In today's era where digital education and maker learning are prevalent, the design of teaching tools is no longer limited to static displays but is moving toward interactivity, modularity, and creative expansion. Flexible magnetic materials—especially flexible magnets that can be cut, printed, and adhered—are gradually becoming indispensable media in the new generation of educational settings. These materials can be flexibly applied to puzzle teaching aids, display boards, and modular signage systems. Moreover, due to their ease of processing and cost-effectiveness, they widely support hands-on practice and creative activities in STEAM education (Science, Technology, Engineering, Arts, and Mathematics).

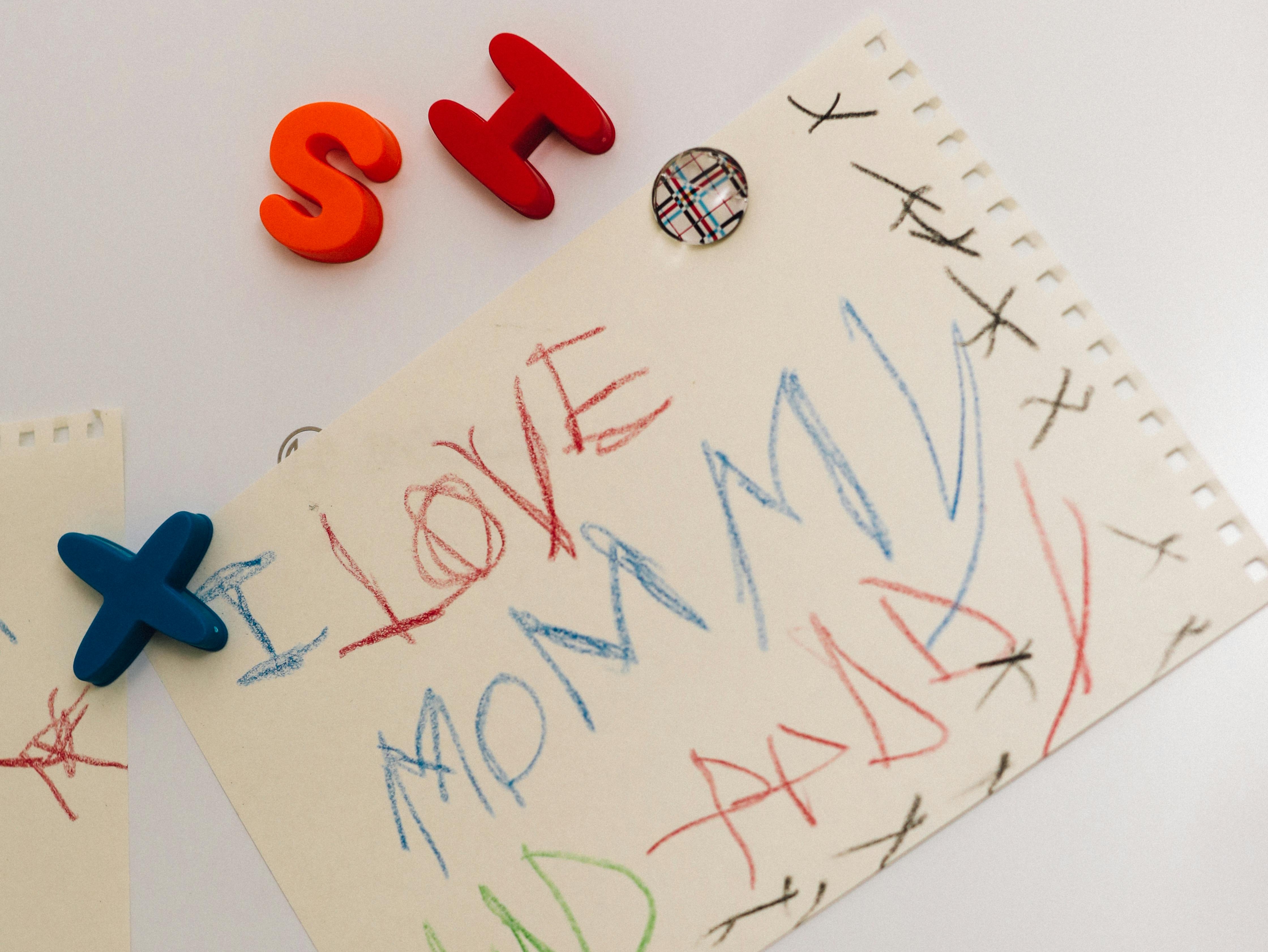

Photo by https://www.pexels.com/zh-tw/photo/6975150/

Flexible Magnetic Materials

Mainly composed of ferrite magnetic powder mixed with synthetic rubber (such as CPE or NBR), these materials are produced by calendering or extrusion, offering good flexibility and stable magnetic force.

Their surfaces can be covered with various functional coatings, including:

- Colored vinyl facing: suitable for visual displays and teaching puzzles

- Printable paper layer or white PVC: supports printing or whiteboard marker writing

- Pressure-sensitive adhesive backing: can adhere to substrates such as cardboard, plastic, and wood

- Glossy/matte photo paper: suitable for high-quality displays and output

Flexible magnetic sheets and strips can be die-cut into customized shapes and sizes, flexibly accommodating both small-scale handmade and large-scale production. Compared to traditional ceramic magnets, these materials offer greater processing flexibility and economic benefits, making them ideal choices for educational material production, interactive walls, maker puzzles, and DIY display applications.

Key Materials for Interactive Teaching Aids

Modern educational environments increasingly emphasize "hands-on activities" and "spatial interaction." Flexible magnetic products can be cut into various shapes according to teaching scenarios and combined with printed images to create teaching aids or puzzle boards, widely applied in:

- Language and math learning boards

- Reconfigurable world maps and biological charts

- Kindergarten thematic teaching walls

- Special education resource teaching aids

These products not only enhance teaching flexibility but also transform classroom walls into interactive learning spaces.

Ideal Medium for Maker Education and DIY Kits

With the promotion of maker education, schools at all levels have introduced laser cutters, 3D printers, and other equipment. Due to their easy cuttability, compatibility with various materials, and low waste characteristics, flexible magnetic materials have become a popular choice for students designing DIY kits.

For example, students can use flexible magnetic sheets to design magnetic levitation models, science display boards, mechanical puzzles, and more, enhancing creativity and problem-solving skills.

Sustainable Education and the Choice of Low-Carbon Materials

Amid the trend of sustainable education, magnetic flexible materials are evolving toward recyclability and high durability. With features such as reusability and no need for adhesives, these materials not only reduce waste from disposable teaching aids but also lower the frequency of replacement in schools, improving overall carbon footprint efficiency.

Magnetic Materials Are Reshaping Interaction in Educational Settings

he flexible magnet industry is no longer just an extension of “magnets” but a functional material supplier aligned with educational innovation. As customized manufacturing processes and printing technologies mature, flexible magnetic materials will play an increasingly important role in the education market—from early childhood education and special education to maker courses—realizing a high level of integration and flexibility between teaching content and material use.

.png)