy, and contact accuracy of the inner and outer tapered surfaces, the coaxially of the centering surface to the bearing journal, the perpendicularity of the positioning end to the axis of the journal, etc. Their influence on the working accuracy of machine tools can cause clamping errors in furniture or workpieces. The radial runout near the end of the spindle and the radial circular runout from the end face are specified in the technical requirements of the spindle. In addition, to ensure good contact and fit of the taper shank of the taper hole jade top fire tool. It is stipulated that the contact area must be inspected by the standard taper plug gauge and the coloring method.

- The accuracy of the spindle secondary journal and other surfaces the spindle secondary journal refers to the surface where gears, bushings, and other parts are assembled. When the end face of the adjusting nut runs out, it will cause the pressed bearing ring to tilt, thereby increasing the radial runout of the spindle. This will not only affect the machining accuracy of the workpiece but also reduce the bearing life.

- The surface roughness of each spindle is different. The surface roughness requirements of each surface of the spindle of the machine tool are as shown in the standard.

- Hardness of each surface of the spindle the journal surfaces, working surfaces, and other sliding surfaces of the spindle will be subject to different degrees of friction. In the cooperation of sliding bearings, the friction between the journal and the bearing pad requires high wear resistance on the surface of the journal, and its hardness can vary depending on the material of the bearing pad. In the rolling bearing fit, the friction is borne by the bearing ring and the rolling body, so the journal does not require high wear resistance, but it still requires an appropriate increase in its hardness to improve its assembly process and assembly accuracy.

Spindle Performance Index:

- Rotation accuracy: The radial and axial runouts that occur in the direction that affects the machining accuracy when the spindle rotates are determined by the manufacturing and assembly quality of the spindle and bearings.

- Dynamic and static stiffness: Mainly determined by the bending stiffness of the spindle, the stiffness, and the damping of the bearing.

- Speed adaptability: The allowable maximum speed and speed range are determined by the structure and lubrication of the bearing, as well as the heat dissipation conditions.

Mechanical Spindle Maintenance:

- When using oil circulation lubrication, it is necessary to ensure that the amount of oil in the constant temperature oil tank of the spindle is sufficient.

- The oil-air lubrication method is just opposite to the oil circulation lubrication. It only needs to fill 10% of the bearing space capacity.

The advantage of circulating lubrication is that it can reduce frictional heating and absorb part of the heat of the spindle assembly when lubrication is satisfied. There are also two types of lubrication for the spindle: oil mist lubrication and injection lubrication.

Mechanical Spindle-related Knowledge:

The oil used in oil mist and oil-air lubrication is generally turbine oil. The oil mist or oil-air lubrication system should be turned on before the spindle of the oil-lubricated machine tool starts to run, and the lubrication system should be turned off after the spindle stops. Water cooling is a common way to cool the spindle. It requires the cooling water to have a certain anti-rust function. If necessary, it is required to properly filter the cooling water. Before the spindle is running, the cooling system should be turned on to cool the spindle. The machine tool spindle can be used at reduced speed, but the corresponding input voltage parameters must be adjusted according to the design characteristic curve of the motor. A spindle lubricated by oil mist or oil-air needs to ensure that the compressed air is dry and clean.

The parameters of the spindle are different, and the requirements for the frequency converter are also different. The frequency converter should be selected to match the parameters of the machine tool spindle, and the rated current of the frequency converter should be at least 1.3 times that of the machine tool spindle, preferably more than 1.5 times. Commonly used lubrication methods for spindles include grease, oil mist, and oil air. Grease lubrication is simple in structure, easy to use, and environmentally friendly. Oil mist lubrication can adapt to higher speeds and is the most widely used, but it has an impact on the environment. Oil-air lubrication has the best effect, can adapt to higher speeds, and has no pollution to the environment, but the price of oil-air lubrication devices is relatively high.

Mechanical Spindle Accelerator:

The speed regulation range of mechanical spindle accelerators varies from 3.5 to 8 times, depending on the manufacturer of the accelerator. Only one manufacturer offers a mechanical spindle speed booster that can increase machine speed by a factor of 10, delivering 2kW of power at a maximum overspeed of 40,000rpm. The spindle is one of the main components of the machining center because its design directly affects the machining efficiency and workpiece quality. Therefore, the spindle design must consider the static and dynamic stiffness, shaft diameter, bearings, design parameters, etc. The performance of the machine tool spindle accelerator mainly depends on the optimal design for the required speed and power transmission ratio. In particular two factors have to be taken into account because they are important in the optimal design of the spindle speed control unit, these two factors are the smallest volume and the smallest transmitted kinetic energy.

To save weight, the volume of the spindle speed control unit must be minimized without reducing the space required for the operation of the machine tool. Mechanical spindle speeders must be designed for long-term production work, and therefore, the transmitted kinetic energy must be minimized to ensure optimum performance. The design of the spindle governor has led to the use of transmissions based on planetary gear sequences (PGTs), as planetary gear sequences, PGTs provide a compact and efficient solution with high speeds and high efficiency. PGTs are used in many machines equipped with automotive gearboxes to extend the constant power range of low-speed spindle drive motors for machine tools.

.jpg)

.png)