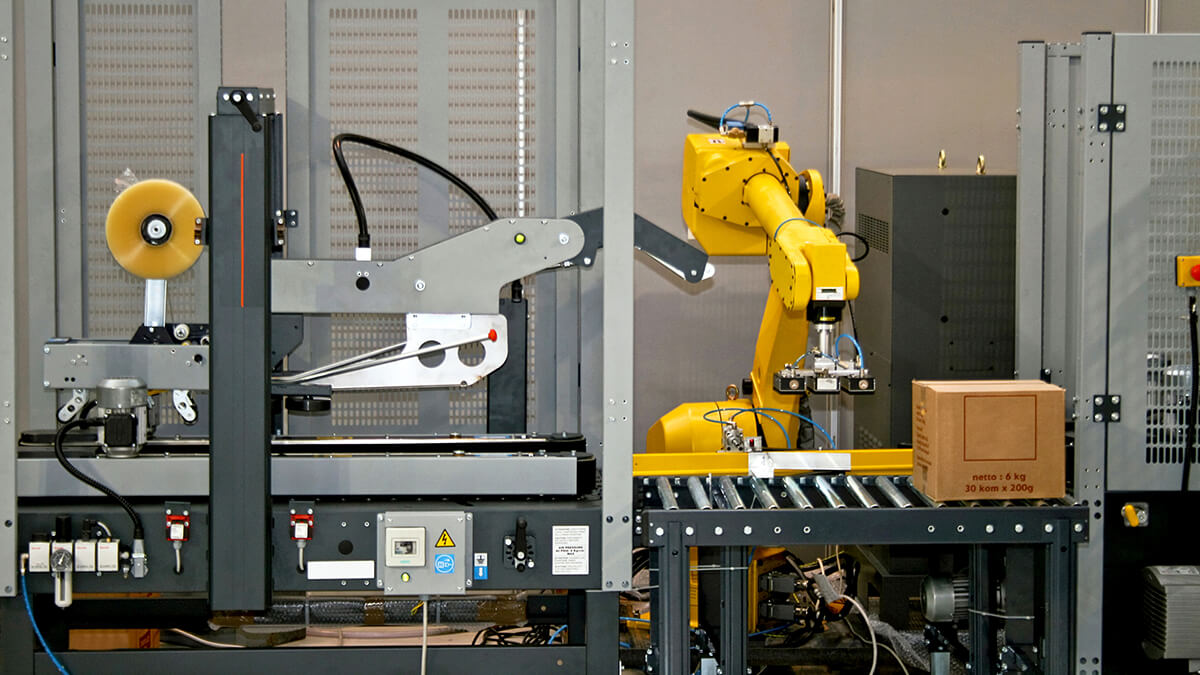

Nowadays, the traditional industry combines the technology of the Internet of Things, towards the innovation of Industry 4.0 and the development of intelligent manufacturing.

The global industrial automation market is expected to reach $32.93 billion by 2024. The automation of the automotive industry is expected to be one of the major contributors to the global industrial market.

Industry 4.0 provides a new impetus and operating model for the manufacturing industry, transforming industries in ways never before possible. In fact, one of the core parts of this new concept of Industry 4.0 is automated manufacturing. According to a report by Zion Market Research, it is estimated that by 2024, the global industrial automation market will reach $321.93 billion. The report further adds that by the end of 2024, the market is expected to generate approximately $32.93 billion in revenue, with a compound annual growth rate of approximately 6.5% between 2018 and 2024. This is not surprising, as almost all industries are now using automation extensively in their processes to increase productivity, maintain high quality, flexibility, information accuracy, low cost and security, all of which are advantages of the automation market.

Automation of the Automotive Industry

Whether it is using smart solutions or using IIoT (Industrial Internet of Things), the automotive industry has long been dominated by automation. Many well-known automakers such as Tesla, Volkswagen, BMW, and Toyota are already using a range of automation technologies. Some notable automation solutions used in the automotive sector include cognitive computing in cobots and IoT connected cars.

What is Cobots Robots?

These robots work on machine learning and work independently without human intervention, light weight and portability. Cobots robots help to produce high quality products with the highest precision. This will be one of the trends in the future development of industrial automation.

Cognitive Computing in IoT Networked Connected Cars

Cognitive computing is an AI-based platform that leverages concepts such as machine learning, human-computer interaction, and human language processing. German car-maker BMW is exploring the idea of using cognitive computing and the Internet of Things to create autonomous cars. These cars are expected to communicate with each other while recognizing the driving patterns of their human drivers in emotional situations. If successfully tested, these self-driving cars will become an advanced version of driver-less cars.

Conclusion

Industry 4.0 continues to drive the global industrial automation market, with the automotive industry playing a vital role in its transformative journey. As automation becomes increasingly prevalent across sectors, industries can anticipate heightened productivity, efficiency, and innovation, further reshaping the future of manufacturing.

.jpg)