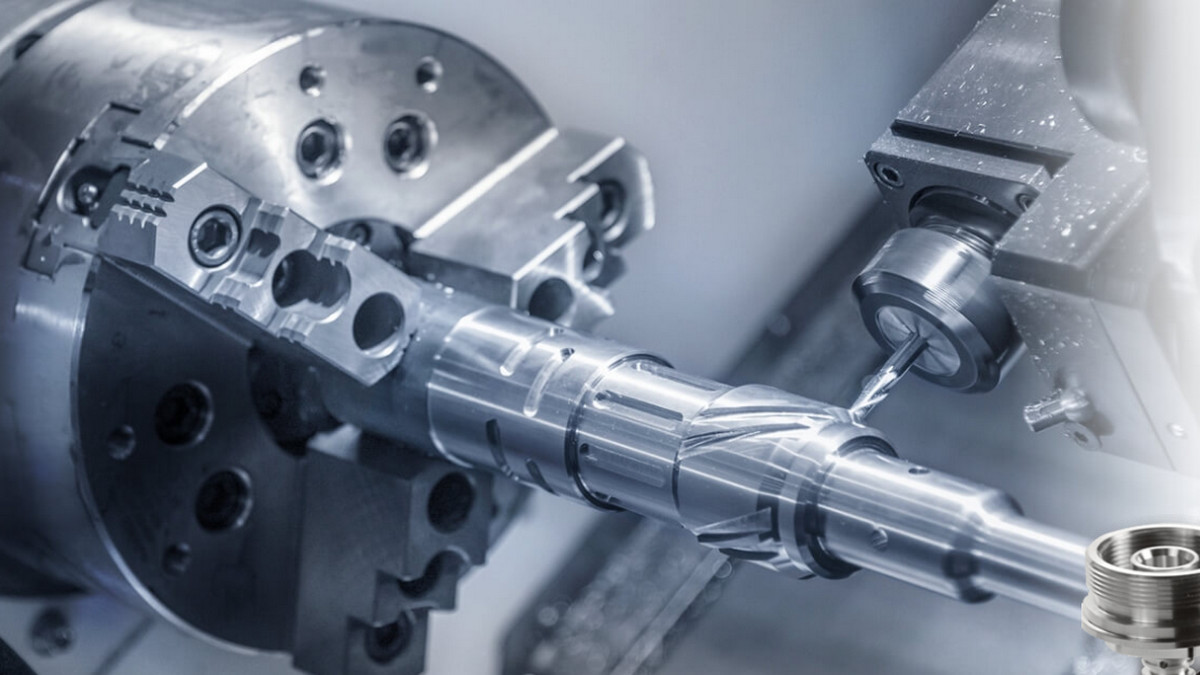

In the world of precision machining, Yung Cheng Shun has emerged as a trusted provider of CNC machining services. Established in 1987, the company has continually evolved to meet the demands of various industries, including medical, electronics, optics, automotive, and bicycle manufacturing. With a strong emphasis on quality control and advanced machining technologies, Yung Cheng Shun has become synonymous with precision, efficiency, and cost-effectiveness.

In the world of precision machining, Yung Cheng Shun has emerged as a trusted provider of CNC machining services. Established in 1987, the company has continually evolved to meet the demands of various industries, including medical, electronics, optics, automotive, and bicycle manufacturing. With a strong emphasis on quality control and advanced machining technologies, Yung Cheng Shun has become synonymous with precision, efficiency, and cost-effectiveness.

Diverse Machining Capabilities:

Yung Cheng Shun specializes in the production of CNC-machined parts for a wide range of applications.

Medical Equipment Parts:

One of their notable areas of expertise lies in the machining of

medical parts for medical machines. The manufacturing of such components requires utmost precision and adherence to strict standards. Yung Cheng Shun ensures the highest level of quality control by employing advanced and accurate optical projectors and electronic measuring instruments, including renowned German ZEISS three-dimensional measuring instruments.

Electronics and Optics:

The electronics and optics industries demand intricate and

high-quality components. Yung Cheng Shun specializes in meeting these

requirements by leveraging state-of-the-art Japan machining tools, such as those manufactured by Miyano, and Nakamura, and Mazak companies, and utilizing cutting-edge machining processes. Their expertise enables them to produce parts with precise dimensions, smooth surfaces, and excellent repeatability, critical for optimal functionality in electronic and optical devices.

Automotive and Motorcycle Parts:

Yung Cheng Shun provides comprehensive CNC machining services for

the automotive and motorcycle industries. From manufacturing refrigerant fittings and hydraulic fittings to producing parts for brake systems, transmission systems, and shock absorbers, the company offers customized solutions to meet specific requirements. By utilizing advanced composite CNC automatic lathes, Yung Cheng Shun ensures efficient and accurate production of high-quality automotive and motorcycle components.

Bicycle Parts:

Yung Cheng Shun's focus on producing various high-quality bicycle parts, including forks, shock absorbers, hydraulic fittings, headsets, and spindles, highlights their expertise in the cycling

industry. By combining precision machining techniques with cutting-edge tools, the company delivers bicycle components that exhibit exceptional performance, durability, and aesthetics.

Precision Axis Screws:

Yung Cheng Shun also offers precision axis screws, a crucial

component in various machinery and equipment. These screws play a vital role in ensuring smooth and precise linear motion. The company's expertise in manufacturing precision axis screws enables them to provide customized solutions tailored to the specific requirements of their clients.

When it comes to CNC manufacturing, certain considerations are

paramount for ensuring the successful production of high-quality parts. Yung Cheng Shun understands these requirements and implements the best practices in their manufacturing processes. Some of the key considerations include:

Material Selection:

Choosing the appropriate material is crucial for achieving desired

strength, durability, and functionality. Yung Cheng Shun works closely with clients to select the most suitable materials for their specific applications.

Surface Treatment:

Yung Cheng Shun recognizes the importance of surface treatment and

offers a range of options to match the requirements of different parts. This includes coatings, plating, polishing, and other surface finishing techniques.

Precision and Tolerance:

Meeting precise specifications and tight tolerances is essential,

especially for medical, electronics, and optics parts. Yung Cheng Shun utilizes advanced machining tools and employs skilled technicians to ensure precise machining with high accuracy.

Enhancing Quality and Efficiency:

To ensure the production of CNC machined parts of superior quality, Yung Cheng Shun follows rigorous quality control processes. By investing in advanced inspection and measuring instruments, the company carefully examines incoming materials, manufacturing processes, finished products, and shipments. This commitment to quality has led Yung Cheng Shun to achieve ISO 9001:2015 quality certification, reinforcing their dedication to excellence.

From traditional methods such as lathes, planers, milling machines, and grinding machines to non-traditional techniques like laser machining, EDM, and waterjet machining, Yung Cheng Shun employs the most suitable methods for each project. This versatility allows them to achieve precise and efficient manufacturing while optimizing cost-effectiveness.

Yung Cheng Shun -Your Cutting-edge CNC Machining Service Provider

With their extensive experience,

state-of-the-art equipment, and commitment to quality, Yung Cheng Shun excels in delivering precision-machined parts for various industries and continues to meet the diverse needs of its clients while striving for excellence in every aspect of CNC manufacturing.