Blow molding technology traces its roots back to the ancient art of glassblowing. As early as the 1st century BC, the Phoenicians had already mastered glassblowing techniques. In the early 20th century, this principle was successfully adapted to plastics processing, leading to the creation of the world’s first plastic blow molding machine. From beverage bottles and cosmetic jars to large water tanks and automotive fuel tanks, blow molding enables the efficient and consistent mass production of a wide range of hollow plastic products. These items not only feature uniform wall thickness and lightweight design but also offer durability and functionality. This fusion of ancient wisdom and modern craftsmanship has made blow molding an indispensable core technology in both everyday life and industrial manufacturing.

Breathing Through the Ages, Shaping the Future: Unveiling the Origins of Blow Molding Technology

Blow molding traces its origins to the ancient art of glassblowing. Historical records show that as early as the 1st century BC, the Phoenicians along the eastern Mediterranean coast (modern-day Syria) pioneered glassblowing techniques. At that time, craftsmen would draw molten glass into a blowpipe and rapidly rotate it to shape containers, transforming the production of glass vessels from a labor-intensive manual process into an efficient method for batch manufacturing.

In the early 20th century, this “air-shaping” concept was introduced to plastics processing. In 1938, American inventors Enoch Ferngren and William Kopitke applied the principles of glassblowing to plastics, developing the world’s first plastic blow molding machine and successfully commercializing it. From that point on, blow molding expanded from the glass industry into plastics, becoming a fundamental technology for producing beverage packaging, household items, and a wide range of plastic containers.

The Magic of High-Pressure Air: Revealing How Blow Molding Machines Work

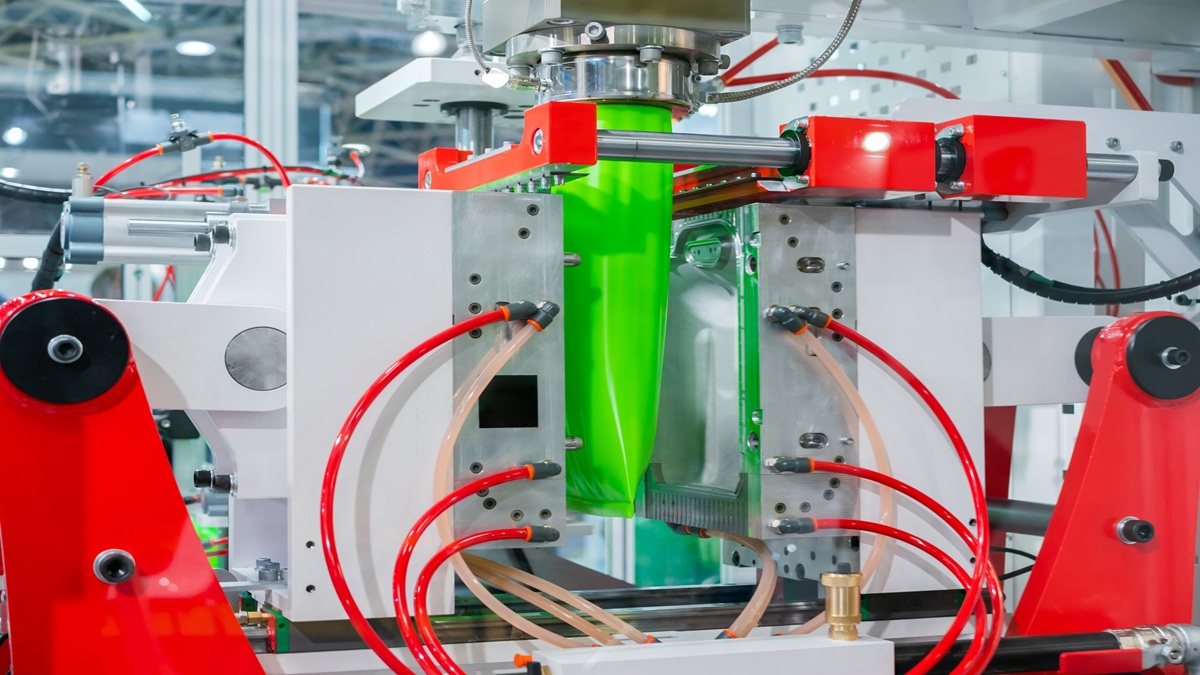

The core technology of a blow molding machine lies in “air shaping.” The typical operation process is as follows: first, the plastic raw material is heated and softened to form a tubular preform, called a parison. The preheated parison is then clamped within a closed metal mold, and compressed air is blown into the tube, causing the softened plastic to rapidly fill the mold cavity. The expanding air presses the plastic firmly against the mold walls, and once cooled and solidified, a hollow plastic product is formed.

Throughout the process, temperature, air pressure, and blowing time must be precisely controlled: if the temperature is too low, the plastic won’t fully expand; if too high, it may degrade. Insufficient pressure leads to uneven wall thickness, while excessive pressure can cause rupture. To ensure consistent quality, modern blow molding machines are typically equipped with precise heating, cooling, and pressure control systems, often integrated with closed-loop control to maintain uniformity across batches.

This technique—using high-pressure air to “blow” a plastic parison into shape—allows blow molding machines to efficiently and reliably produce a wide range of hollow plastic containers.

From Bottles and Jars to Automotive Parts: The Wide World of Blow-Molded Products

Blow molding technology has an extremely wide range of applications, spanning from everyday household items to industrial equipment. Industry reports highlight that blow molding is particularly well-suited for producing various plastic bottles and containers. Examples include beverage bottles, chemical drums, cleaning product bottles, shampoo bottles, cosmetic jars, and even sterile medical vials. Blow molding ensures uniform wall thickness, lightweight yet sturdy construction, making it ideal for holding carbonated drinks or other liquid products.

Beyond small containers, blow molding is also used for larger items such as agricultural irrigation tanks, household water storage tanks, and chemical storage containers. Notably, blow molding plays a significant role in the automotive industry as well: multi-layer blow molding technology is widely applied in manufacturing automotive fuel tanks and air ducts. Modern fuel tanks are often made from multi-layer HDPE, offering a lightweight structure that is not only safe and corrosion-resistant but also helps improve fuel efficiency.

From drinking water bottles to industrial oil tanks, blow-molded products are found in nearly every aspect of our daily environment, demonstrating the versatility and practical value of this technology.

Energy Efficiency and Sustainability: Trends in Blow Molding Machine Design Innovation

With growing global emphasis on environmental protection, modern blow molding machines are making continuous strides in energy saving, emission reduction, and material recycling. The latest equipment commonly replaces traditional hydraulic systems with servo-driven motors, which not only reduce energy consumption but also improve response speed. Industry data show that these advanced servo systems can lower energy usage by approximately 35% to 40%.

Additionally, some manufacturers have integrated closed-loop recycling systems into their blow molding lines, allowing scrap edges or defective plastic to be remelted and reused. Reports indicate that combining energy-efficient features with closed-loop recycling can reduce material waste by nearly 40%, significantly improving raw material utilization.

In terms of materials, many blow molding factories are incorporating recycled plastics, such as reclaimed PET or HDPE, often using formulas with about 30% recycled content. This approach maintains the performance of finished products while helping cut carbon emissions by 30% to 60%.

By combining energy-efficient motors, intelligent controls, and recycling technologies, modern blow molding production not only reduces costs but also gradually moves toward a more sustainable manufacturing model.

Smart Upgrades: The Digital Future of Blow Molding Technology

The move toward smarter and more connected blow molding factories is now widely recognized. With the advancement of Industry 4.0, IoT sensors, cloud data, and artificial intelligence are gradually being integrated into blow molding machines. By deploying sensors along production lines to monitor temperature, pressure, and flow, management systems can track critical parameters in real time and use AI algorithms for trend analysis and predictive insights.

Reports from the plastics industry indicate that some large material manufacturers have implemented AI platforms that allow machines to autonomously learn process parameters and predict equipment failures. When potential issues are detected, the system issues early warnings and schedules maintenance, maximizing production line uptime. At the same time, digital management aids in quality control: AI and IoT technologies enhance production efficiency, reduce downtime, and maintain consistent product quality.

Looking ahead, blow molding machines will become an integral part of smart factories. Technologies such as remote monitoring, predictive maintenance, and digital twins will further integrate into production processes, improving automation and flexibility across the line. Supported by AI and big data, blow molding is expected to become even more precise and energy-efficient, paving the way for a new era in industrial manufacturing.

.png)