What is CNC Turning Machine?

CNC turning centers and lathe machinery look are the same, but they usually refer to slightly different machine tools. Lathes can usually only turn, while turning centers can be more advanced. These machines can perform end face, thread, knurling, drilling, boring, reaming, and taper turning. Horizontal CNC lathes are more common, while vertical machine tools use gravity. CNC turning centers can benefit from predictive maintenance.

Published: May 08, 2020

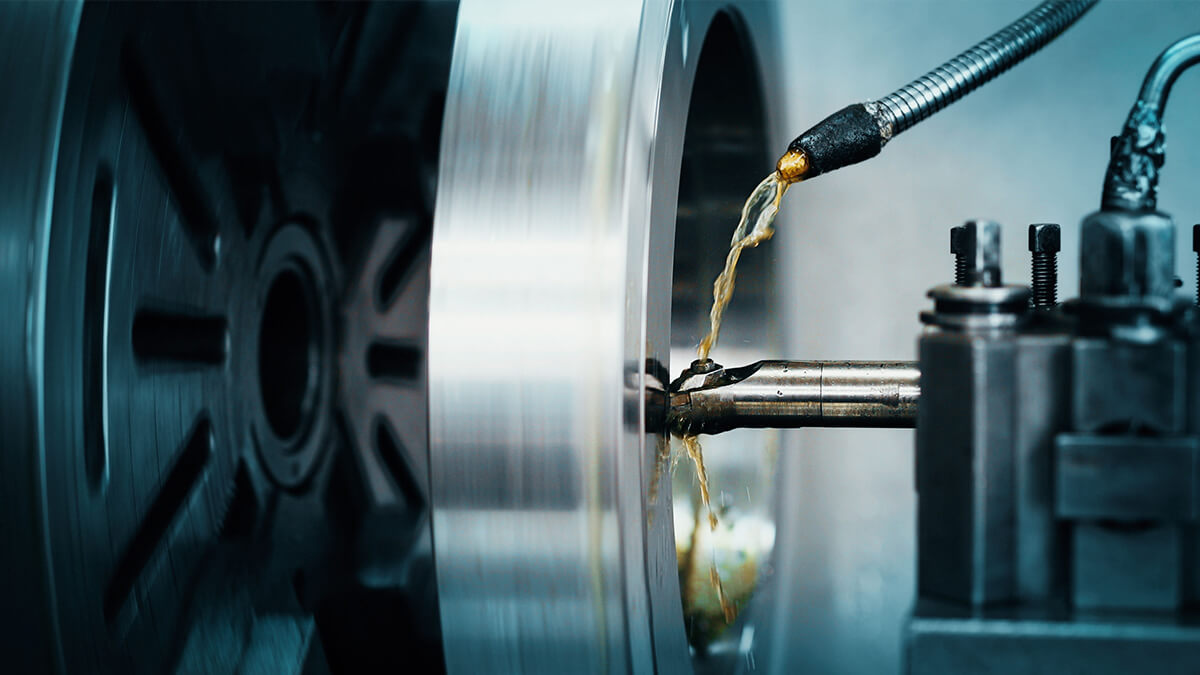

In CNC turning, bars of material are held in a chuck and rotated (spun) while various tools are “pressed” to the bar stock to remove material and create the desired shape and features. When the component requires both turning and milling features (pictured above), the bar rotation can be stopped to allow for milling (usually flat area). This technique allows for a wide range of shapes, sizes, features, and even material types.

CNC turning centers have tooling mounted on a turret for correct placement against the bar stock. We use CNC turning centers with “live” tooling, which allows us to program an extensive range of features on an individual component such as drilled holes, slots, and milled surfaces. CNC turning centers without live tooling would be limited to the number and types of features that can be produced on a component.

- The starting material, though usual round, can be other shapes such as hexagons. Each bar shape and size may require a specific “collet” (a subtype of chuck—that forms a collar around the object) to correctly position the bar for machining.

- Depending on the bar feeder, the bar length can vary.

- CNC turning centers have tooling mounted on a turret which is computer-controlled.

-

CNC’s with “live” tooling, such as those at Pioneer Service, can also stop the rotation and add additional features such as drilled holes, slots, and milled surfaces.

- Some CNC turning centers have one spindle, allowing work to be done all from one side, while other turning centers, such as the one shown above, have two spindles, a main and sub-spindle. A part can be partially machined on the main spindle, moved to the sub-spindle, and have additional work done to the other side of this configuration.

- There are many different kinds of CNC turning centers with various types of tooling options, spindle options, and outer diameter limitations.

Which parts are suitable for CNC turning?

While a lot of factors go into determining if a part can be made most cost-effectively on a specific CNC turning center, some things we look at are:

- How many parts are needed short-term and long-term? CNC turning centers are generally good for prototypes to short-run volumes.

- What is the largest OD on the part? For the CNC turning centers at Pioneer Service, the maximum OD for collated (bar feed-capable) parts is 2.5.”

- Parts over 2.5″ OD are chucked individually, which depending on volume, can contribute to the price.

- Parts under 1.25″ OD and medium to high volume may be a better fit for the Swiss screw machines.

- If a part can be made both on the CNC turning center and on a 32 mm Swiss Screw Machine factors such as projected volume and lead-time are critical for making the best call on which to use.

The main difference between CNC and traditional lathes

The traditional lathes are usually limited to two axes for machining, while the CNC lathes can have up to six machining axes and even milling tools.

- Horizontal CNC lathe is one of the most commonly used machine tools, with all the functions of a conventional lathe, but they are controlled by a computer and are mainly used for turning and boring.

- The vertical CNC lathe fixes the work piece from the bottom (instead of holding the side fixture horizontally), and then rotates the work piece like the top. This is very useful for workshops with limited space and when dealing with particularly sturdy and heavy work pieces.

- The horizontal turning center is a closed CNC lathe with integrated milling and drilling functions. The turning center can also include a travel tool holder, more tooling shafts, coolant overflow, a tail stock separate from the carriage, and sometimes a conveyor belt.

- Vertical turning center is a combination of horizontal turning center and CNC milling machine.

Published by May 08, 2020

Source :pioneerserviceinc,

Source :pioneerserviceinc

.jpg)

.png)