Global energy costs continue to rise alongside stricter carbon emission regulations worldwide, motivating manufacturers to pursue sustainability and energy efficiency. Traditional hydraulic systems consume high energy and incur significant operating costs, increasing enterprise burdens and hindering production line modernization. AnyPower Hydraulic Industry Co., Ltd. has independently developed a servo energy-saving hydraulic unit precisely designed to meet these market demands, providing key solutions for partners to achieve energy savings and sustainable growth.

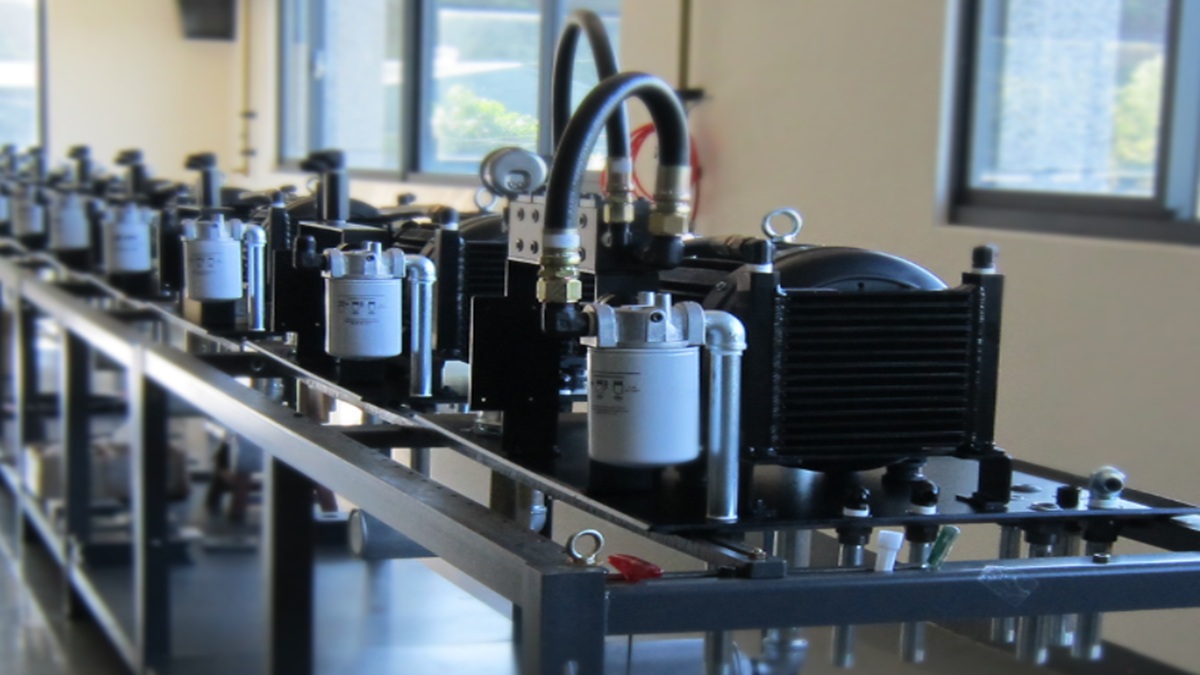

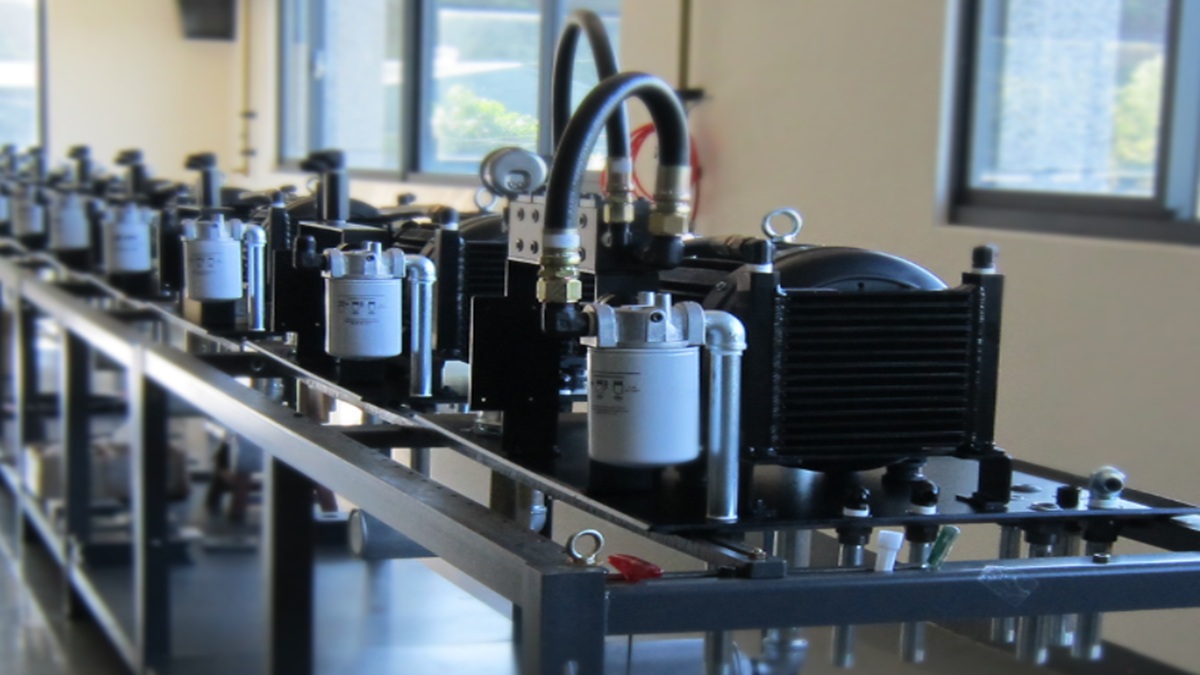

Photo by https://www.anypower-mit.com/

Industry Energy-saving Upgrade Trends

The manufacturing sector urgently needs next-generation energy-saving solutions to replace inefficient, high consumption traditional hydraulic systems. Servo technology—with precise dynamic control and high efficiency—has rapidly become standard in CNC machines and machining centers, propelling the industry toward energy-efficient and intelligent green manufacturing.

AnyPower’s servo energy-saving hydraulic unit integrates a variable frequency drive with a high-efficiency permanent magnet motor to dynamically adjust pressure and flow based on production needs, ensuring both energy efficiency and system stability.

Key Technical Indicators:

- Average power consumption per hour: 0.16 kWh, 76% less than traditional 0.68 kWh

- Oil temperature rise below 5 °C, reducing cooling and maintenance demands

- Noise level below 60 dB, improving workplace environment

- Vibration less than 5 μm, guaranteeing production precision

- Response time of only 0.01 seconds, meeting diverse process needs

- Patented and certified for energy-saving in Taiwan and Japan

Data Speaks: Measured Benefits and Long-Term Value

Over 4,088 rigorous hours of testing, AnyPower’s servo energy-saving hydraulic unit averaged 0.16 kWh power consumption per hour—significantly lower than the traditional system’s 0.68 kWh. This exceptional performance saves energy and substantially lowers operational costs, delivering long-term benefits:

- Reduced carbon emissions supporting ESG objectives

- Extended service life due to stable oil temperatures, lowering maintenance frequency

- Improved total cost of ownership (TCO) through combined savings on energy and maintenance, enhancing competitiveness

These data and results are based on official rigorous testing. Details available at : Official 4,088-hour operation test results

Empowering Corporate Competitiveness and Growth Potential

Implementing AnyPower’s servo energy-saving hydraulic unit achieves significant energy savings and strengthens enterprise competitiveness by:

- Complying with international standards and ESG requirements, facilitating entry into green supply chains

- Stable operation and low failure rate ensures efficient production and reduces downtime

- Building a responsible, future-oriented brand aligned with sustainability trends

- Integrating remote monitoring and data feedback for predictive maintenance and production optimization, assisting in proactive smart manufacturing planning and market opportunity capture

Details : AnyPower Hydraulic Industry Co., Ltd.

Key Driver of Green Manufacturing

As global manufacturing accelerates energy-efficient and intelligent transformation, AnyPower’s servo energy-saving hydraulic unit—with outstanding energy-saving efficiency and system stability—has become a key driver of industry upgrades and sustainable growth. Supported by stringent testing and multiple patents, we are dedicated to helping you reduce energy costs and elevate production competitiveness.

We sincerely invite you to contact AnyPower’s professional team to customize your energy-saving solution and seize leadership in smart manufacturing.