- Showing results for

- CNC Turning Machine

As cycling becomes more popular globally, particularly in the high-end sports bicycle sector, the demand for precision parts is steadily increasing. These components not only play a central role in a bike's performance but are also a direct reflection of the rider's experience. Many international brands are now placing a greater emphasis on personalized design and high-quality machining to meet the diverse needs of different users.

2025-08-14 17:08:46

Founded in 1987, Yung Cheng Shun Industrial Co., Ltd. (YCS) began with a mission to "provide customers with reliable, high-quality precision parts." For over three decades, it has evolved from a small traditional lathe workshop into an internationally renowned CNC precision machining manufacturer, trusted by OEM and ODM clients across various industries.

2025-08-14 16:37:42

As CNC machining and precision metal processing continue to grow, machine tools release large amounts of oil mist, atomized coolant droplets, smoke, and fine oil particles during operation. Prolonged exposure to such environments not only endangers operator health but also affects machine accuracy and maintenance costs. Therefore, highly efficient oil mist filtration equipment has become an essential asset in modern machining facilities.

2025-08-13 11:09:38

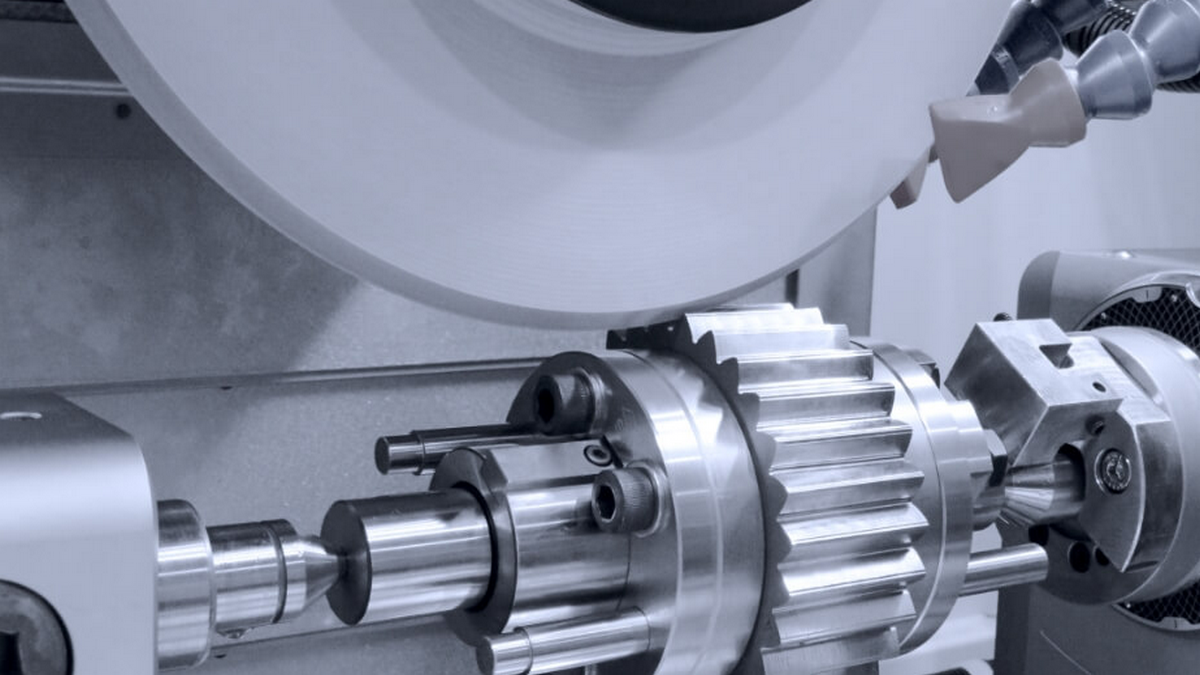

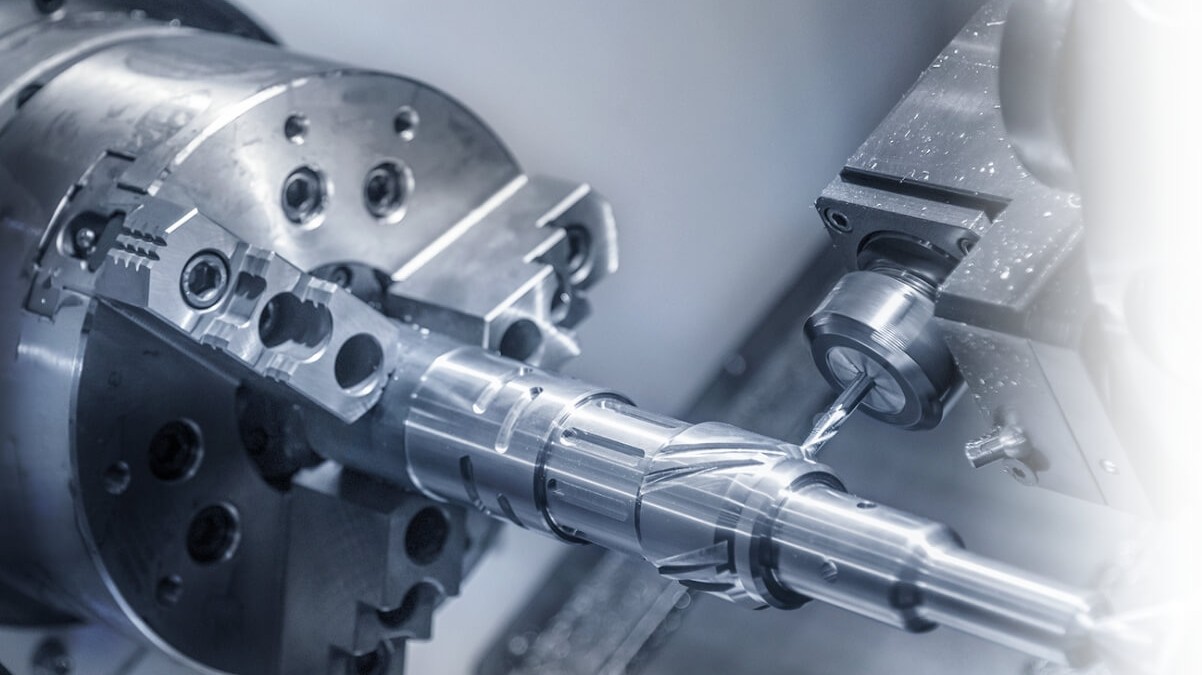

As global manufacturing competition intensifies, the precision machining industry is facing unprecedented challenges: parts are becoming smaller and more geometrically complex, machining accuracy requirements are rising, and delivery deadlines are increasingly compressed. As a core piece of equipment in this field, the CNC toolroom lathe is undergoing a profound transformation driven by both technological breakthroughs and evolving market demands.

2025-08-12 14:42:46

High-precision lathes and toolroom lathes specialize in producing small, high-accuracy components, often used in prototype development and sample manufacturing. As CNC toolroom lathes become increasingly widespread, the industry is moving toward digital and automated control to shorten production cycles and improve machining quality and consistency.

2025-08-12 14:32:21

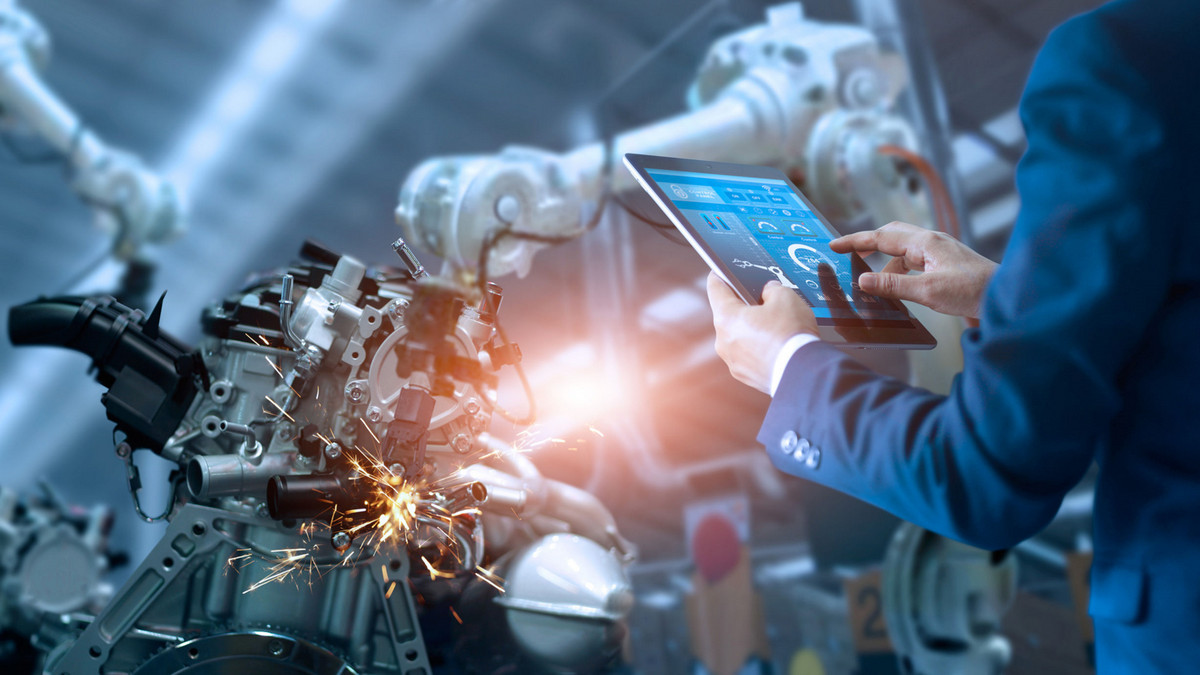

CNC (Computer Numerical Control) machine tools are automated devices that control machining processes through computer programming. Known for their high efficiency, precision, and stability, they are widely used across industries such as aerospace, automotive, mold making, electronics, medical, and energy. With the rise of Industry 4.0 and smart manufacturing, CNC technology continues to evolve toward multi-axis machining, intelligent control, remote monitoring, and integrated processes. This widespread adoption not only enhances manufacturing performance but also reshapes the workforce, shifting traditional manual skills toward digital operation and system integration—bringing greater production flexibility and competitiveness to businesses.

2025-08-08 16:05:07

The traditional manufacturing industry relied on skilled artisans manually operating lathes, meticulously shaping perfect components with hand tools. However, as times have rapidly changed, lathes have evolved from manual machines into automated equipment. Now, instead of manual carving, engineers can produce parts simply by inputting a program. The emergence of big data, AI, and the Internet of Things (IoT) has brought another wave of impact to the industry, signaling that a new manufacturing revolution is on the horizon.

2025-08-08 10:28:10

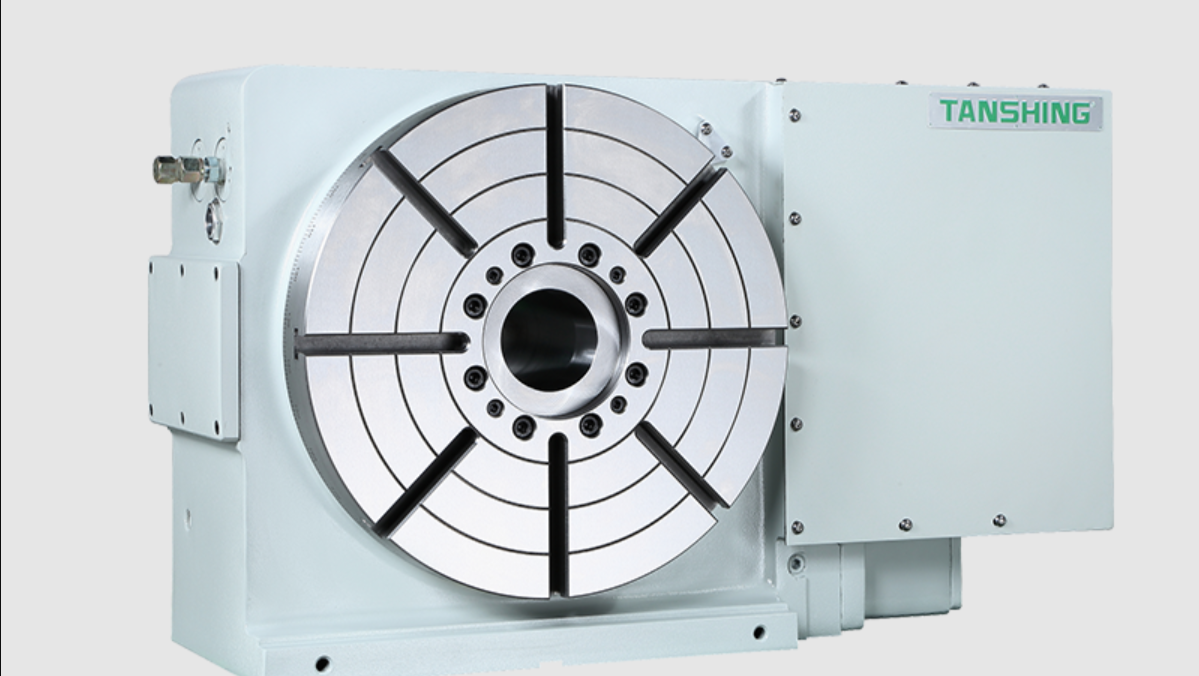

With increasing industrial automation worldwide, CNC rotary tables equipped with 4- and 5-axis capabilities have seen substantial adoption—particularly in applications requiring high precision and heavy load handling. These “smart turntables” enhance tool efficiency, machining accuracy, and production rhythm. According to Verified Market Reports, the global CNC rotary table market was valued at US $1.5 billion in 2024, projected to reach US $2.8 billion by 2033 at a 7.5% CAGR.

2025-08-04 15:48:35

The CNC machining industry has seen amazing developments and innovations since the incorporation of computer programming into machining operations. CNC machining is a highly competitive industry, and among the multitude of companies striving to excel in this field, Chevalier Machinery Inc. has grown to be a leading manufacturer of CNC high-precision surface and form grinders, machining centers, turret milling machines, and multi-function lathes.

2024-05-08 15:52:26

NC is the most important revolution since the first industrial revolution in the manufacturing industry. Since its successful development in 1950, NC technology has been undergoing important developments in hardware and software.

2023-06-01 14:23:33

The turning process is to make the material reach the desired shape by removing the material, and its machining accuracy is high and there is no mold restriction. But the production cost is high and the processing speed is slow.

2022-08-30 13:09:15

In the manufacturing application of digital technology, CNC machining has been focusing on the improvement of the precision and accuracy of material processing, as well as the improvement of the operating process, so that most production processes can be completed on one machine, thereby improving overall production and efficiency, and reducing costs.

2022-05-05 14:24:22

A CNC machining center is a kind of CNC machining machine which has had many other functions added. Combining milling, boring, drilling, tapping, and threading functions into one machine, enables a machining center to perform multiple processes.

2022-03-17 14:42:10

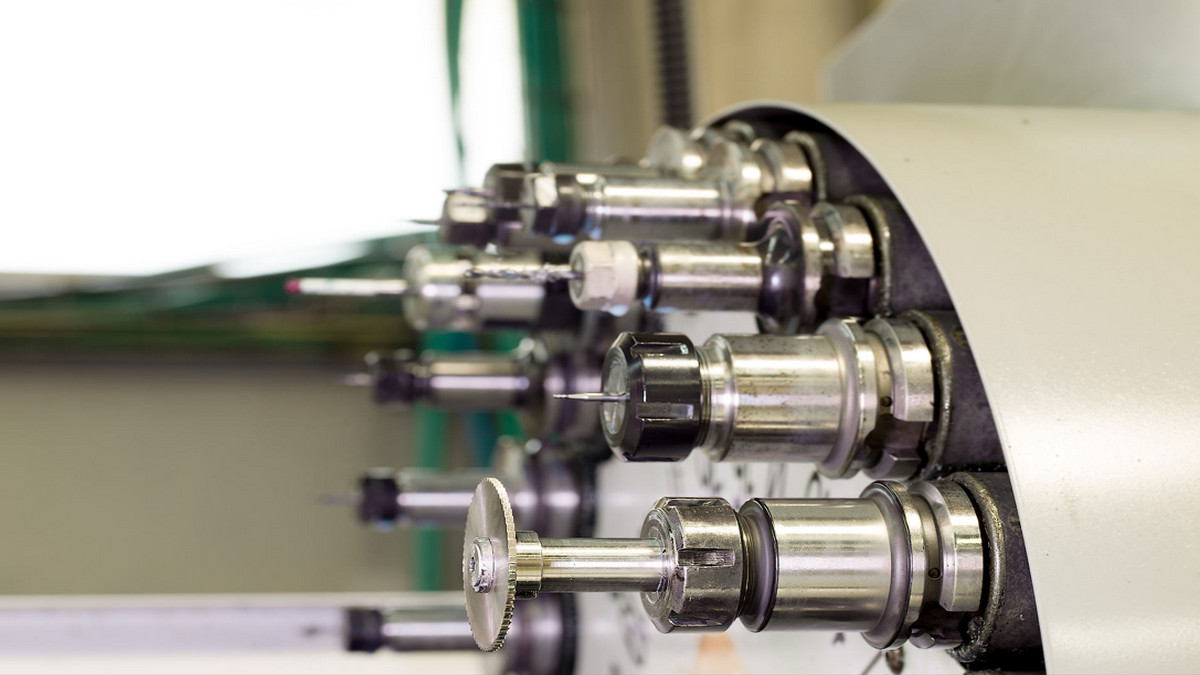

Lico CNC Lathe Machinery Co., Ltd was established with more than 40 years of accumulated industry experience. It has been engaged in the manufacture of cam automatic lathes for 20 years, and its products are sold all over the world. All types of machinery are made of precision, ultra-high function, durable, suitable for mass production. All parts are interchangeable and easy to maintain.

2020-09-10 11:34:26

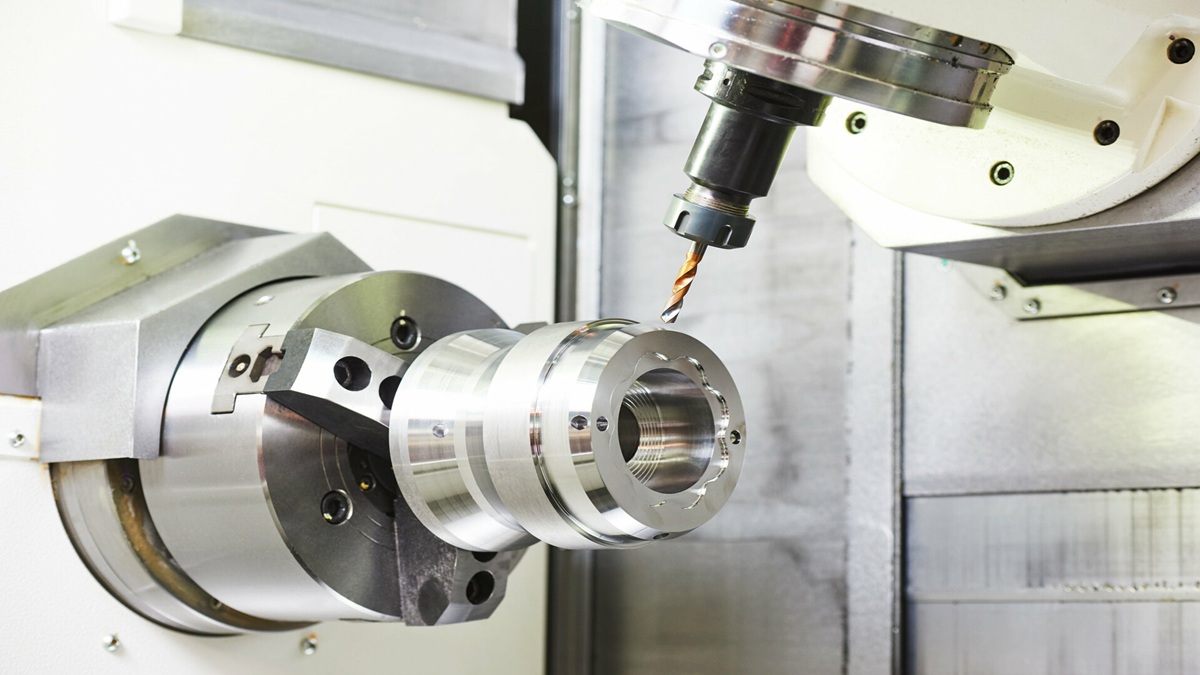

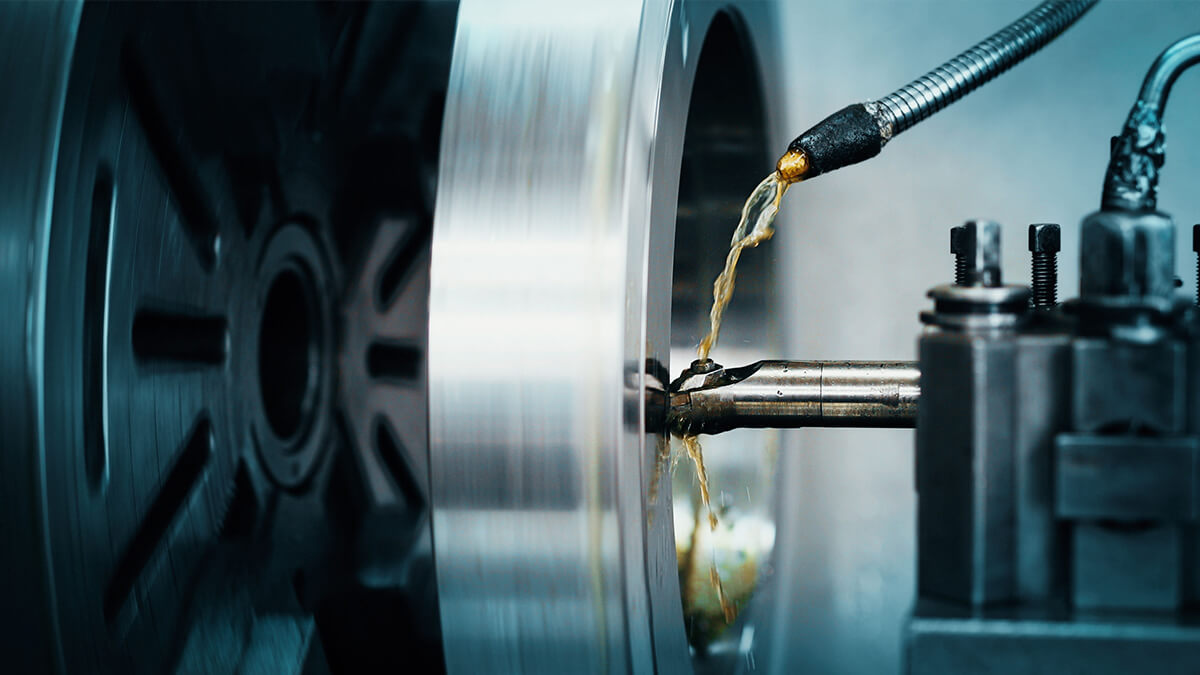

Computer numerical control (CNC) turning is a subtractive machining process where a cutting tool is placed against a spinning piece to take material off. This is usually done with a CNC lathe or turning center which cuts the material including wood, metal, and plastic. This article will cover the different types of CNC lathes, their components, and which type you could use for your next project.

2020-05-14 09:25:28

CNC turning centers and lathe machinery look are the same, but they usually refer to slightly different machine tools. Lathes can usually only turn, while turning centers can be more advanced. These machines can perform end face, thread, knurling, drilling, boring, reaming, and taper turning. Horizontal CNC lathes are more common, while vertical machine tools use gravity. CNC turning centers can benefit from predictive maintenance.

2020-05-08 15:36:48

Agree

.jpg)